Chrome containing tanning agent and preparation method thereof

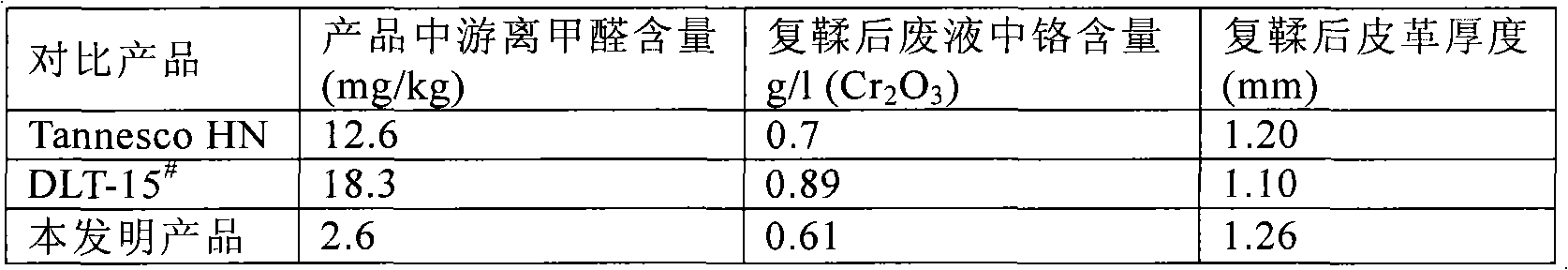

A technology of chrome tanning agent and mixture, which is applied in the field of new chrome-containing tanning agent and its preparation, can solve the problem of high content of free formaldehyde, and achieve the effect of good level dyeing, low chromium content and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

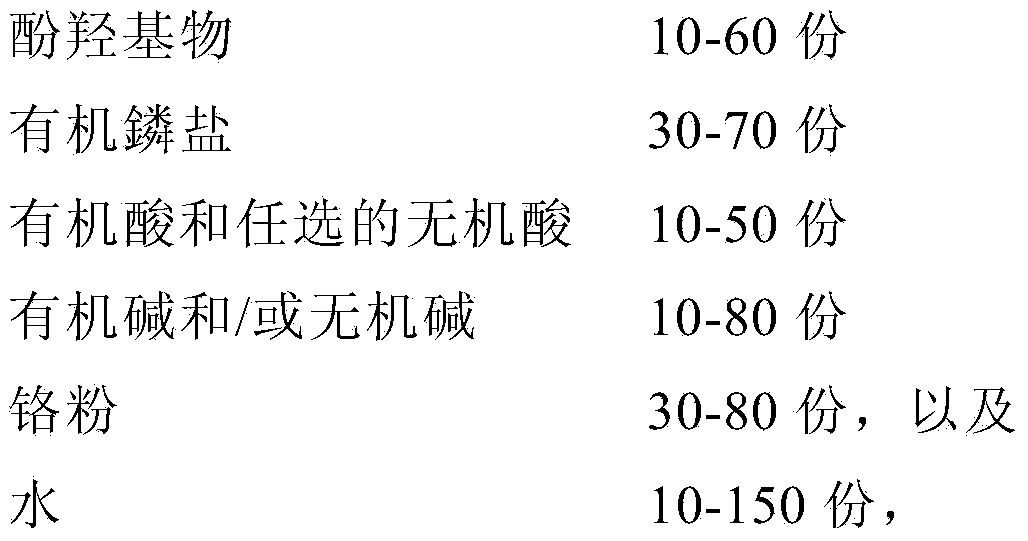

Embodiment 1

[0034] (1) Put 40 parts of bisphenol S in the reactor, dissolve 10 parts of sodium hydroxide with 50 parts of water and put it into the reactor, make the pH value to 7.0-9.0, raise the temperature to 55-60°C, wait After the temperature is stable, slowly add 30 parts of THPS (purchased according to the content of 75% in the aqueous solution), keep the temperature of the reaction system not higher than 65°C, raise the temperature to 95-100°C after the addition, react for 6-8 hours, add water to dilute after cooling down , get material A.

[0035] (2) React all of the above material A and 10 parts of benzoic acid at a controlled temperature of 55-60° C. for 1 hour, then adjust the pH value to 1-2 with 50 parts of 33% dilute sulfuric acid to obtain material B.

[0036] (3) Put 30 parts of chromium powder (for example, basic chromium sulfate), 25 parts of material B, 10 parts of formic acid and 50 parts of water into the reactor, control the temperature at 80-90 ° C, stir and react...

Embodiment 2

[0038] (1) Put 40 parts of bisphenol A, 15 parts of ethanolamine and 20 parts of water in the reactor, make the pH value to 7.0-9.0, raise the temperature to 55-60°C, and slowly add 50 parts of THPC after the temperature is stable (purchased according to the content of 75% in aqueous solution), keep the temperature of the reaction system not higher than 65°C, raise the temperature to 95-100°C after feeding, react for 6-8 hours, add water to dilute after cooling down, and obtain material A.

[0039] (2) All the above-mentioned materials A and 20 parts of glyoxylic acid (purchased according to the content of 40% in aqueous solution) were reacted for 1 hour at a controlled temperature of 55-60 ° C, and then 60 parts of 33% dilute sulfuric acid was used to adjust the pH value to 1-2, get material B.

[0040] (3) Put 60 parts of chromium powder, 40 parts of material B, 10 parts of formic acid and 90 parts of water into the reactor, control the temperature at 80-90°C, stir and react...

Embodiment 3

[0042] (1) Put 30 parts of bisphenol S, 10 parts of bisphenol A, 20 parts of diethanolamine and 40 parts of water in the reactor, make the pH value to 7.0-9.0, raise the temperature to 55-60°C, and wait until the temperature is stable Finally, slowly add 30 parts of THPS (purchased according to the content of 75% in aqueous solution), keep the temperature of the reaction system not higher than 65°C, heat up to 95-100°C after the addition, react for 6-8 hours, add water to dilute after cooling down, and obtain Material A.

[0043] (2) React all of the above material A and 10 parts of benzoic acid at a controlled temperature of 55-60° C. for 1 hour, then adjust the pH value to 1-2 with 48 parts of 33% dilute sulfuric acid to obtain material B.

[0044] (3) Put 40 parts of chromium powder, 35 parts of material B, 10 parts of formic acid and 70 parts of water into the reactor, control the temperature at 80-90°C, stir and react at constant temperature for 3 hours, lower the tempera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap