Tool for fastening pipeline flange bolts

A technology for fastening tools and pipeline flanges, which is applied in the field of auxiliary tools for pipeline connection, can solve problems such as high cost of use, leakage of pipeline flanges, and low work efficiency, so as to prolong the sealing cycle, avoid leakage problems, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

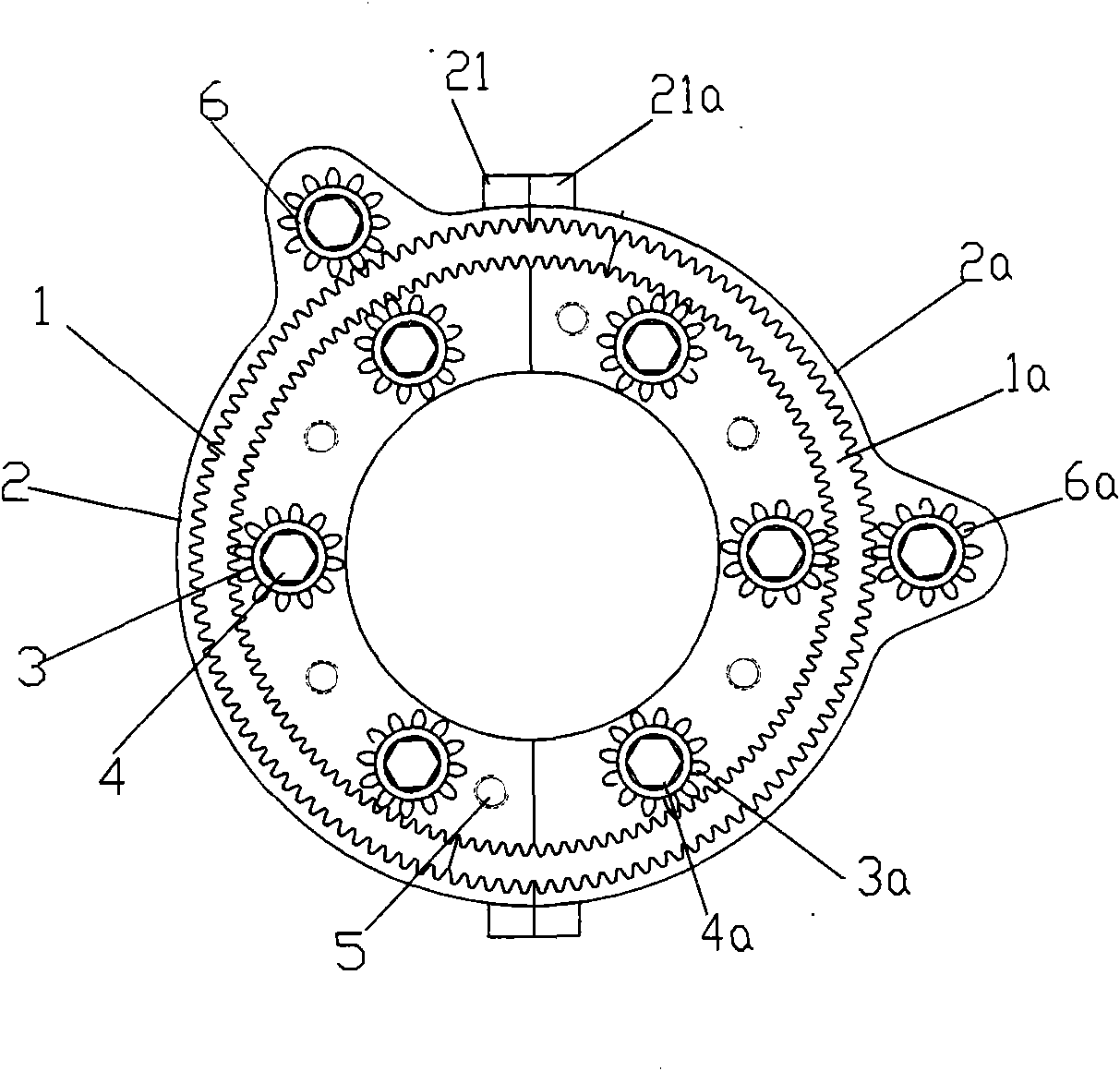

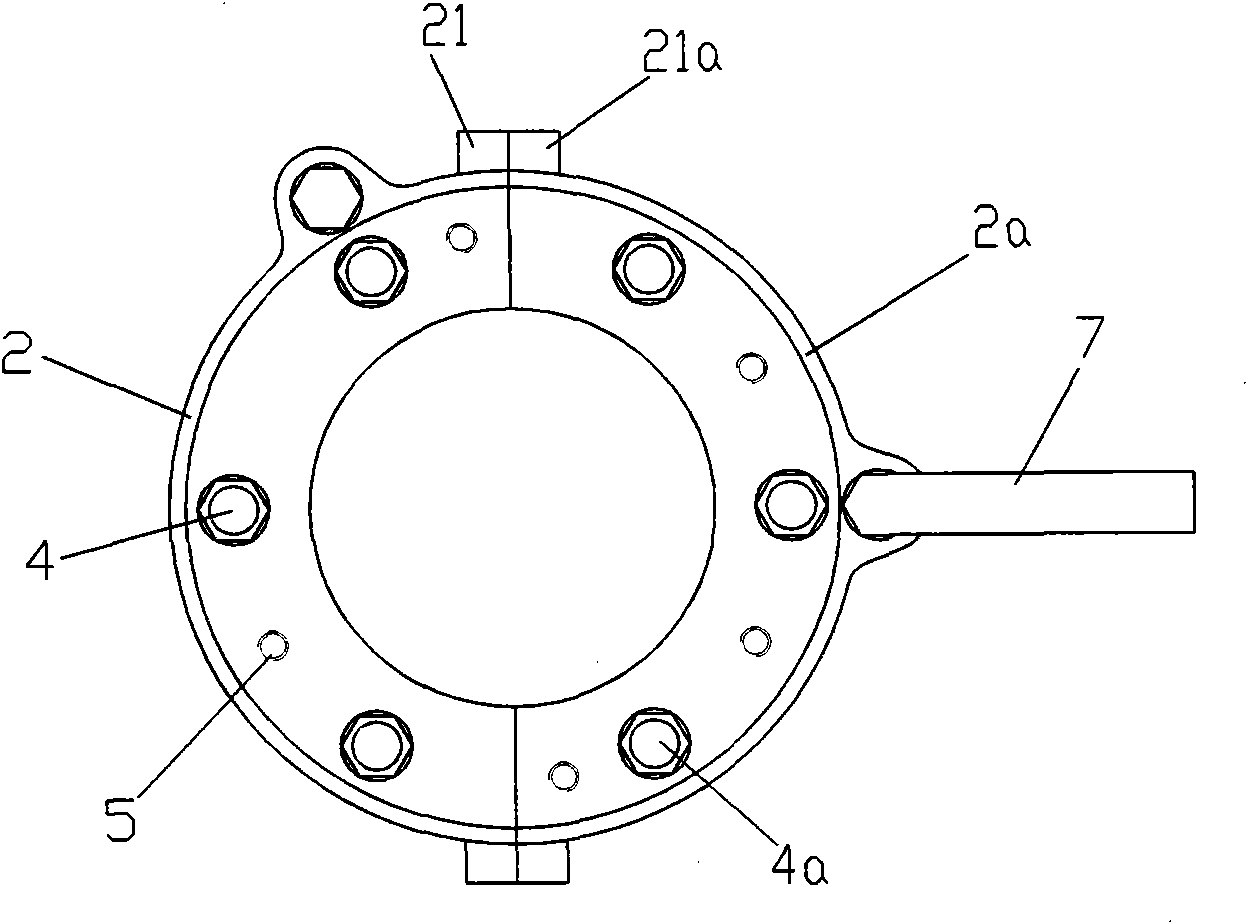

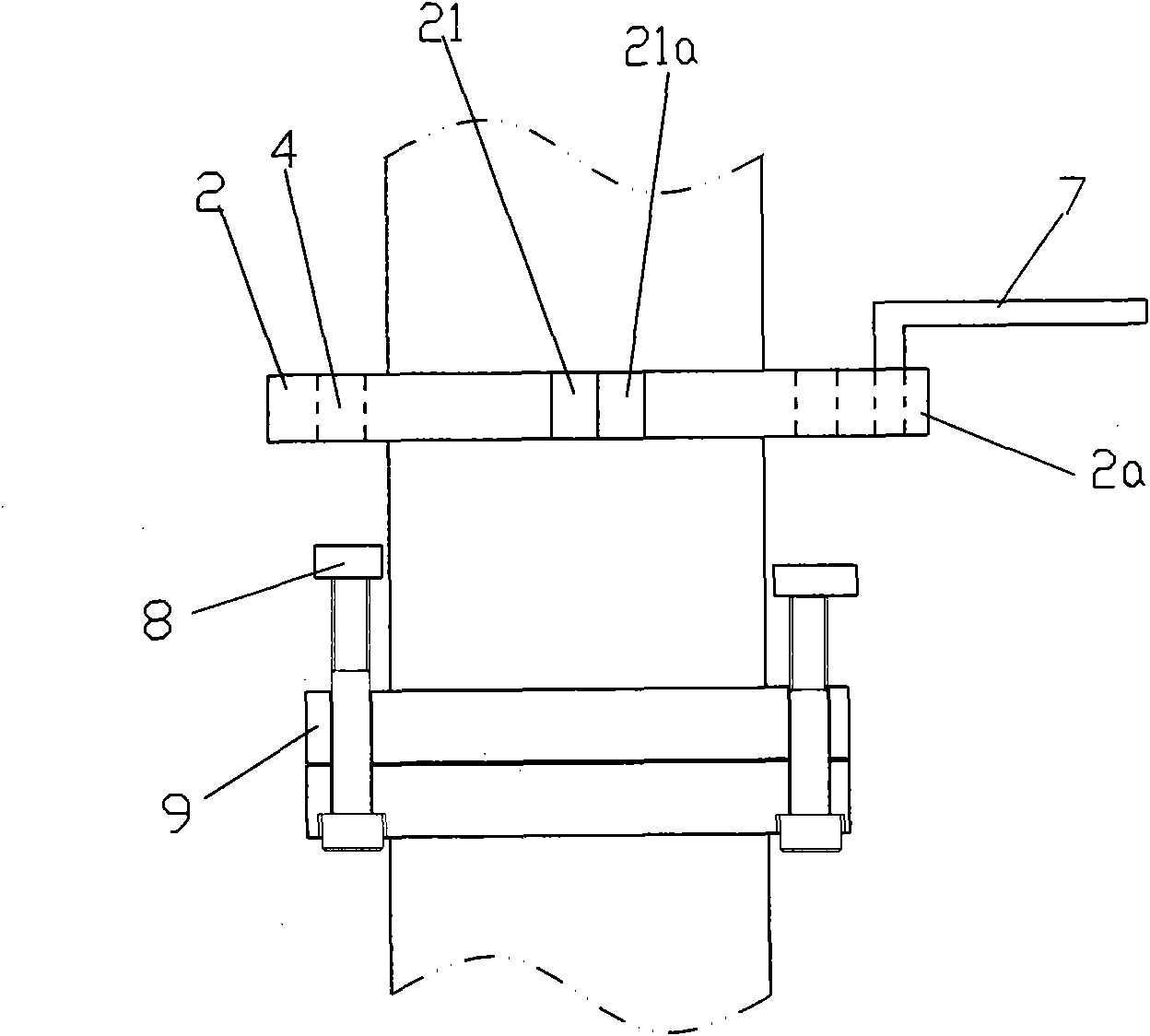

[0020] figure 1 It is a schematic diagram of the internal structure of the present invention, figure 2 It is a schematic structural view of the present invention, as shown in the figure, the pipeline flange bolt fastening tool of the present embodiment includes two half-ring shells that are fixedly connected to form a full circle shell in a detachable manner (half-ring shells in the figure Housing 2 and half-ring housing 2a), said half-ring housing 2 and half-ring housing 2a are respectively provided with a drive assembly, said drive assembly includes a sleeve gear 3, a half-ring rack 1 and a drive gear 6; The half-ring rack 1 is arranged in the half-ring rack groove formed in the half-ring housing 2, the sleeve gear 3 and the driving gear are both engaged with the half-ring rack 1, and the sleeve gear 3 is connected to the standard flange The bolt holes are distributed in the semi-annular rack groove in the same form, and the sleeve gear 3 is fixedly fitted with the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com