Bearing block

A bearing assembly, bearing wall technology, applied in the direction of bearings, shafts and bearings, shafts, etc., can solve problems such as bearing damage and bearing hole enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

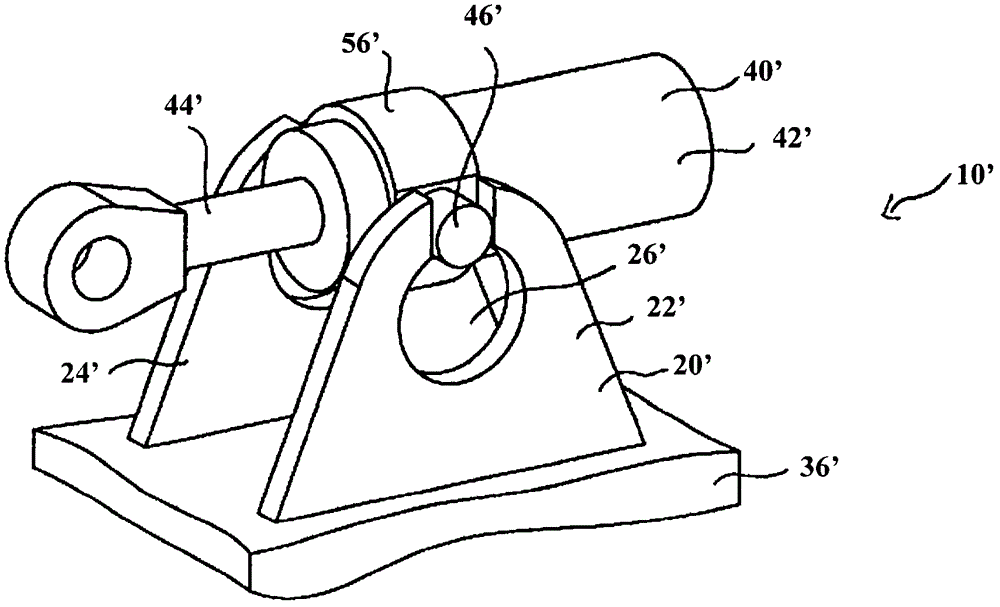

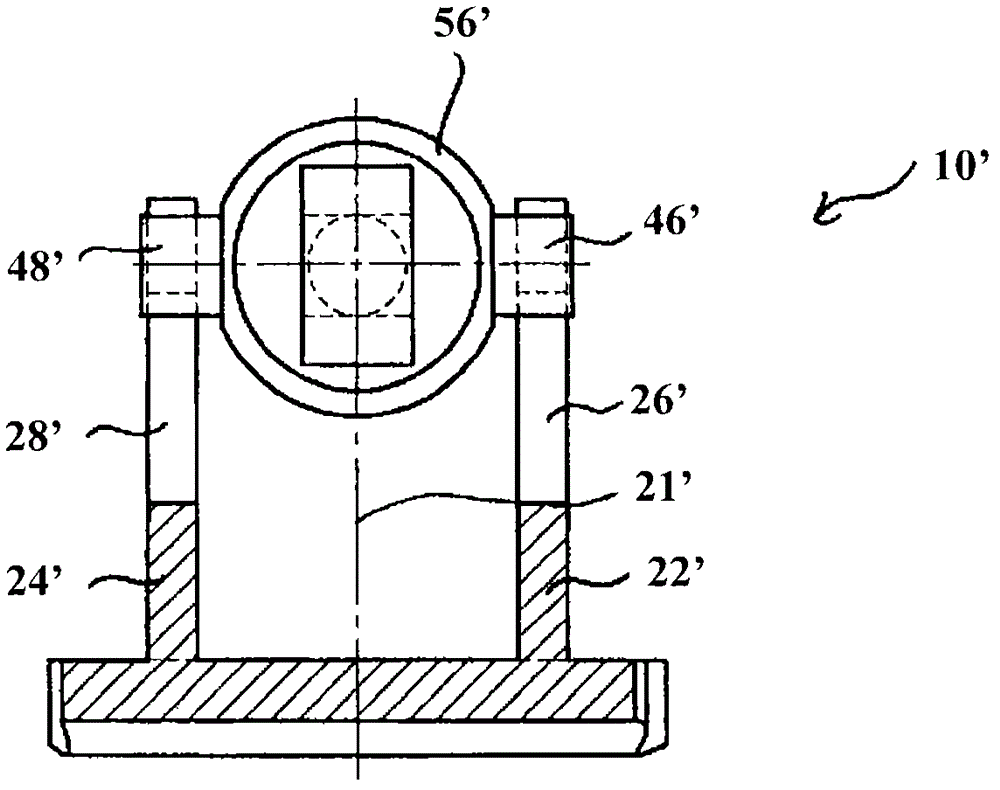

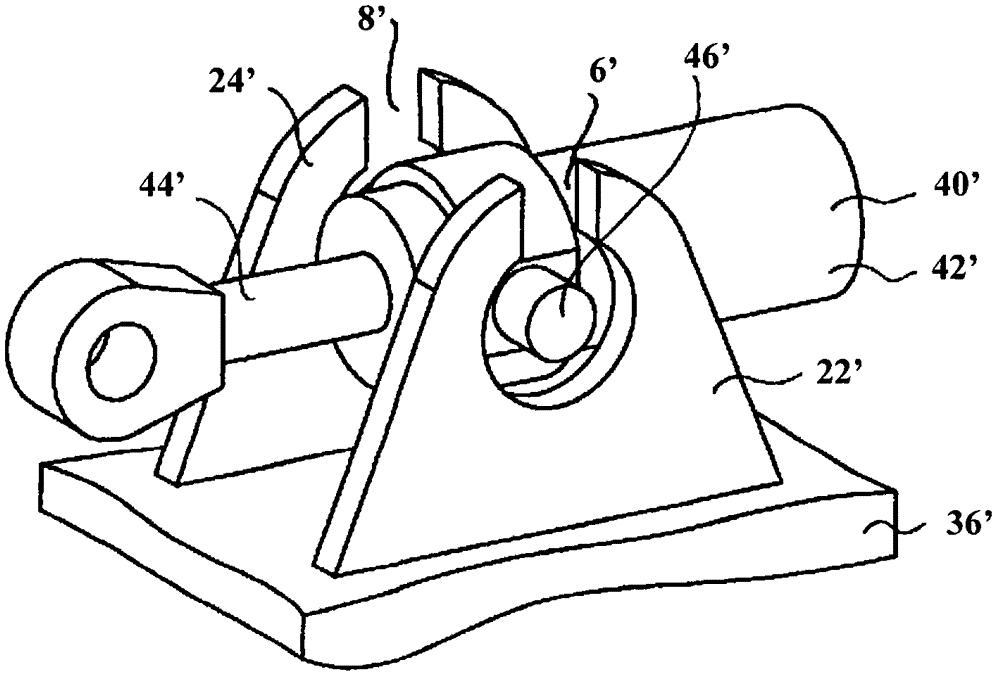

[0065] The bearing assembly 10' with open bearing holes 26', 28' according to the prior art Figure 1 to 6 Shown in.

[0066] The bearing assembly 10' includes a bearing body 20' with two bearing walls 22', 24' arranged parallel to each other, and the bearing wall is mounted at the base element 36'. A bearing hole 26', 28' designed in a partial circular shape is constructed in each of the bearing walls 22', 24'. The bearing holes 26', 28' are open to the outside, and each has an introduction port 6', 8', which are arranged opposite to each other.

[0067] In addition, the bearing assembly 10' includes an adjusting cylinder 40' with a cylinder housing 42' and a displacement piston, and the displacement piston has a piston connecting rod 44'. The adjusting cylinder 40' is supported at the bearing body 20' around the axis of rotation 52' ( Figure 4 ). In addition, the adjusting cylinder 40' has two journals 46', 48', which can be introduced into or removed from the bearing holes 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com