Fastener

A technology for fasteners and components, applied in the field of fasteners, can solve the problems of the rivet main body 61 and the pin 62 being difficult to engage, fall off, and shake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

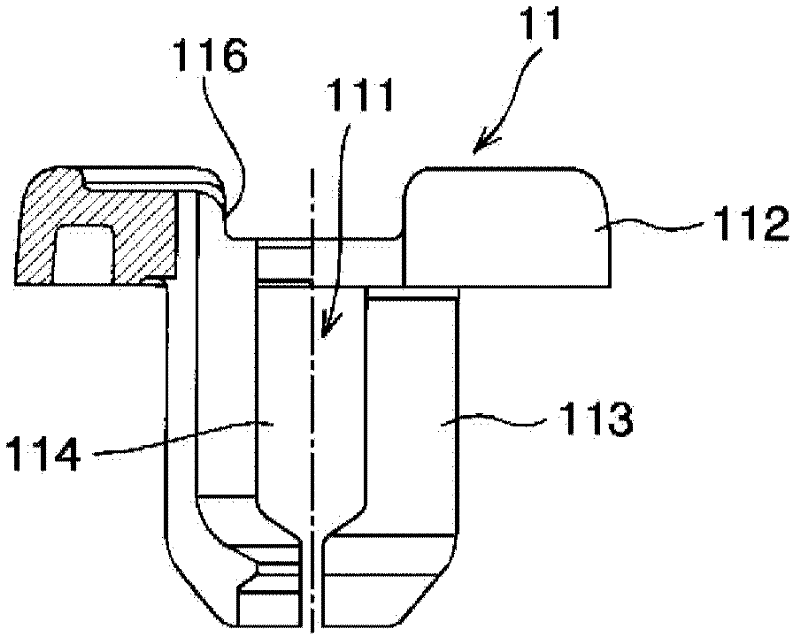

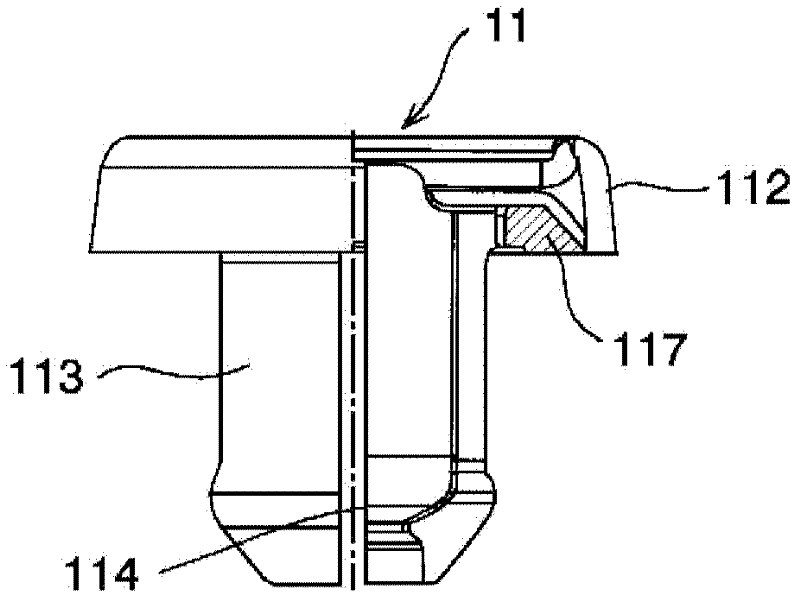

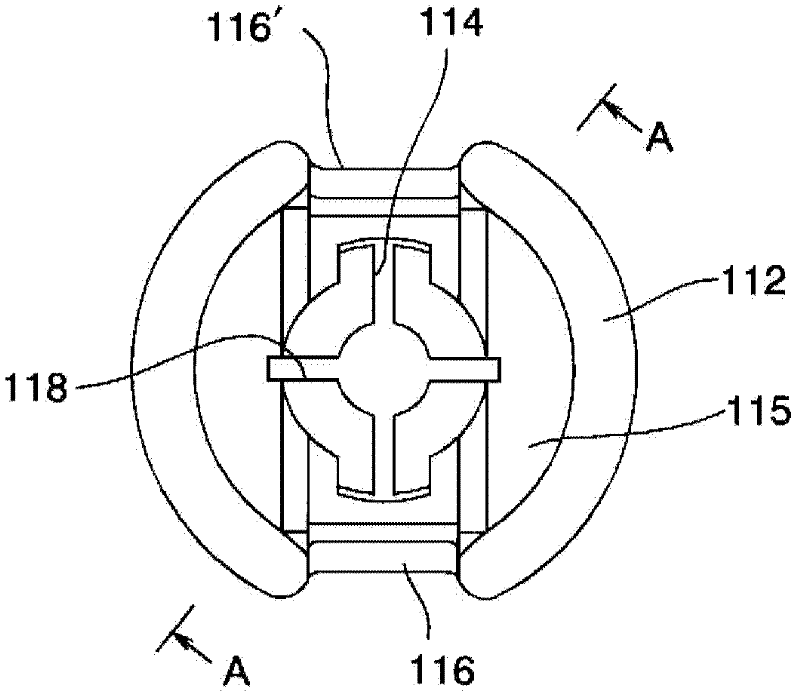

[0032] Hereinafter, the fastener described with reference to the drawings is an example of the embodiment of the present invention. The fastener is inserted into the mounting hole of the mounting member and the mounted member, and is used to fix the two to each other. In more detail, the above-mentioned fastener can be fixedly installed by inserting the male component into the female component mounted in the mounting hole of the mounting component and the mounted component, and using the male component to expand the slotted cylindrical portion placed on the female component. The parts and the mounted parts do not fall off each other. The female member has a flange portion provided with an insertion hole, a cylindrical portion integrally extending downward from the flange portion, and a substantially cross-shaped slit provided in the cylindrical portion. The above-mentioned slit formed in the shape of a cross groove is inserted into the foot and sliding protrusions described lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com