A device and method for high-speed queuing out seeds with cone vibration

A cone and high-speed technology, which is applied in the field of cone vibration and high-speed queuing and seeding devices, can solve the problems of high manufacturing precision, inability to break the arch by itself, and high overlapping rate of seed particles, so as to reduce the cost of parts manufacturing and maintenance, and daily operation It is convenient for maintenance and cleaning, and reduces the chance of arching and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

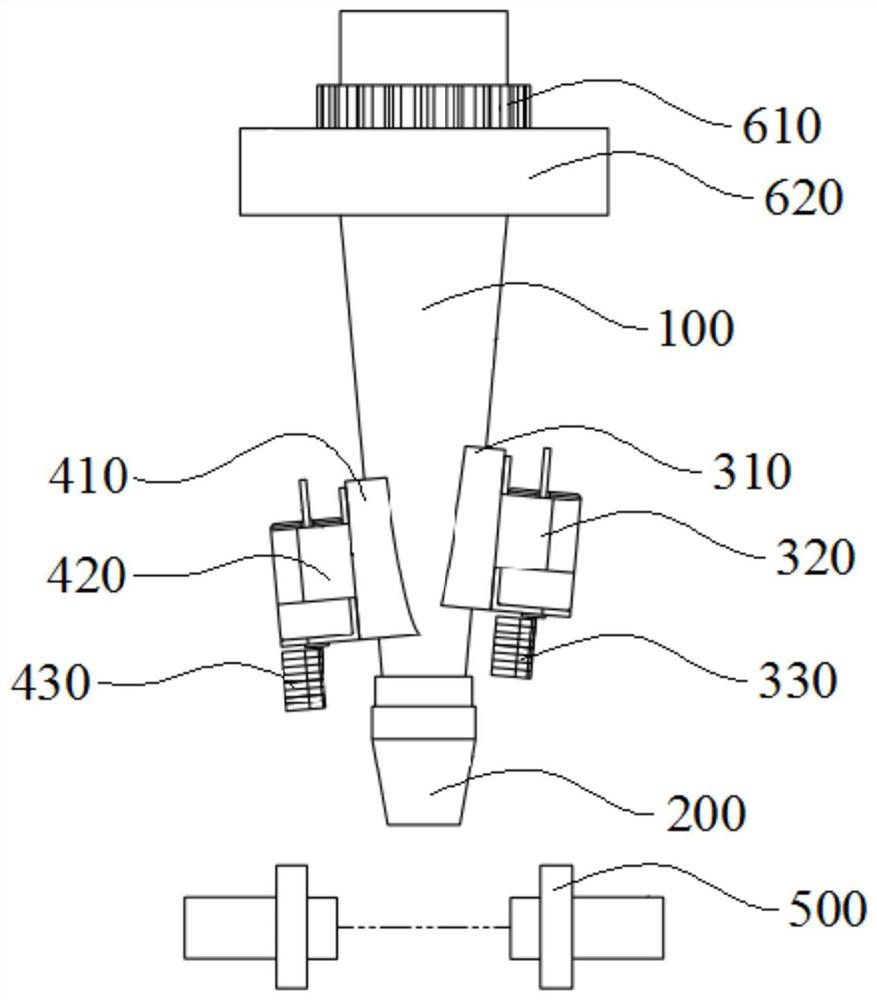

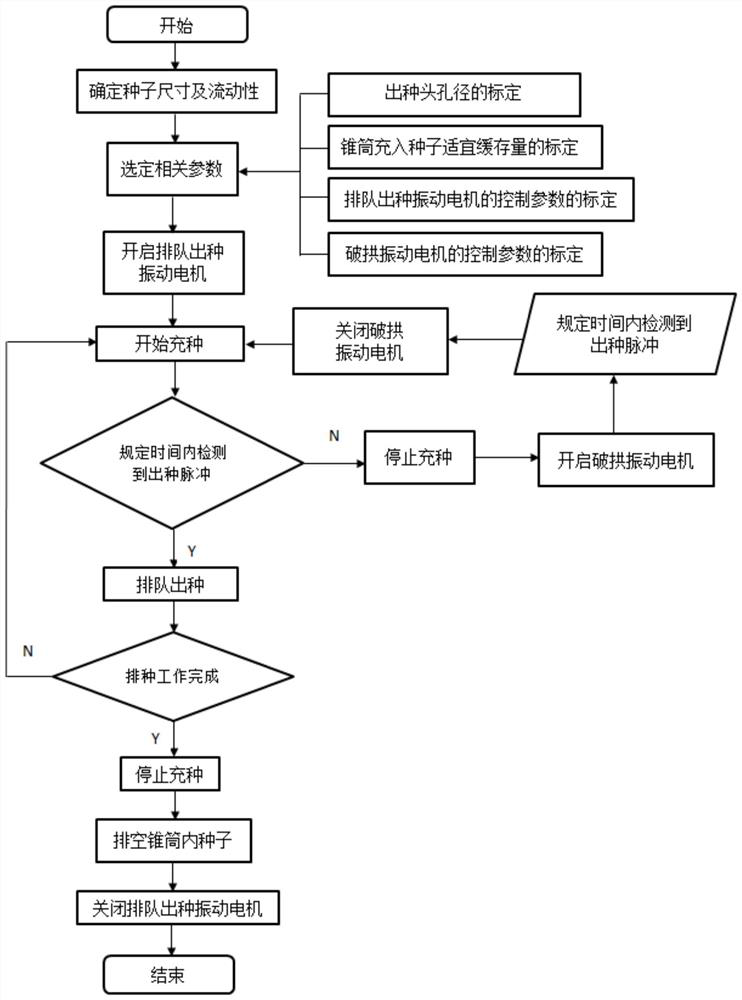

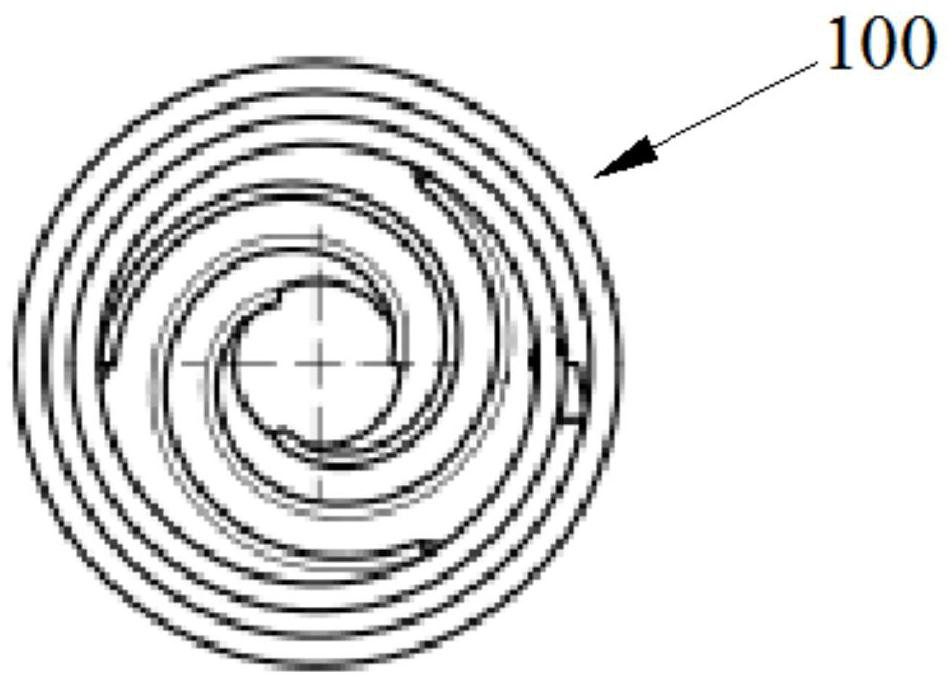

[0065] like figure 1 As shown in the figure, a high-speed queuing-out device for cone-cylinder vibration in this embodiment includes a cone-cylinder 100, a seed-feeding head 200, a queuing-feeding vibration motor unit 420, an arch-breaking vibration motor unit 320, eccentric blocks 330, 430, Vibration isolation member 620 , clamping nut 610 , mounting plates 310 , 410 , and arch detection system 500 . The vibration isolation member 620 is fixed on the upper end of the cone 100 by the clamping nut 610; the seeding head 200 is installed on the lower end of the cone 100; The device adopts the way of cone vibration, high displacement control accuracy, simple structure, good seeding uniformity and low seed damage rate; and a single cone can be used to achieve high-speed queuing and seeding, and the volume is small, which makes daily operation and maintenance. It is more convenient to clean up, especially suitable for drones with limited load capacity.

[0066] In the above-descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com