Carriage rail for sliding mechanism of extruder

A technology of sliding mechanism and bracket guide rail, which is applied in the field of bracket guide rail, can solve problems such as difficult maintenance, difficult disassembly, instability, etc., and achieves the effect of improving durability, improving production efficiency, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

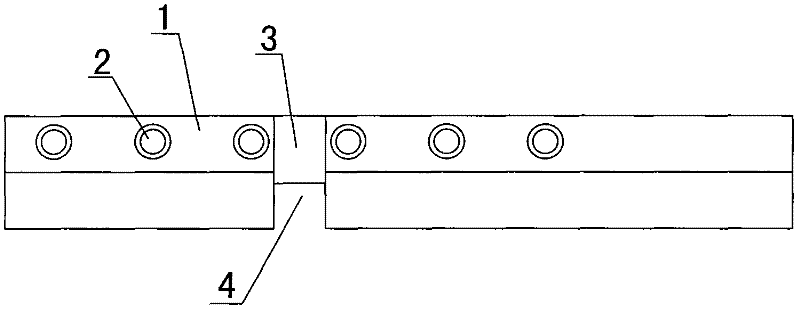

[0011] Such as figure 1 As shown, the bracket guide rail of the extrusion rod sliding mechanism of the present invention includes a guide rail piece 1, and a row of counterbore holes 2 is evenly distributed on the upper side of the guide rail piece 1; Connected by the extension piece 3 provided in the middle, the guide rail sheet 1 at the bottom of the extension piece 3 is provided with a compression cylinder installation hole 4 for installing the compression cylinder so that the connecting rod passes through the hole to the other side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com