Laying method and laying system of middle support of composite energy-saving glass

An intermediate support, energy-saving glass technology, applied in glass molding, glass re-molding, glass production and other directions, can solve the problems of low efficiency of intermediate supports, inability to guarantee support, leakage, replay and other problems, and achieve The effect of stable position, simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

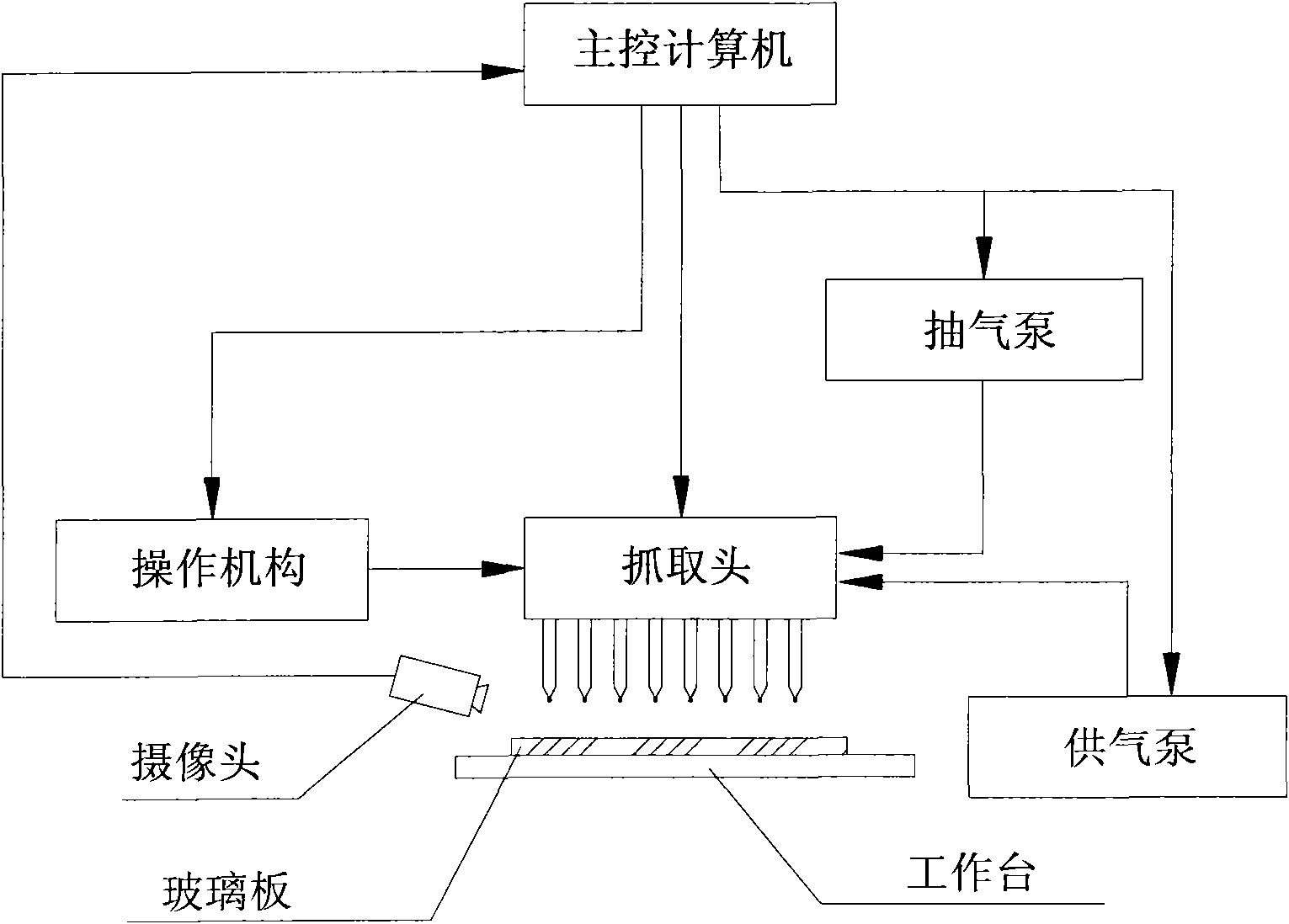

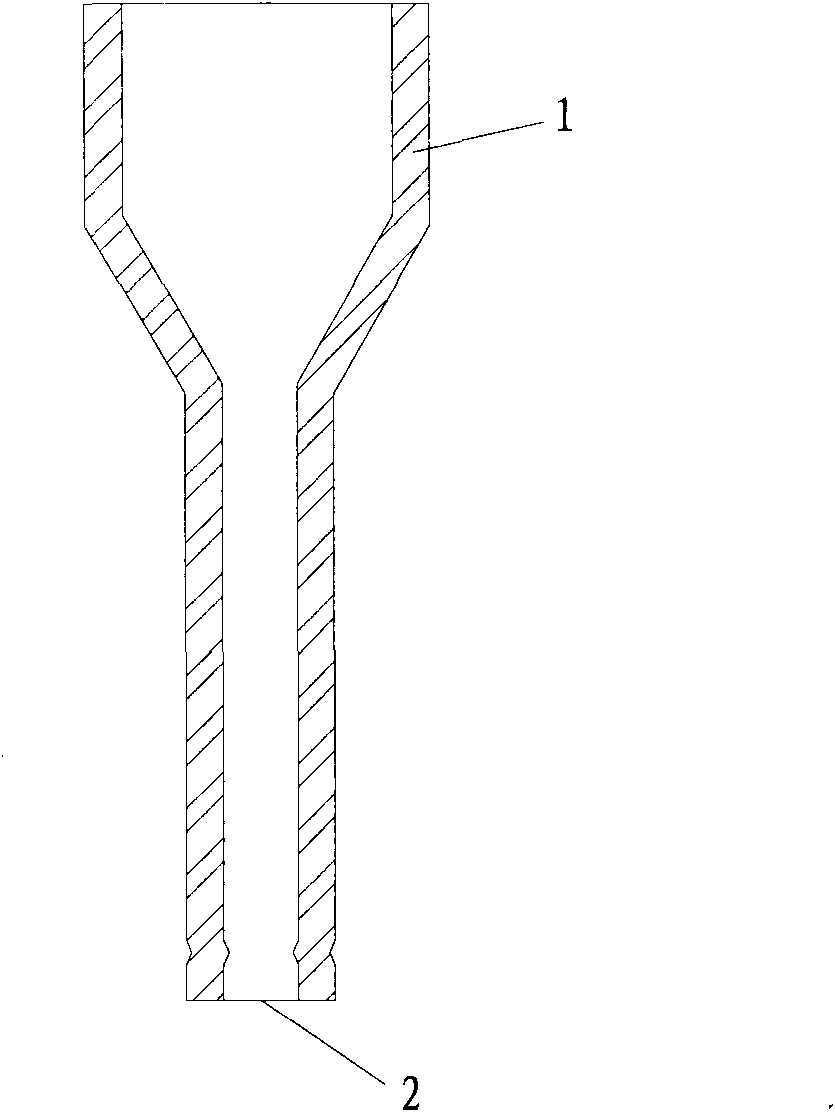

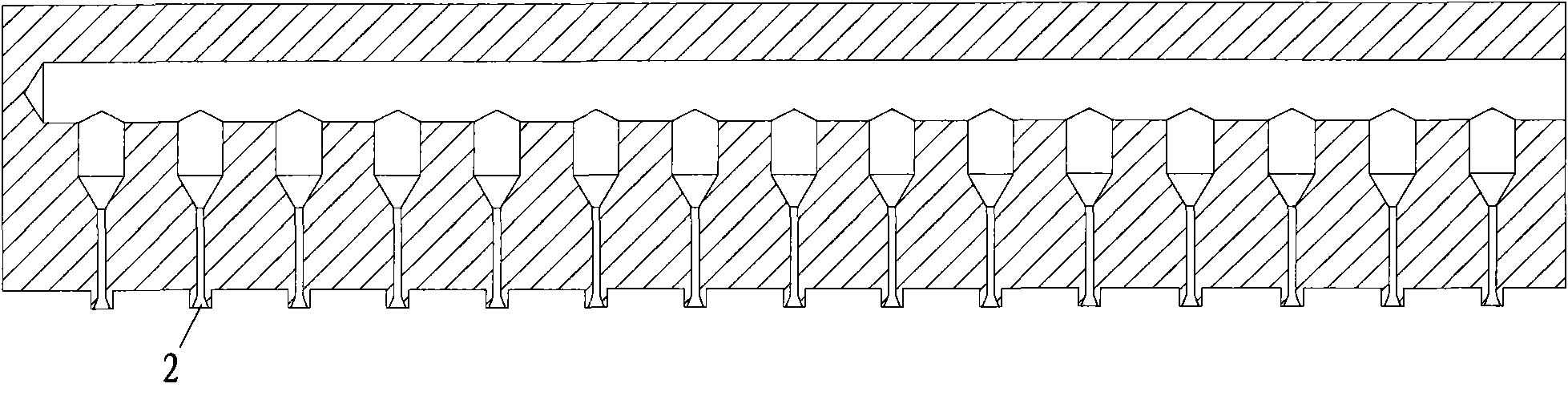

[0037] figure 1 The composite energy-saving glass intermediate support deployment system shown in includes a worktable, an operating mechanism, a grabbing head, an air pump, an air supply pump, a camera, and a main control computer; the glass plate to be placed is supported and positioned on the workbench above; the grabbing head is installed on the operating mechanism, and can move up and down, left and right, and front and rear directions relative to the surface of the glass plate to be placed with the intermediate support under the manipulation of the operating mechanism; the grabbing head is provided with a size that matches the intermediate support The suction port is connected to the air suction pump and the air supply pump respectively through the pipeline; the air suction pump is used to make the suction port on the grab head generate negative pressure for sucking the intermediate support; the air supply pump is used to suck the air on the grab head Air is supplied fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com