Shakeout screen modeling sand pulverizer

A technology of shakeout screen and pulverizer, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc. problem, to achieve the effect of simple maintenance method, strong crushing ability and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

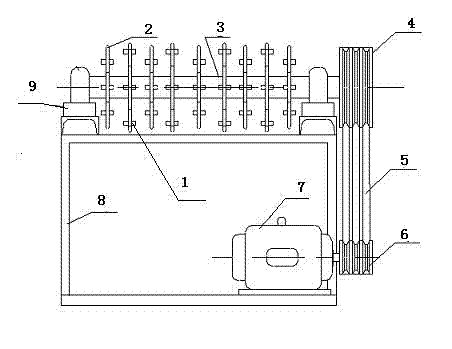

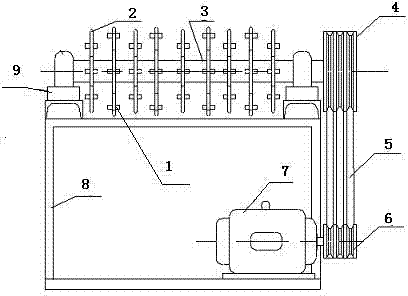

[0008] The present invention will be further described below in conjunction with the accompanying drawings: the falling sand screen type sand pulverizer is composed of a driving motor 7, a motor pulley 6, a V-belt 5, a driven pulley 4, an impeller shaft 3, an impeller 2, a bearing seat 9, a frame 8, and a hopper 10 components; it is characterized in that: each impeller 2 is inlaid with four striking rods 1, the blades of the impellers are staggered and evenly arranged on the impeller shaft 3, the bearing seat 9 is installed on the upper part of the frame 8, and the hopper 10 is installed on the lower part of the frame 8, The drive motor 7 is installed on the outside of the frame 8, and the edge of the impeller 2 is kept at a distance from the shakeout screen.

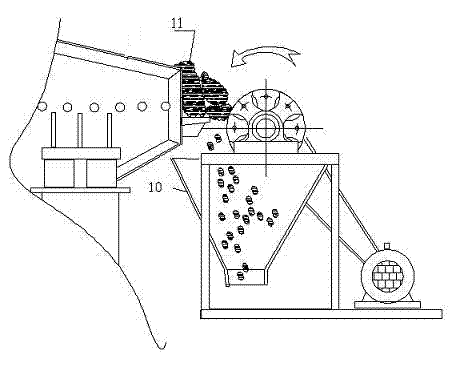

[0009] Such as figure 2 As shown, when the quality of the molding sand is normal and there are no small castings or waste molds, the molding sand normally falls into the hopper 10, and the sand return belt below is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com