Concrete pouring and vibrating dynamic visualization monitoring method

A technology for pouring, vibrating, and concrete, which is applied in construction, building structure, and processing of building materials. , Avoiding leakage/under-vibration/over-vibration/construction of cold joints, and the effect of timely, accurate and reliable treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

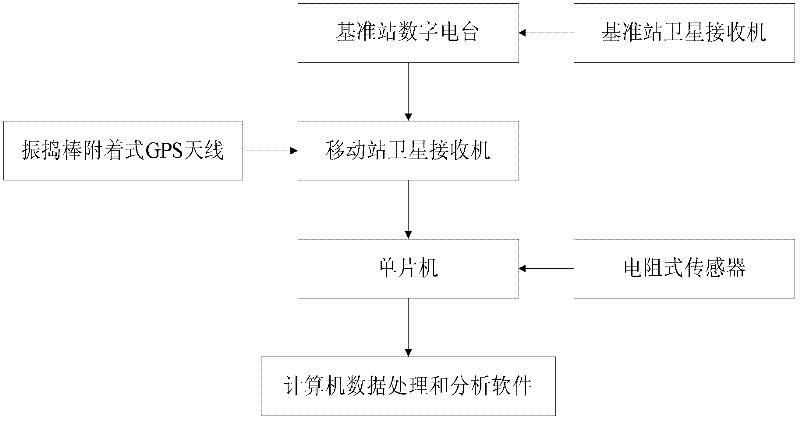

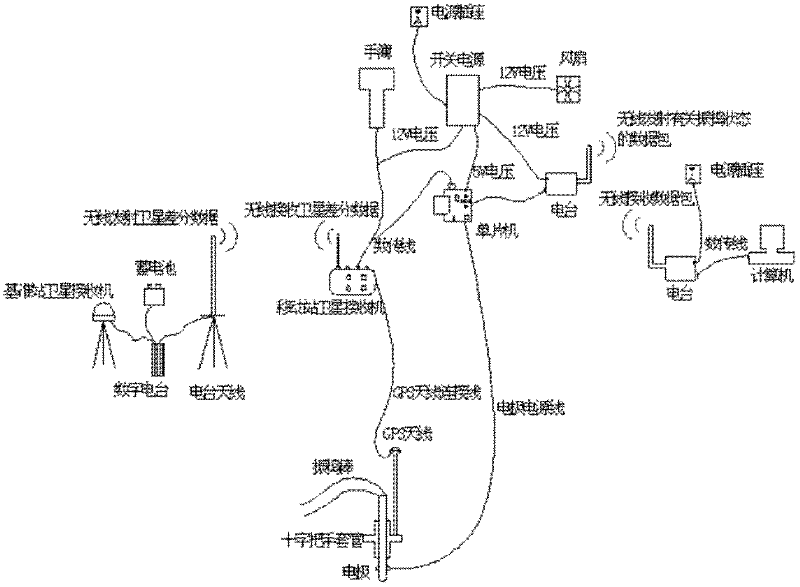

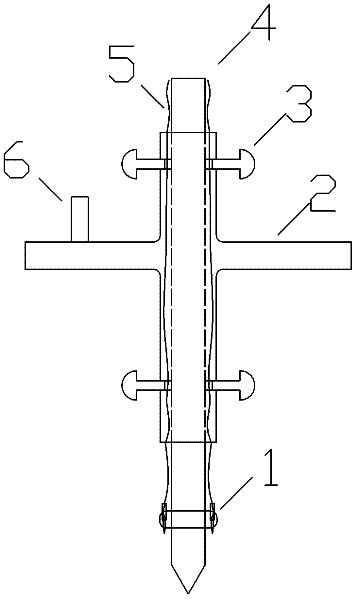

[0020] Such as Figures 1 to 4 As shown, the concrete pouring vibrating dynamic visual monitoring method according to the present invention includes the following steps: 1) Measurement of the vibrating track and the vibrating time of the vibrating rod - firstly, a vibrating rod is installed at one end of the vibrating rod for measuring The electrode of the concrete potential to be vibrated, and the GPS antenna is installed on the other end; secondly, the vibrator is inserted and removed from the concrete to be vibrated, and when the vibrator is inserted and removed from the concrete to be vibrated, the traditional RTK working mode is used to control the GPS antenna. The fed back data is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com