Electrolytic tank structure for preventing upwarp of tank shell during the start-up period of electrolytic tank

An electrolytic cell and cell shell technology, applied in the field of electrolytic cell structure, can solve the problems affecting the service life of the lining, deformation of the lining of the electrolytic cell, uneven distribution of cathode current, etc., so as to solve the uneven distribution of cathode current, improve the service life, The effect of solving inner lining damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

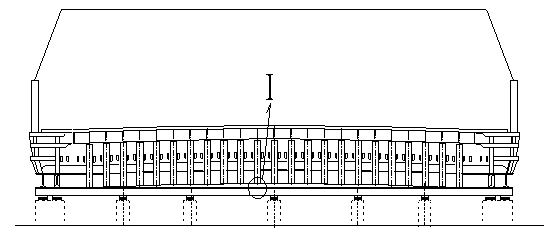

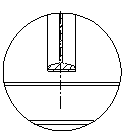

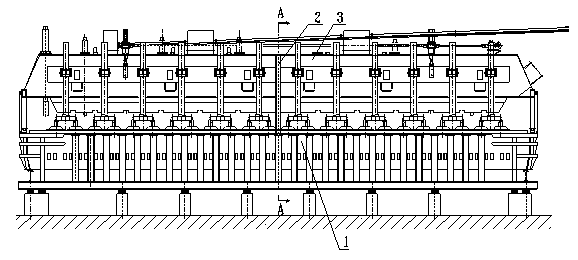

[0019] Embodiment of the present invention: two temporary supports 2 are arranged in the middle of the electrolytic tank and on both sides of the large surface.

[0020] The upper end of the temporary support 2 is pushed against the upper edge of the superstructure girder 3 , and the lower end is pushed against the inner side of the edge of the tank shell 1 .

[0021] Alternatively, the upper end of the temporary support 2 is pushed against the lower edge of the superstructure girder 3 , and the lower end is pushed against the inner side of the edge of the tank shell 1 .

[0022] An insulation board is arranged between the upper end of the temporary support 2 and the upper structural girder 3 , and between the lower end and the tank shell 1 .

[0023] For the case where the upper end of the temporary support 2 is pushed against the upper edge of the superstructure girder 3: the upper end should be pushed against the upper edge of the superstructure girder 3 from the outside to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com