Preparation method of perovskite thin film with light control structure and optical device

A technology of perovskite and light regulation, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of poor controllability, high cost, high pressure, etc., and achieve improved optoelectronic performance, low cost, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 has the preparation method of the perovskite film of photoregulatory structure

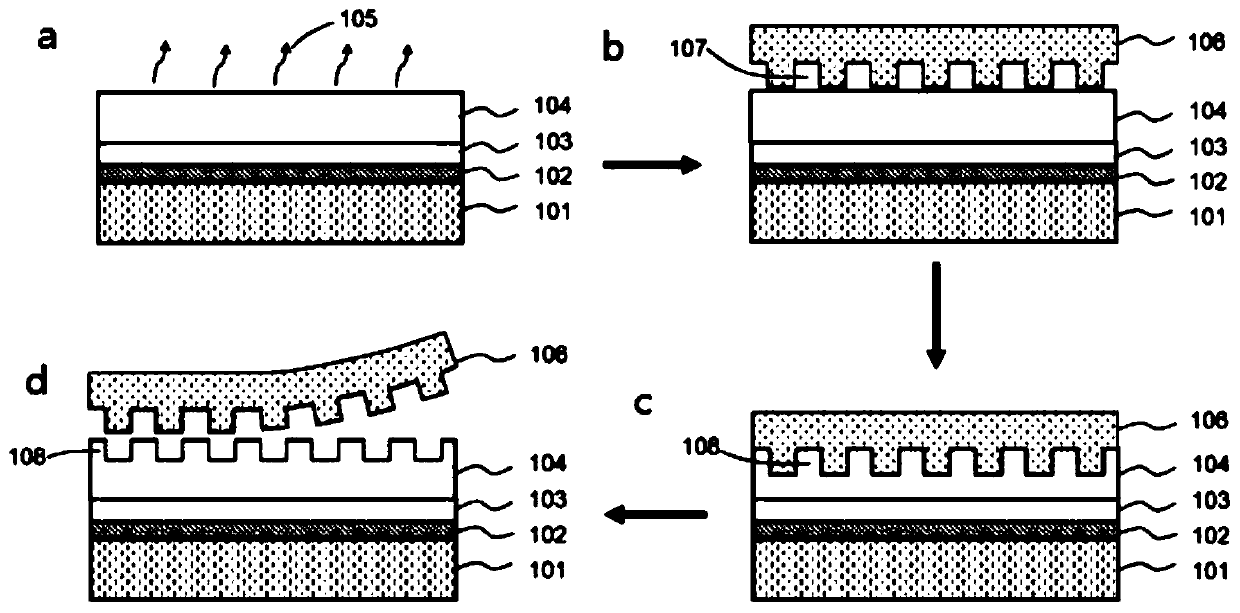

[0046] Such as figure 1 As shown, the preparation method of the perovskite film with light-tuning structure is as follows:

[0047] After the substrate substrate 101 made of glass is cleaned with detergent, a patterned ITO thin film is sputtered on one side as the transparent electrode layer 102 . Place the substrate substrate with ITO in detergent, deionized water, acetone, ethanol, and deionized water in sequence, and ultrasonically clean it for 10 minutes each time. After cleaning, dry it with a nitrogen gun, and put the substrate substrate into the ultraviolet UV ozone treatment was carried out in an ozone machine for 10 min.

[0048] The above-mentioned substrate substrate was transferred to a glove box, and a layer of PEDOT:PSS was spin-coated on the surface of the substrate as the hole transport layer 103, and the rotation speed was controlled to 4000rpm, and the time ...

Embodiment 2

[0053] The preparation method of embodiment 2 solar cells

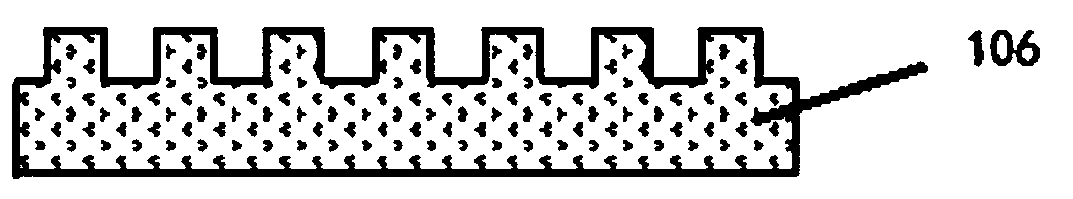

[0054] When preparing the battery, the shape of the nano concave-convex structure used is a one-dimensional periodic grating structure, the groove depth is 150nm, the period is 800nm, and the duty ratio is 0.6.

[0055] The specific manufacturing process of each layer structure of the transparent electrode layer 102, the hole transport layer 103, the perovskite film 104, the electron transport layer 15, the buffer layer 16 and the metal electrode 17 on the substrate substrate 101 can be selected from the solution method respectively. Methods such as spin coating, vapor deposition, sputtering, or other known methods, preferably, in this embodiment, the specific steps are as follows:

[0056] (1) Ordinary float glass substrate After the substrate 101 is cleaned with detergent, a patterned ITO film is sputtered on one side as the transparent electrode layer 102 . Place the substrate substrate with ITO in detergent, deio...

Embodiment 3

[0063] The preparation method of embodiment 3 light-emitting diodes

[0064] When preparing the light-emitting diode, the shape of the nano concave-convex structure used is a one-dimensional periodic grating structure, the groove depth is 150nm, the period is 400nm, and the duty ratio is 0.6.

[0065] The specific method is as follows:

[0066] (1) Ordinary float glass substrate After the substrate 101 is cleaned with detergent, a patterned ITO film is sputtered on one side as the transparent electrode layer 102 . Place the substrate substrate with ITO in detergent, deionized water, acetone, ethanol, and deionized water in sequence, and ultrasonically clean it for 10 minutes each time. After cleaning, dry it with a nitrogen gun, and put the substrate substrate into the ultraviolet Carry out ultraviolet ozone treatment in the ozone machine for 10 minutes;

[0067] (2) Transfer the substrate substrate processed in step (1) to a glove box, spin-coat a layer of PEDOT:PSS on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com