Bolt-fixture-free impact plate of impact crusher

A technology of impact crusher and impact plate, applied in the field of machinery, can solve the problems that the impact surface cannot meet the demand of materials, the crushed materials are easy to appear flakes, and the impact plate fails, so as to improve the quality and output, and increase the utilization rate. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

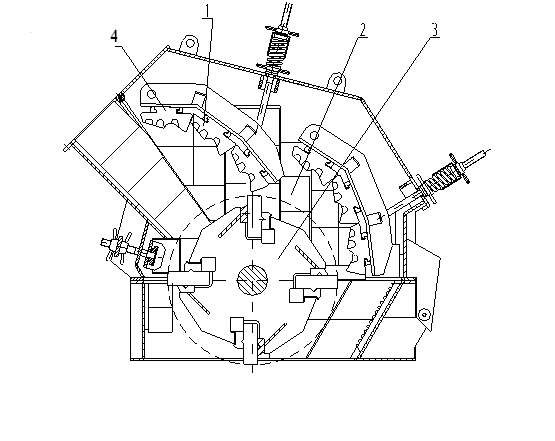

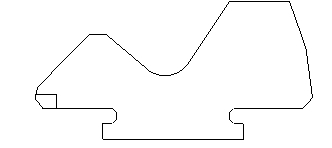

[0022] Such as figure 1 As shown, the impact crusher uses the blow bar on the high-speed rotating rotor 3 to produce high-speed impact on the materials fed into the crusher chamber 2 for crushing, and the crushed materials are thrown to the other side of the crushing chamber at high speed along the tangential direction. The impact plate 1 at one end is broken again, and then rebounds from the impact plate 1 to the blow bar, and continues to repeat the above process. Due to the impact of the blow bar on the material, the impact with the impact plate and the collision between the materials, the material is continuously produced. Cracks, loose and shattered. The impact plate disclosed in the present invention is installed at one end of the crushing cavity 2 of the impact crusher, the fixing device 4 of the impact plate 1 is installed on the non-working surface, and the fixing device 4 of the impact plate protrudes outward , so that the middle part of the counterattack plate is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com