Plasma display panel drive method and plasma display device

A technology for display panels and driving methods, applied to static indicators, parts of color TVs, parts of TV systems, etc., capable of solving problems such as long discharge delay time, inability to absorb deviations in discharge characteristics, unstable writing operations, etc. problem, to achieve the effect of improving contrast, stabilizing writing action, and widening the setting boundary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

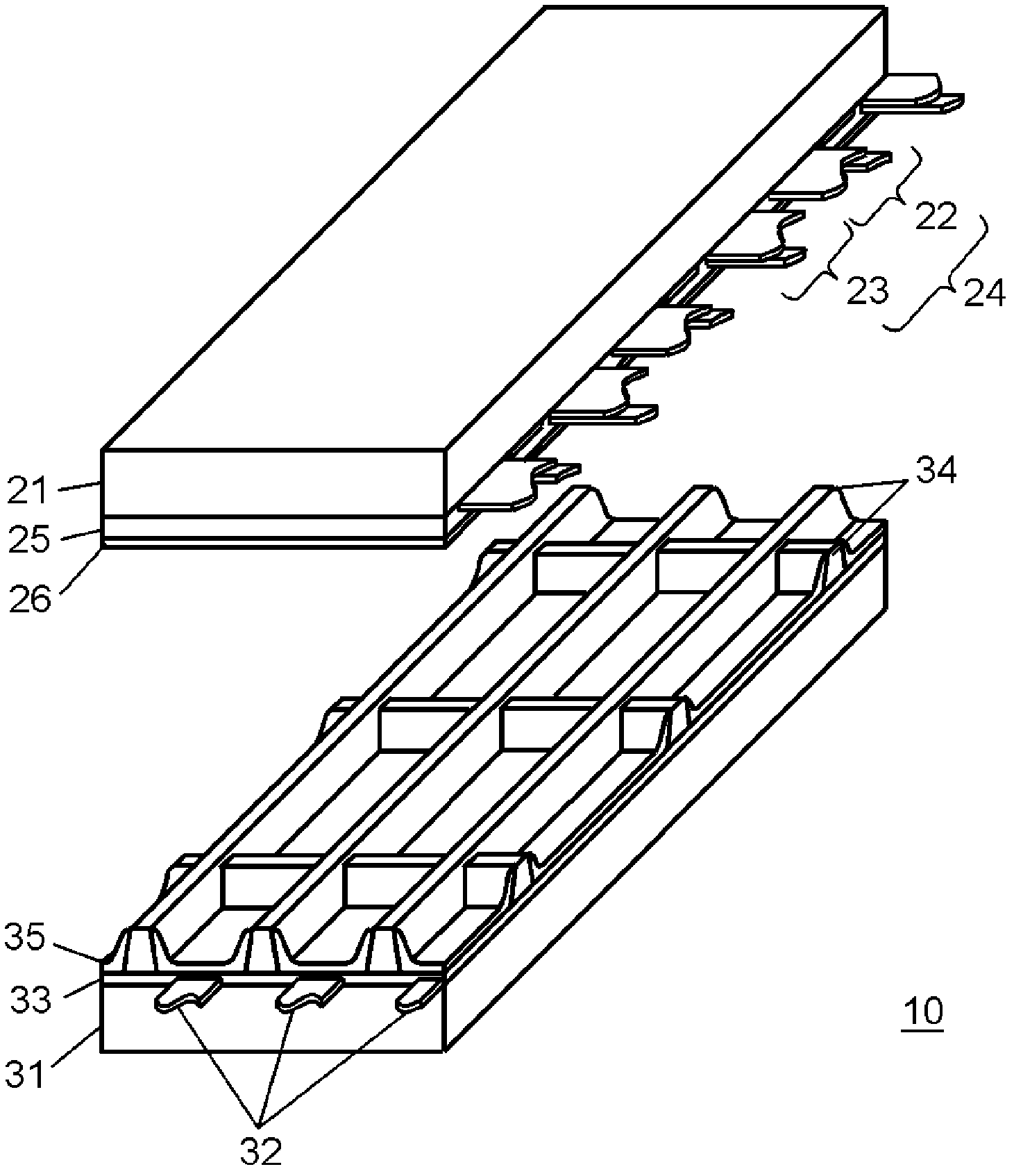

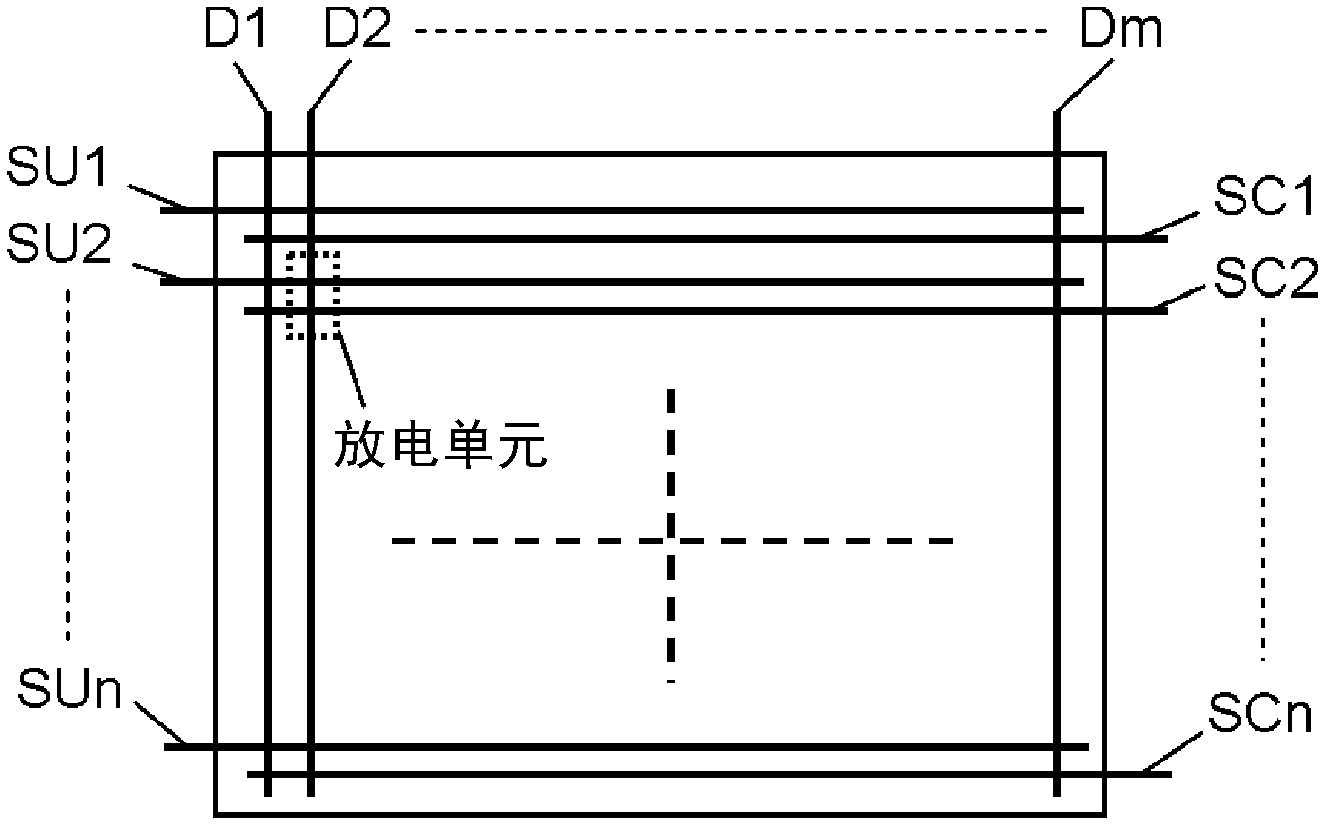

[0032]figure 1 It is an exploded perspective view of panel 10 used in the plasma display device according to Embodiment 1 of the present invention. A plurality of display electrode pairs 24 including scan electrodes 22 and sustain electrodes 23 are formed on front substrate 21 made of glass. Furthermore, a dielectric layer 25 is formed to cover the display electrode pairs 24 , and a protective layer 26 is formed on the dielectric layer 25 . The protective layer 26 is formed of magnesium oxide, which is a material with high electron emission performance, in order to facilitate discharge. A plurality of data electrodes 32 are formed on rear substrate 31 , and dielectric layer 33 is formed so as to cover data electrodes 32 , and grid-shaped barrier ribs 34 are further formed thereon. Phosphor layers 35 that emit light in respective colors of red, green, and blue are provided on the side surfaces of the barrier ribs 34 and the dielectric layer 33 . As a red phosphor, for example...

