An automatic feeding trough for calf pellet feed

A pellet feed and automatic technology, which is applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of waste, easy to be affected by moisture, mildew and deterioration, and calves are prone to diarrhea, etc., and achieve the effect of convenient use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

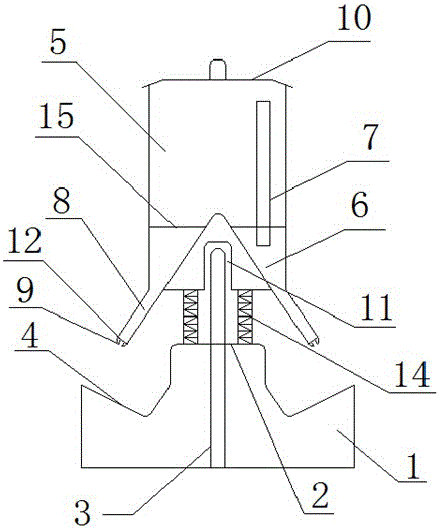

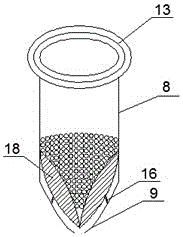

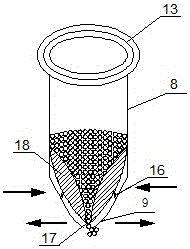

[0020] Such as Figure 1-4 As shown, the present invention discloses an automatic trough for calf pellet feed, and its technical scheme is: the automatic feed trough for calf pellet feed mainly includes a collection tray 1, a circular raised support body 2, and a connecting rod 3 , feeding position 4, storage box 5, conical feed diverter 6, monitoring port 7, circular discharge port 8, sucker 9, storage box cover 10, circular deep hole 11, wedge-shaped feed flow block device 12, thread 13, spring 14, feed deflector 15 and hard spacer 16, the top of described storage box 5 is provided with storage box cover 10, pellet feed is placed in the storage box 5, cover The upper storage box cover 10, the storage box cover 10 prevents the pellet feed from being exposed to the air, effectively prevents the pellet feed from being damp and moldy, and the wall of the storage box 5 is provided with a monitoring port 7, which can be observed at any time The amount of feed in the storage box 5...

Embodiment 2

[0024] On the basis of Embodiment 1, the sucker 9 made of rubber and the collecting pan 1 are at an angle of 60°, so that it is relatively gentle on the whole, so that the circular discharge port 8, the sucker 9 and the wedge-shaped feed The force-bearing body of the piled feed between the flow blockers 12 is not entirely the wedge-shaped feed flow blocker 12, which effectively reduces the bearing capacity of the feed flow blocker 12, and makes the feed in the storage box 5 work without calves. It does not flow out when sucking, which effectively prevents the waste of feed flowing out due to its own gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com