System for determining EGR degradation

一种EGR冷却器、指示的技术,应用在监视EGR系统领域,能够解决EGR系统劣化、不连续、误报等问题,达到改善参数估算、简化模型调校的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

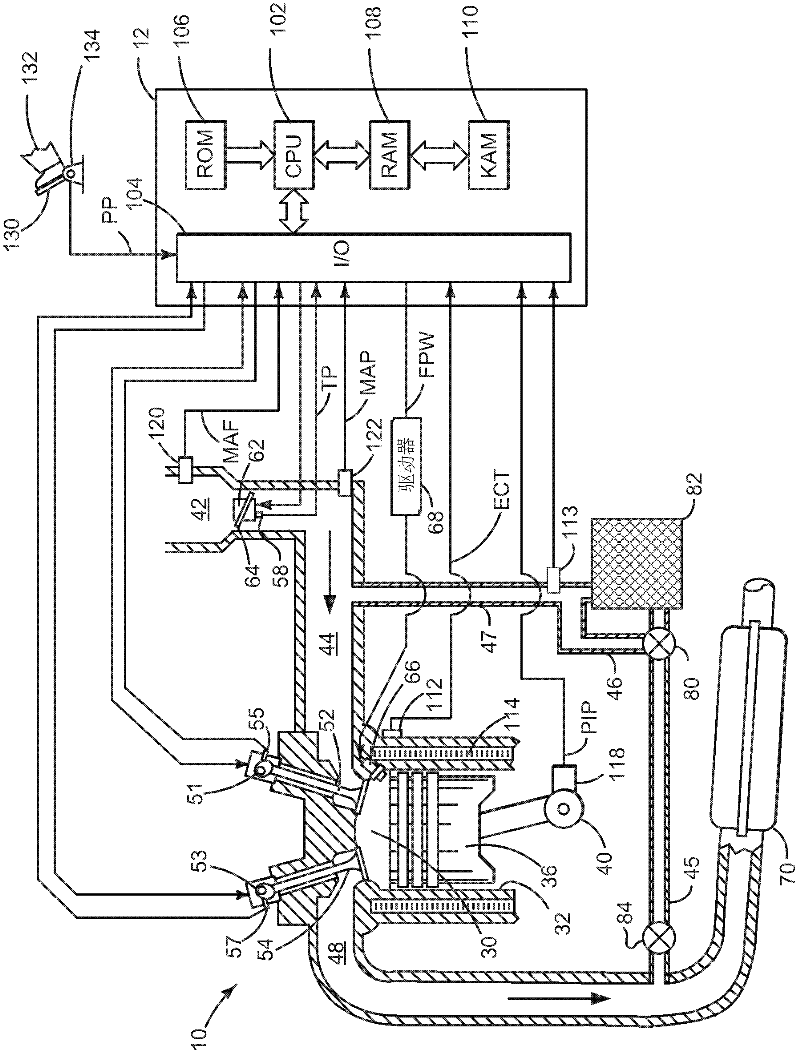

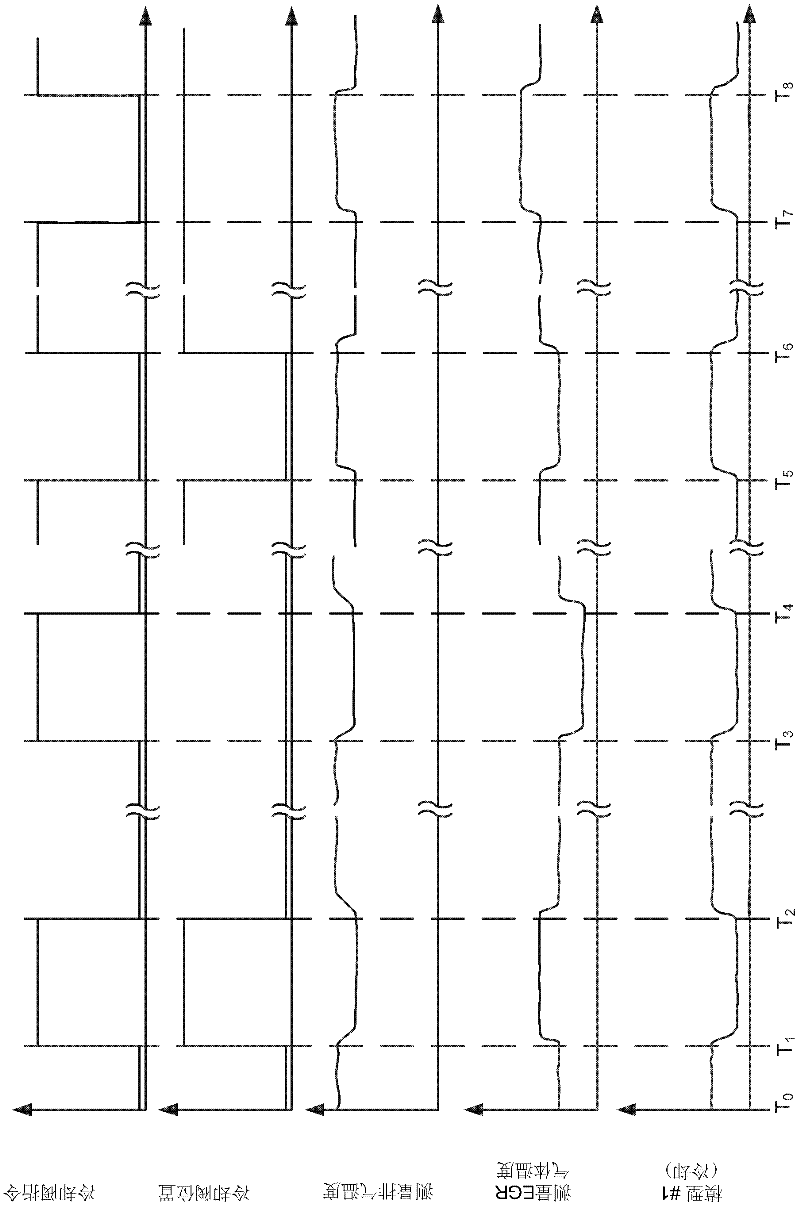

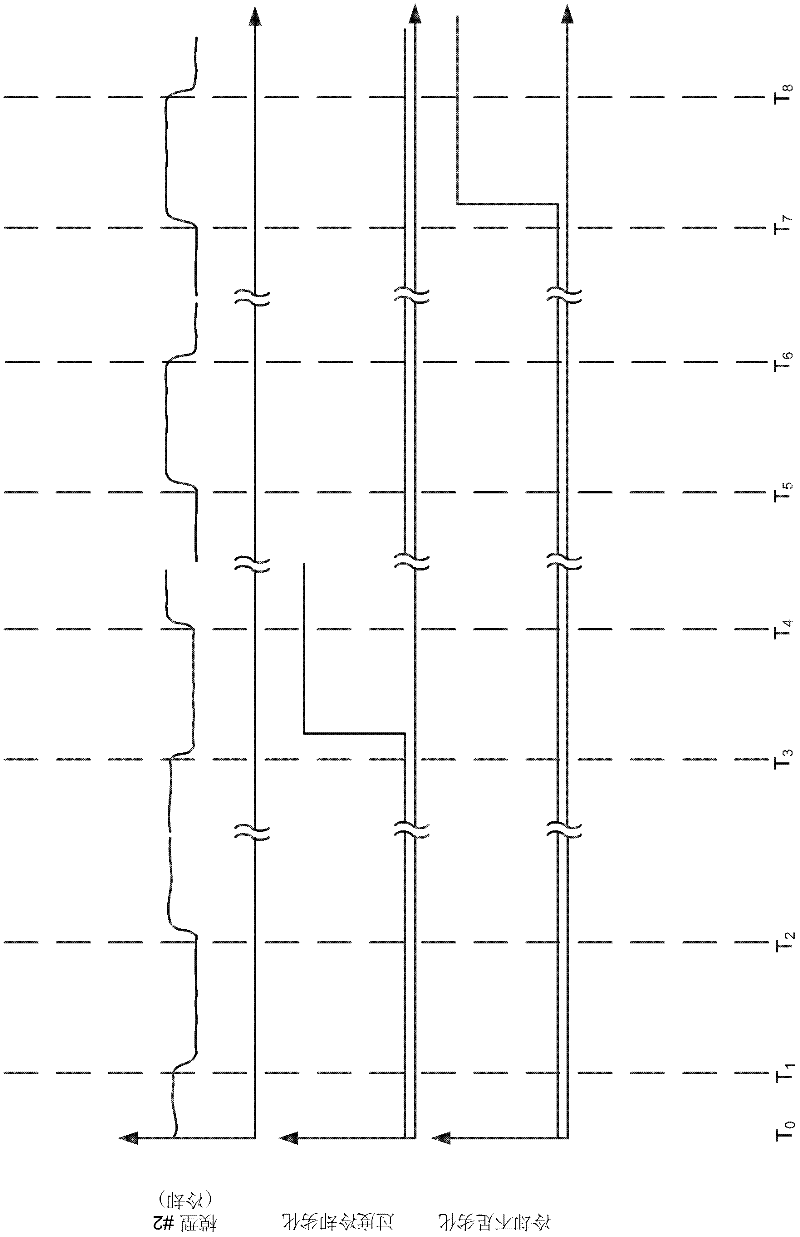

[0024] The present invention relates to monitoring and determining EGR system degradation. In one example, the EGR system is adapted such as figure 1 Diesel engine shown in . However, the present invention may also provide advantages for gasoline and alternative fuel engines. Accordingly, the present invention is not limited to a particular type of engine or a particular EGR system configuration. Figure 2-3 Displays when the engine and EGR system are Figure 4 Analog related signals when the method in run.

[0025] refer to figure 1 , consisting of multiple cylinders ( figure 1 One cylinder of which is shown in ) is controlled by an electronic engine controller 12 . Engine 10 includes combustion chamber 30 and cylinder walls 32 with piston 36 positioned therein and connected to crankshaft 40 . Combustion chamber 30 is shown communicating with intake manifold 44 and exhaust manifold 48 via respective intake valve 52 and exhaust valve 54 . Each intake and exhaust valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com