Zipper slider and zipper head with same

A technology of sliders and zippers, applied in the direction of application, sliding fastener components, fasteners, etc., can solve the problems of complex assembly process and complex structure of sliders, and achieve the effects of simple structure, improved safety, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

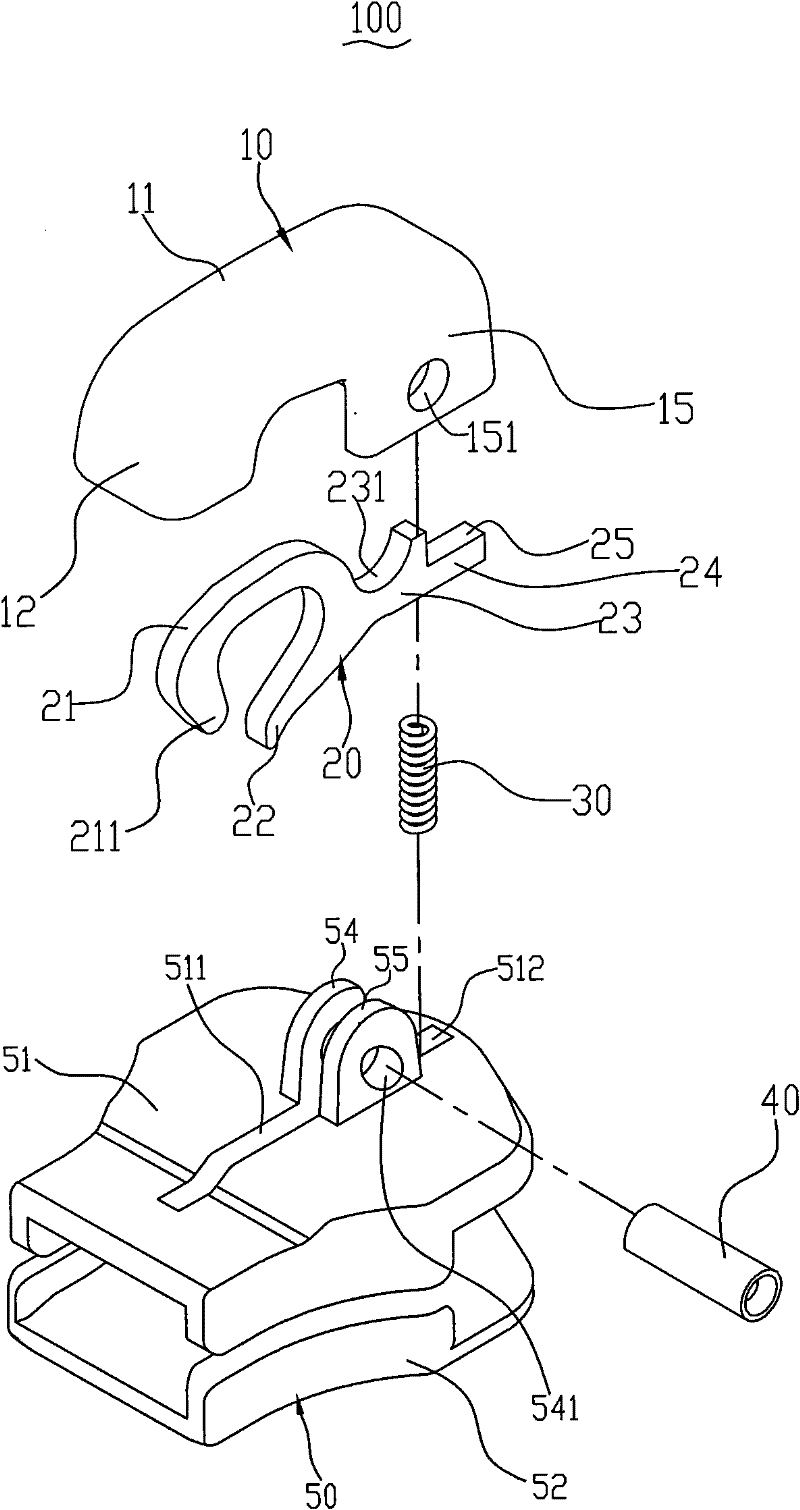

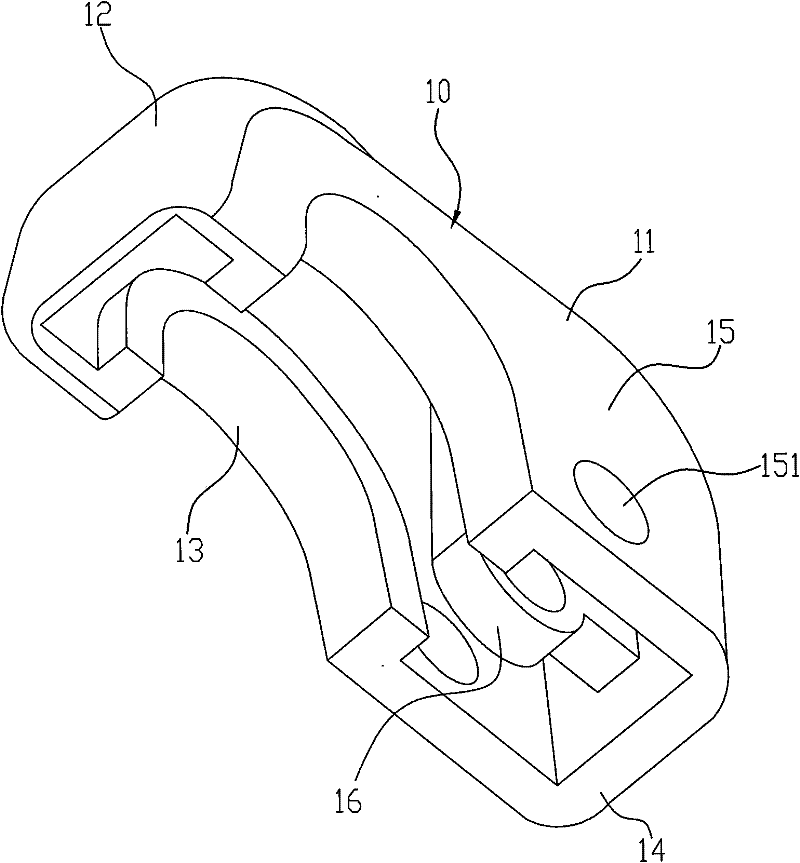

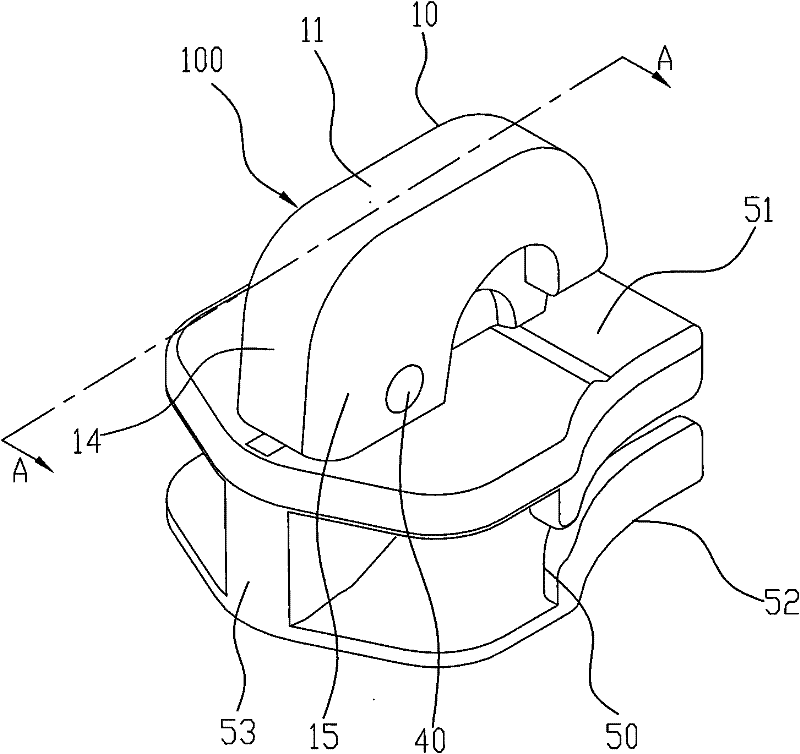

[0037] see figure 1 , figure 2 and image 3 , figure 1 It is an exploded perspective view of the first embodiment of the zipper slider 100 of the present invention. The zipper slider 100 includes a cap 10 , a self-locking element 20 , an elastic element 30 , a circular tube 40 and a slider body 50 . The self-locking element 20 is placed on the slider body 50 . The cap 10 is fixed on the slider body 50 through the circular tube 40 and is covered on the self-locking element 20 . The elastic element 30 is fixed between the cap 10 and the slider body 50 .

[0038] The slider body 50 includes an upper wing plate 51, a lower wing plate 52 and a guide post 53, the upper wing plate 51 and the lower wing plate 52 are connected by the guide post 53 to form a substantially Y-shaped slideway For the chain teeth (not shown) of a zipper to pass through. An elongated groove 511 and a through hole 512 are disposed on the upper wing 51 , the through hole 512 communicates with the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com