BIM-based large steel structure rotating slope reverse construction method

A construction method and steel structure technology, applied in the direction of ramps, stepped structures, building structures, etc., can solve the problems of many components, difficult installation, and high height, and achieve the goals of reducing construction difficulty, saving construction costs, and shortening the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

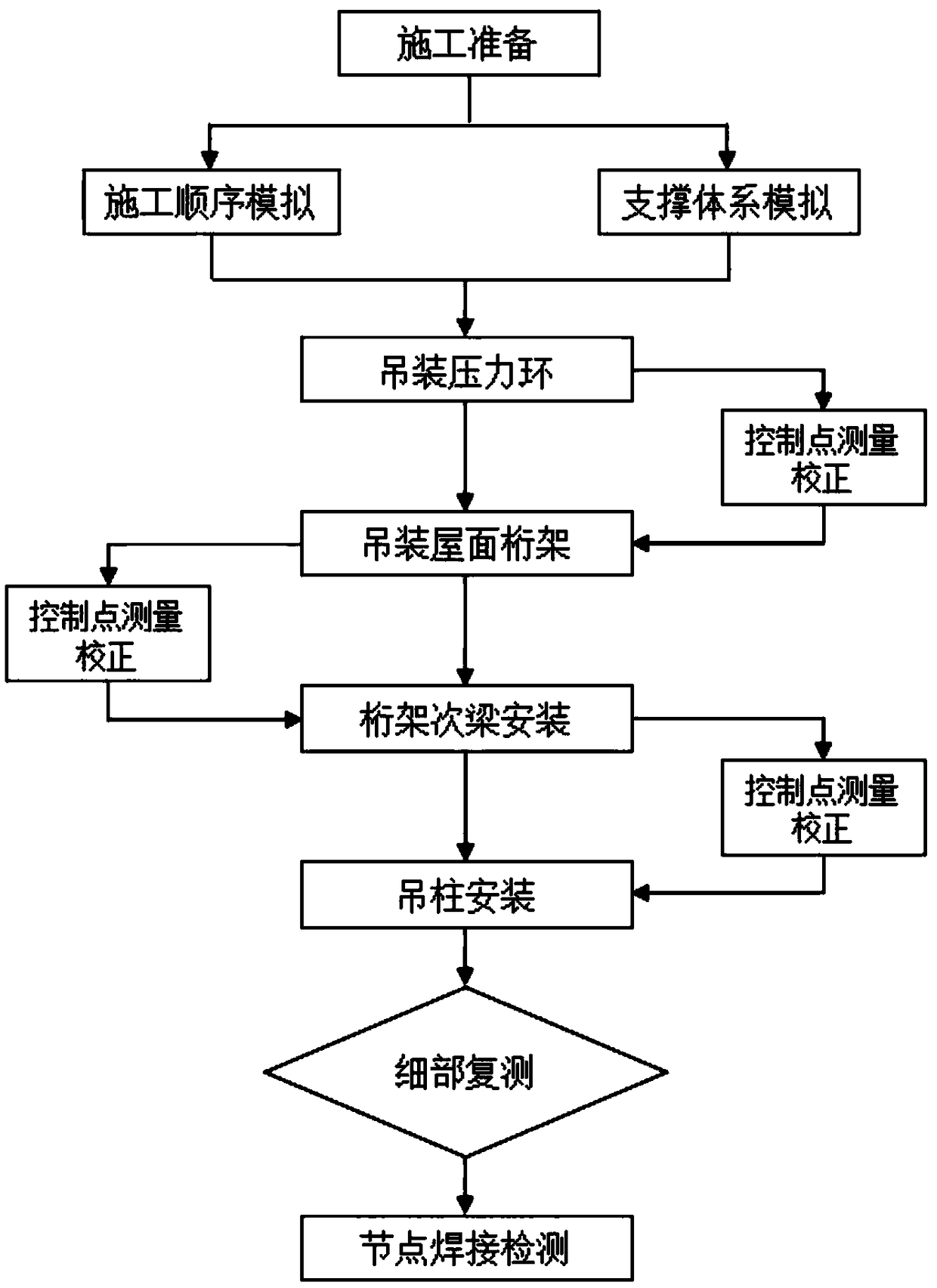

[0043] Such as figure 1 The shown is a BIM-based flip-chip construction method for large-scale steel structure rotary ramps, which is suitable for the installation and construction of various complex steel structure rotary ramps. The "flip-chip method" is used to start installation from the top of the building and end at the bottom of the building , including the following steps:

[0044] 1. Construction preparation

[0045] (1) Establish a BIM model, determine the installation sequence of the rods, use software to establish a refined data model in the computer, and then use the method of reverse simulation to simulate the entire construction process, determine the installation sequence of the rods and number all the components;

[0046] (2) Assemble the upper and lower chords of the truss into a complete truss on the ground, and at the same time assemble the central pressure ring of the rotating ramp. After the two parts are assembled, they will be corrected, and the compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com