Pulverized coal burner and boiler

A pulverized coal burner and pulverized coal technology, which is applied in the direction of burners, burners burning powder fuel, burning with various fuels, etc., can solve the problems of high temperature of the burner, slagging of the burner, etc., and achieve the improvement of uneven distribution average effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

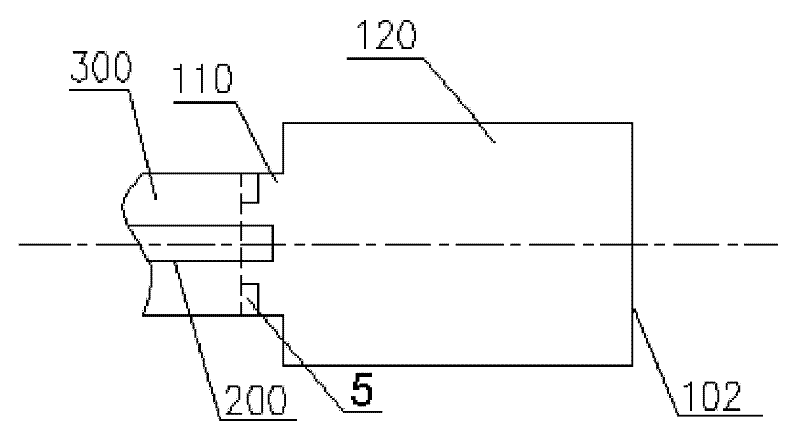

[0042] Please refer to image 3 , which is a schematic structural view of the pulverized coal burner provided in Embodiment 2.

[0043] On the basis of Embodiment 1 of the present invention, the internal combustion chamber 100 of the pulverized coal burner provided by Embodiment 2 includes a main combustion chamber 120 and a deceleration inlet section 110 connected to the front end of the main combustion chamber 120, and the inlet 101 is located at the deceleration inlet section 110 Intersection with the air inlet duct 300.

[0044] A swirl vane 5 may be installed on the inner wall of the deceleration inlet section 110 .

[0045] Such as image 3 As shown, the cross-sectional area of the deceleration inlet section 110 is smaller than the cross-sectional area of the main combustion chamber 120 . When the pulverized coal gas flow enters the main combustion chamber 120 with a large cross-sectional area from the deceleration inlet section 110 with a small cross-sectional ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com