126kv breaker arc extinguish chamber centring frock

A 126kv, circuit breaker technology, which is applied in the manufacture of circuits, emergency protection devices, emergency protection devices, etc., can solve problems such as non-compliance with alignment requirements, insignificant influence of main circuit resistance, and inappropriate products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

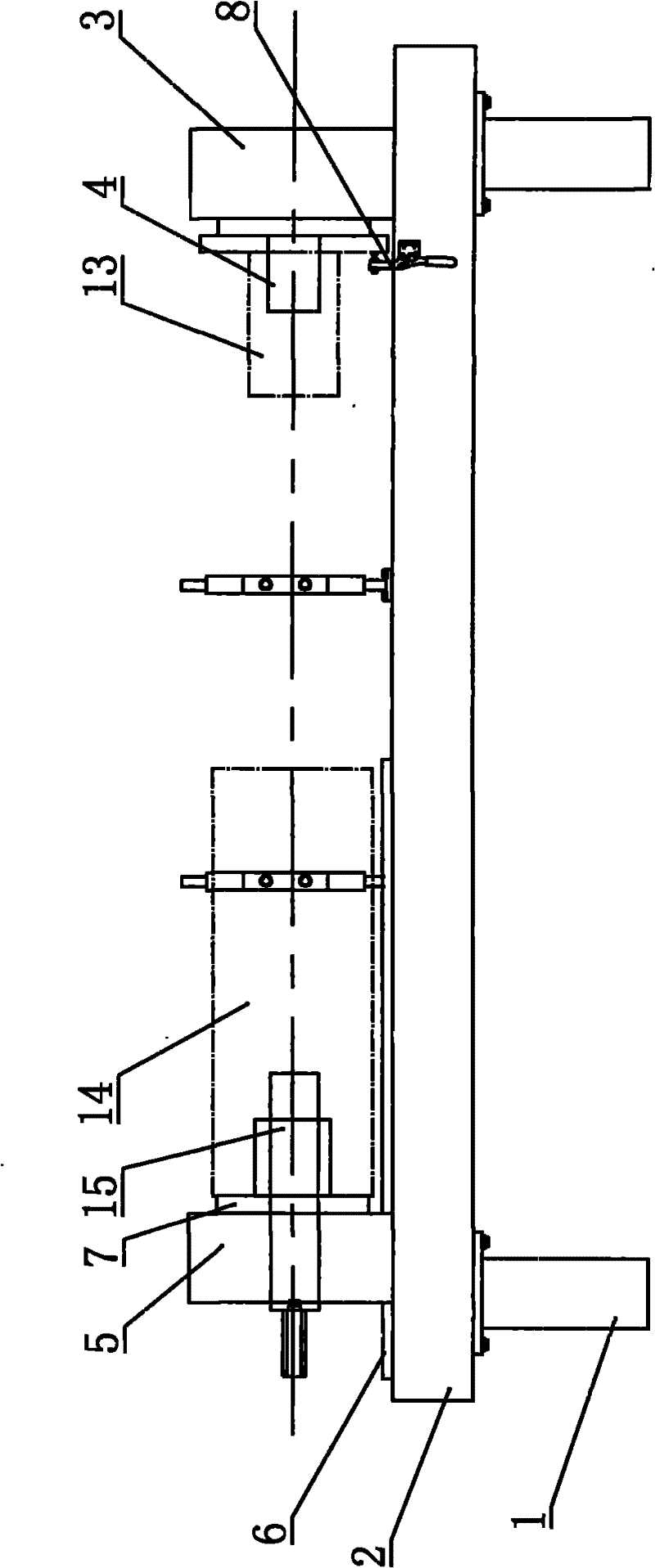

[0016] Such as figure 1 As shown, it includes a frame 1, a centering platform 2, a fixed fixture table 3, a fixed fixture table round table 4, a movable fixture table 5, a linear guide rail 6, and a movable fixture table round table 7.

[0017] A centering platform 2 is arranged on the above-mentioned frame 1, and a fixing fixture platform 3 is fixed on the right end of the centering platform 2. The inner surface of the fixing fixture platform 3 is provided with a fixing fixture platform round platform 4, which is a stepped cylinder. The small-diameter cylinder at the end can just fit into the opening at the bottom of the support seat of the circuit breaker's arc extinguishing chamber. A clamping mechanism is installed on both sides of the round table to press the support seat of the circuit breaker interrupter so that the lower end surface is close to the shoulder of the round table 4. The clamping mechanism is a common clamping tool on the market: quick toggle clamp 8 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com