Ground lifting projection screen

A technology of projection screen and floor, which is applied in the direction of optics, instruments, projection devices, etc., can solve the problems of large structure volume, high requirements for support material strength, heavy weight, etc., and achieve the effect of small volume, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

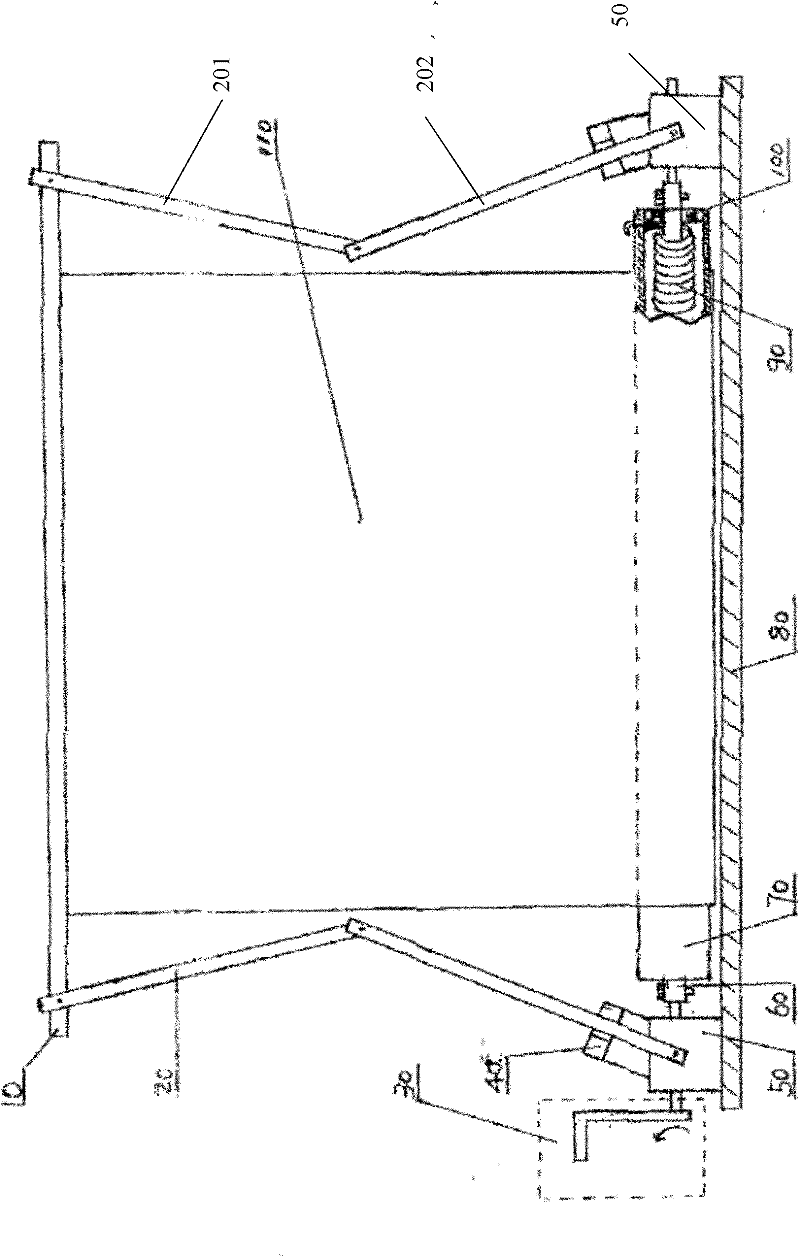

[0027] Such as figure 1 As shown, the floor-mounted projection screen includes a pull rod 10, a foldable bracket 20, a driving force module 30, a limit module 40, a T-shaped steering gear box 50, a synchronization lever 60, a rotating tube 70, a housing 80, a torsion spring 90, Bearing 100, curtain 110.

[0028] There is a rotating tube 70 in the casing 80, and a synchronous rod 60 is arranged in the rotating tube 70. The rotating tube 70 is coaxially supported on the synchronization rod 60 through the bearings 100 at both ends.

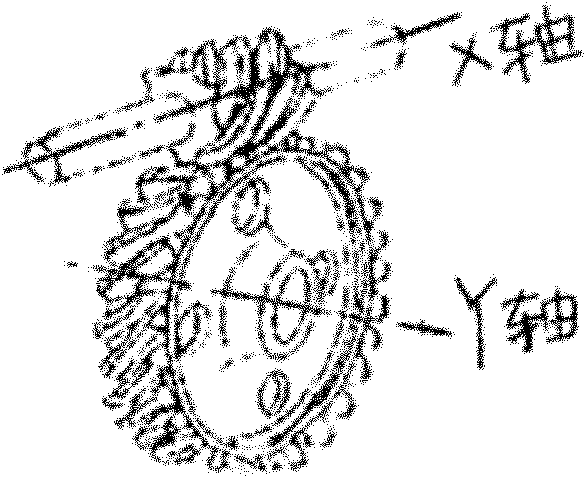

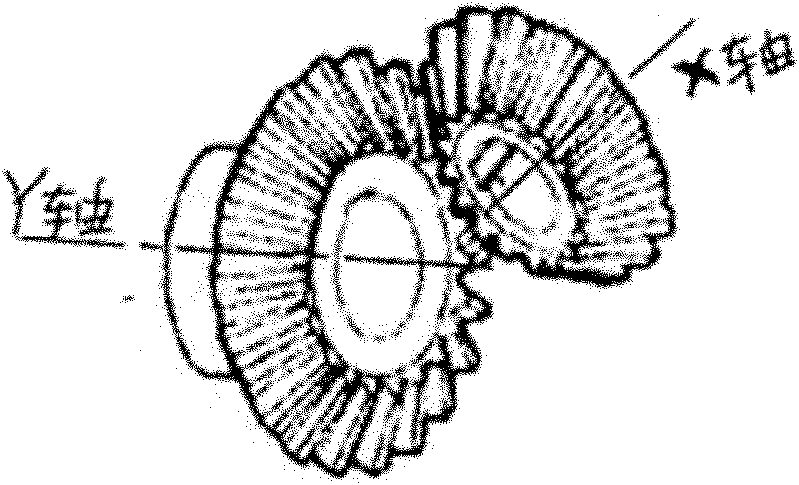

[0029] The two ends of the casing 80 are symmetrically installed with the gear box 50 . Both ends of the synchronization rod 60 are fixedly connected to the X axes of the two gearboxes 50 , so that the X axes of the two gearboxes 50 are synchronized.

[0030] A torsion spring 90 of a certain length is wound around the synchronization rod 60 . One end of the torsion spring 90 is fixed on the synchronization rod 60 , and the other end is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com