Diffusion layer of URFC (unitized regenerative fuel cell) and preparation method thereof

A fuel cell and diffusion layer technology, which is applied to fuel cell components and other directions, can solve the problems of electrode performance degradation, increase in electrode resistance, and increase in dosage, and achieve reduced electrode resistance, adjustable affinity/hydrophobicity, and The effect of improving performance and diffusion mass transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Hydrophobic treatment of the substrate

[0040] Cut 2×2.5cm 2 The carbon paper was dipped in 1wt% PTFE emulsion for several times for hydrophobization treatment, and then fired at 360° C. for 1 hour to obtain the hydrophobization treatment carbon paper.

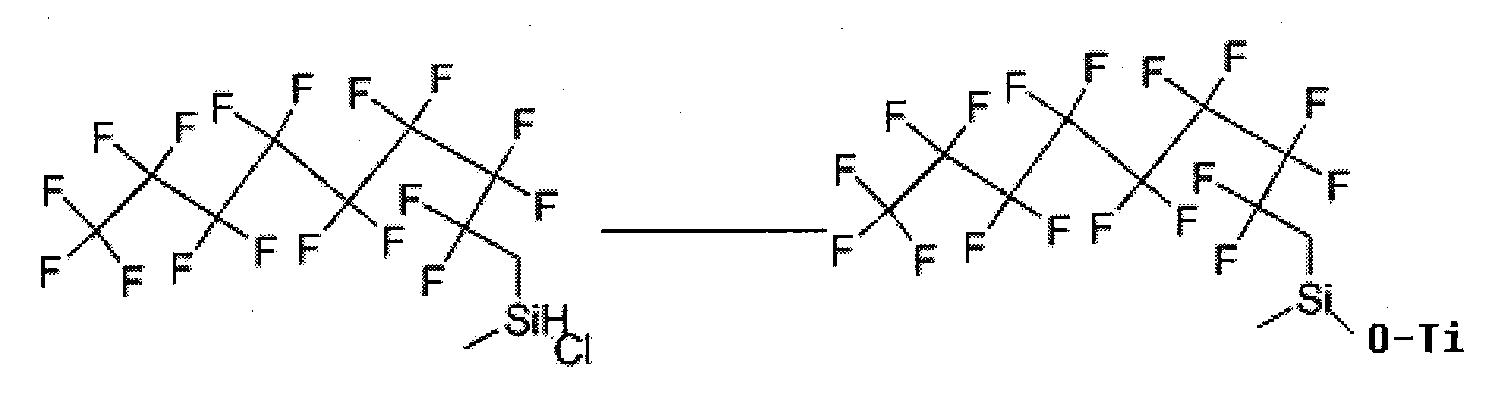

[0041]2) Under a nitrogen atmosphere in a glove box, perfluorooctyldimethylchlorosilane (FDTS) was prepared into a 0.1wt% solution with absolute ethanol, and 50 mg of IrO 2 / Ti catalyst, added to FDTS solution, IrO 2 The mass ratio of / Ti to FDTS is 100:1. The two were stirred at room temperature to cause a condensation reaction, then centrifuged, and dried to obtain pre-hydrophobic treated IrO 2 / Ti leveling layer.

[0042] The prepared pre-hydrophobic treated IrO 2 / Ti leveling layer, add ethanol, mix evenly, add 20mg of PTFE emulsion with a concentration of 20wt%, mix evenly to obtain a leveling layer slurry, and apply the slurry evenly on the carbon paper treated with hydrophobic treatment, and then reheat ...

Embodiment 2

[0053] 1) The hydrophobic treatment of the substrate is the same as in Example 1

[0054] 2) Under a nitrogen atmosphere in a glove box, perfluorooctyldimethylchlorosilane (FDTS) was prepared into a 0.1wt% solution with absolute ethanol, and 50 mg of IrO 2 / Ti catalyst, added to FDTS solution, IrO 2 The mass ratio of / Ti to FDTS is 100:10. The two were stirred at room temperature to cause a condensation reaction, then centrifuged, and dried to obtain pre-hydrophobic treated IrO 2 / Ti leveling layer.