Embodiment approach 2

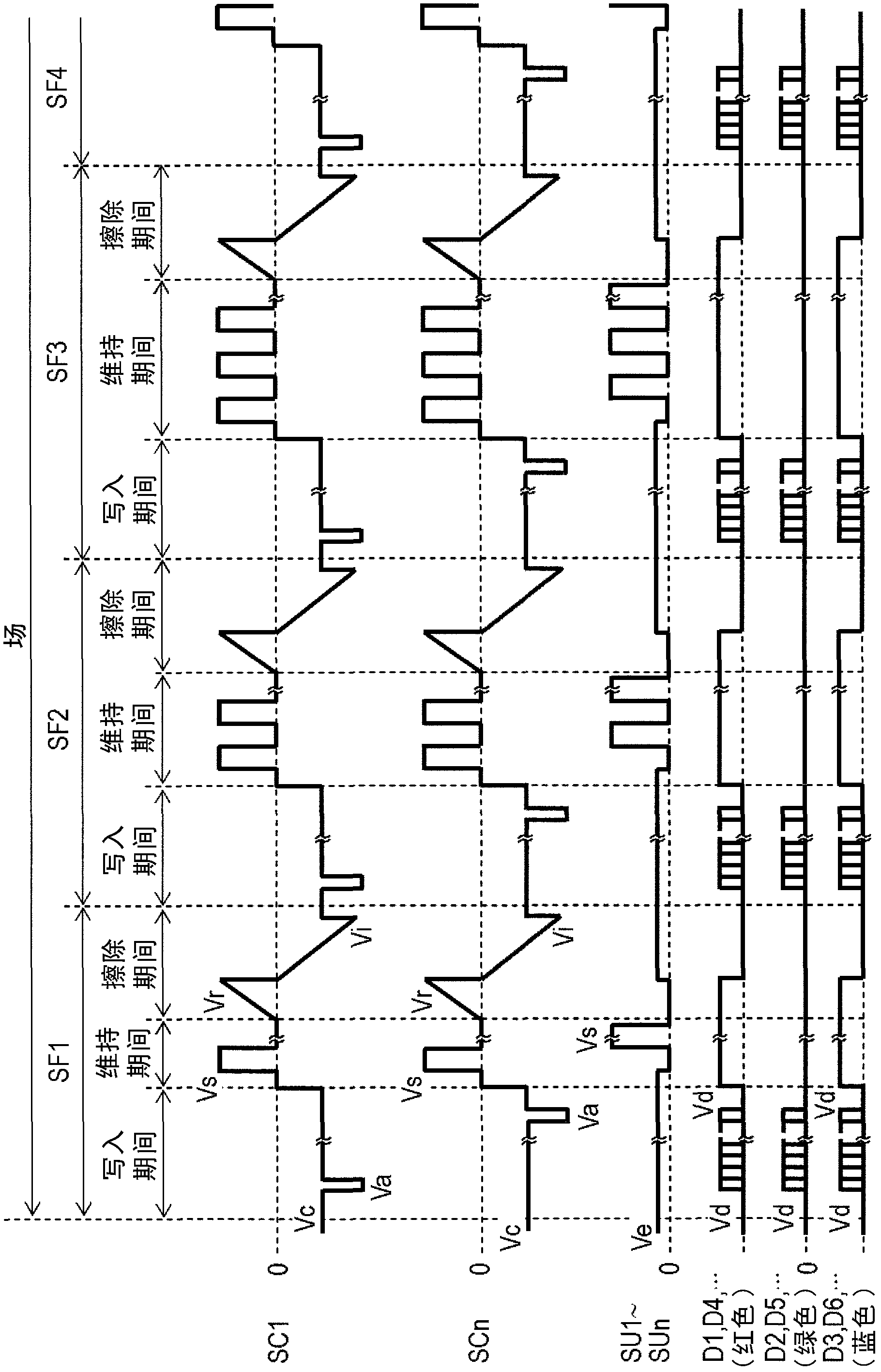

[0099] Hereinafter, other driving voltage waveforms of the present invention will be described using the drawings. Figure 10 as well as Figure 11 It is a driving voltage waveform chart applied to each electrode of the plasma display device in the second embodiment of the present invention, Figure 10 represents the driving voltage waveform in field 1, Figure 11 shows the driving voltage waveform in the second field. Furthermore, in (Embodiment 2), the panel is driven using the first field and the second field alternately. Also in this embodiment, the same subfield configuration as in (Embodiment 1) is used to drive the same panel 10 as in (Embodiment 1).

[0100] In the address period of SF1 in the first field, voltage 0 (V) is applied to data electrode D1 through data electrode Dm, voltage Ve is applied to sustain electrode SU1 through sustain electrode SUn, and voltage Vc is applied to scan electrode SC1 through scan electrode SCn. . Next, a scan pulse of voltage Va ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com