[0055] The prepared pre-hydrophobic treated IrO 2 / Ti leveling layer, add ethanol, mix evenly, add 20mg of PTFE emulsion with a concentration of 20wt%, mix evenly to obtain a leveling layer slurry, and apply the slurry evenly on the carbon paper treated with hydrophobic treatment, and then reheat at 360°C Lower firing for 1 hour to obtain a catalytic leveling layer.

[0056] 3) 4) steps are the same as 3) 4) in embodiment 1.

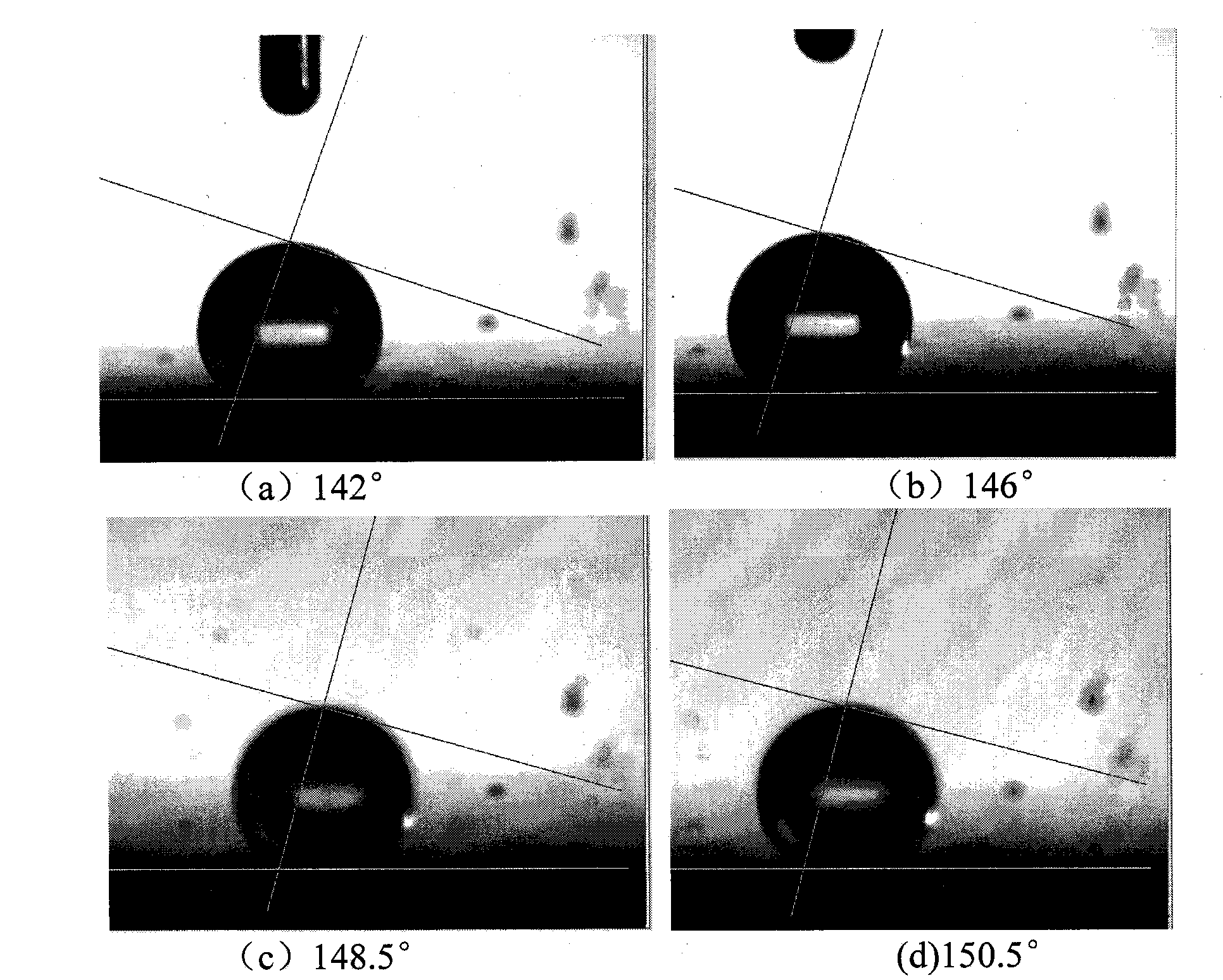

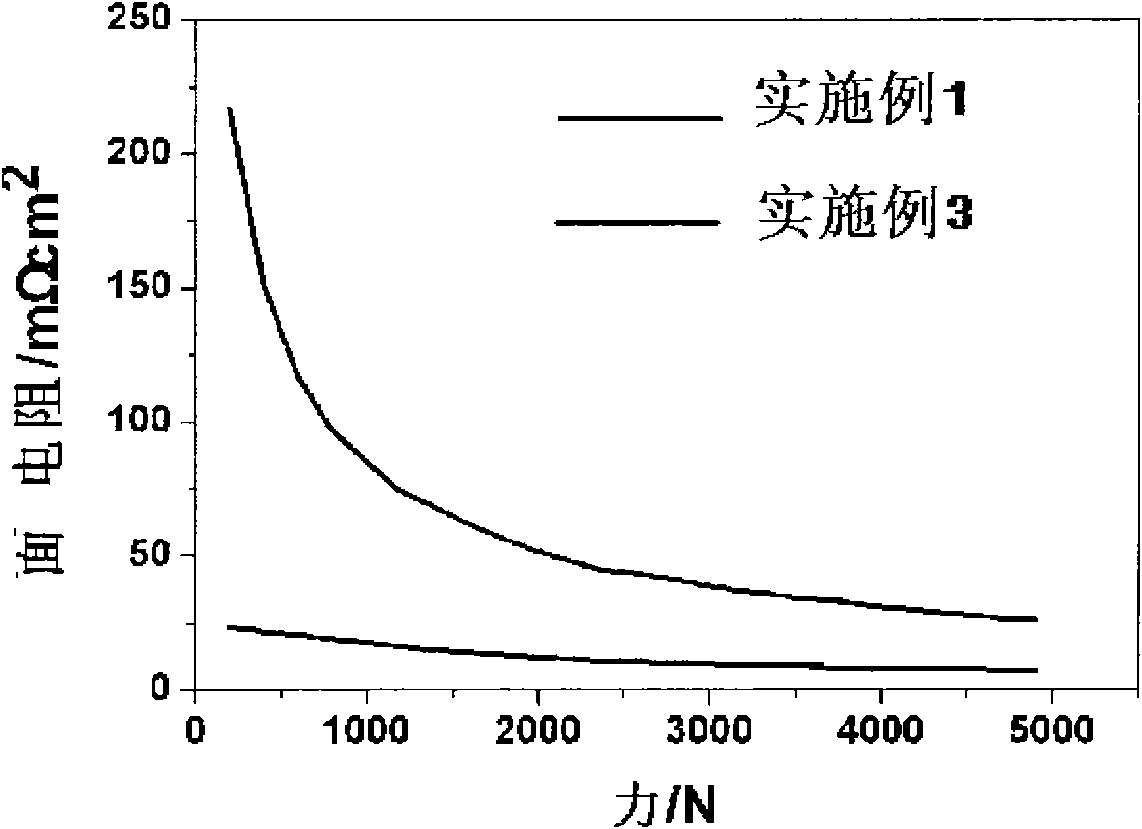

[0057] pass image 3 It can be seen from the s...

Embodiment 3

[0060] 1) The hydrophobic treatment of the substrate is the same as in Example 1

[0061] 2) Under a nitrogen atmosphere in a glove box, perfluorooctyldimethylchlorosilane (FDTS) was prepared into a 0.1wt% solution with absolute ethanol, and 50 mg of IrO 2 / Ti catalyst, added to FDTS solution, IrO 2 The mass ratio of / Ti to FDTS is 100:20. The two were stirred at room temperature to cause a condensation reaction, then centrifuged, and dried to obtain pre-hydrophobic treated IrO 2 / Ti leveling layer.

[0062] The prepared pre-hydrophobic treated IrO 2 / Ti leveling layer, add ethanol, mix evenly, add 20mg of PTFE emulsion with a concentration of 20wt%, mix evenly to obtain a leveling layer slurry, and apply the slurry evenly on the carbon paper treated with hydrophobic treatment, and then reheat at 360°C Lower firing for 1 hour to obtain a catalytic leveling layer.

[0063] 3) 4) steps are the same as 3) 4) in embodiment 1.

[0064] Embodiment 1, 2 and 3 by changing the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com