Double-glass-fiber covered enamelled copper flat wire and production process thereof

A technology of double glass fiber wrapping and production process, applied in the direction of flat/ribbon cable, bendable conductor, cable/conductor manufacturing, etc., can solve the problems of shortening service life, cracking of insulation layer, coil damage, etc., to avoid bending cracking , prolong the service life, improve the effect of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

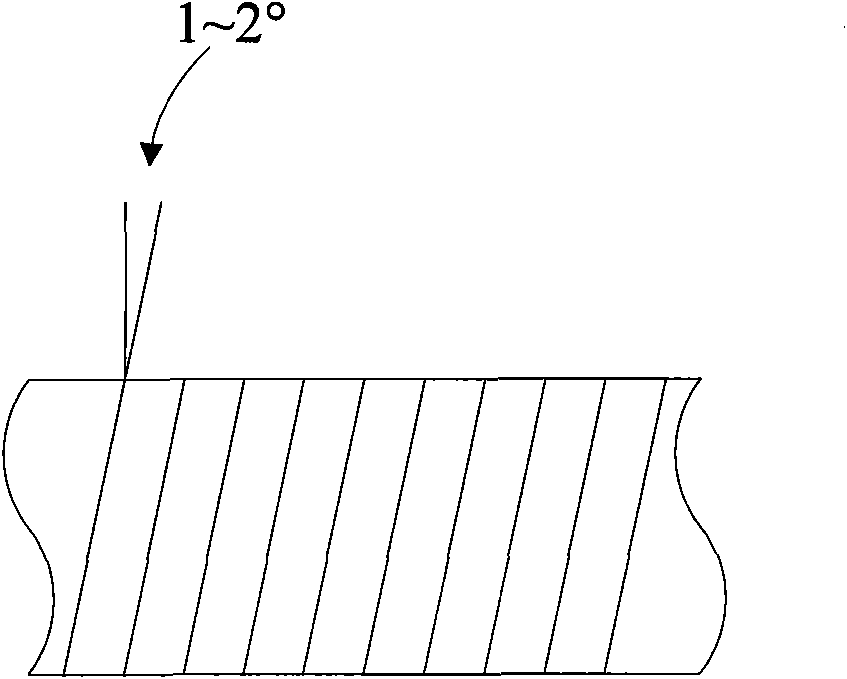

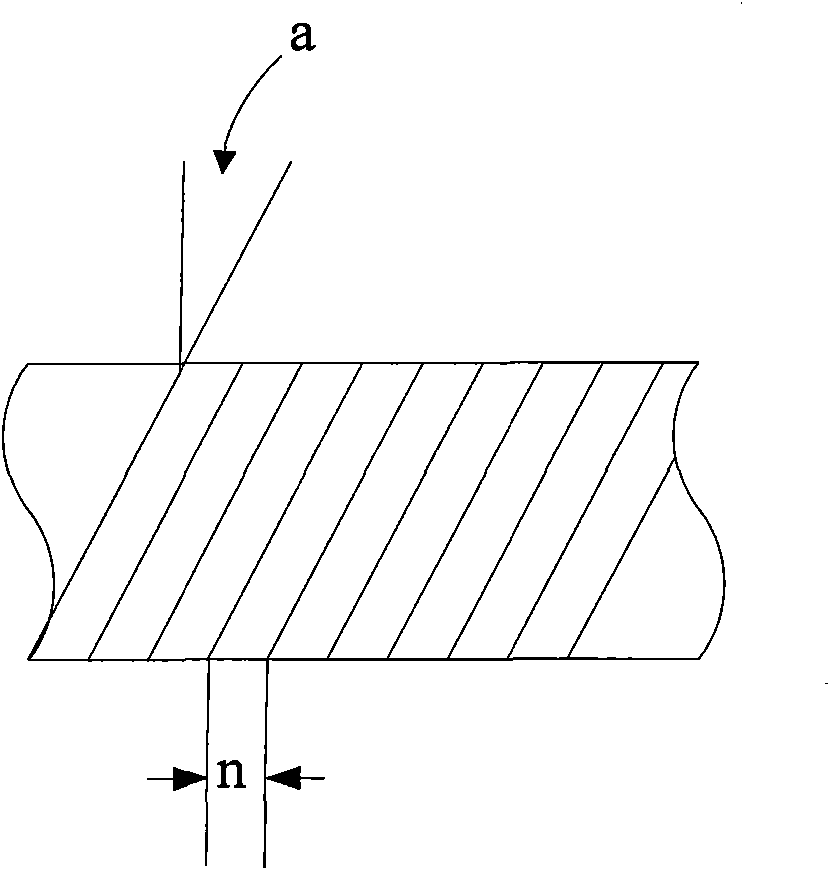

[0013] like figure 1 As shown, in the prior art, a wrapping angle of 1-2° is adopted, so that when the coil is wound, especially the glass filament at the bending part will reduce the adhesion performance due to bending cracks. like figure 2 As shown, the present invention adopts a mesh glass fiber layer whose winding pitch n is more than 5 millimeters and less than 6 millimeters, and the winding angle a is greater than 10° and less than 30°, so that the phenomenon of bending and cracking of the winding wire when winding the coil can be avoided. And ensure that the glass wire is close to the copper flat wire, especially can improve the adhesion of the bending part of the copper flat wire.

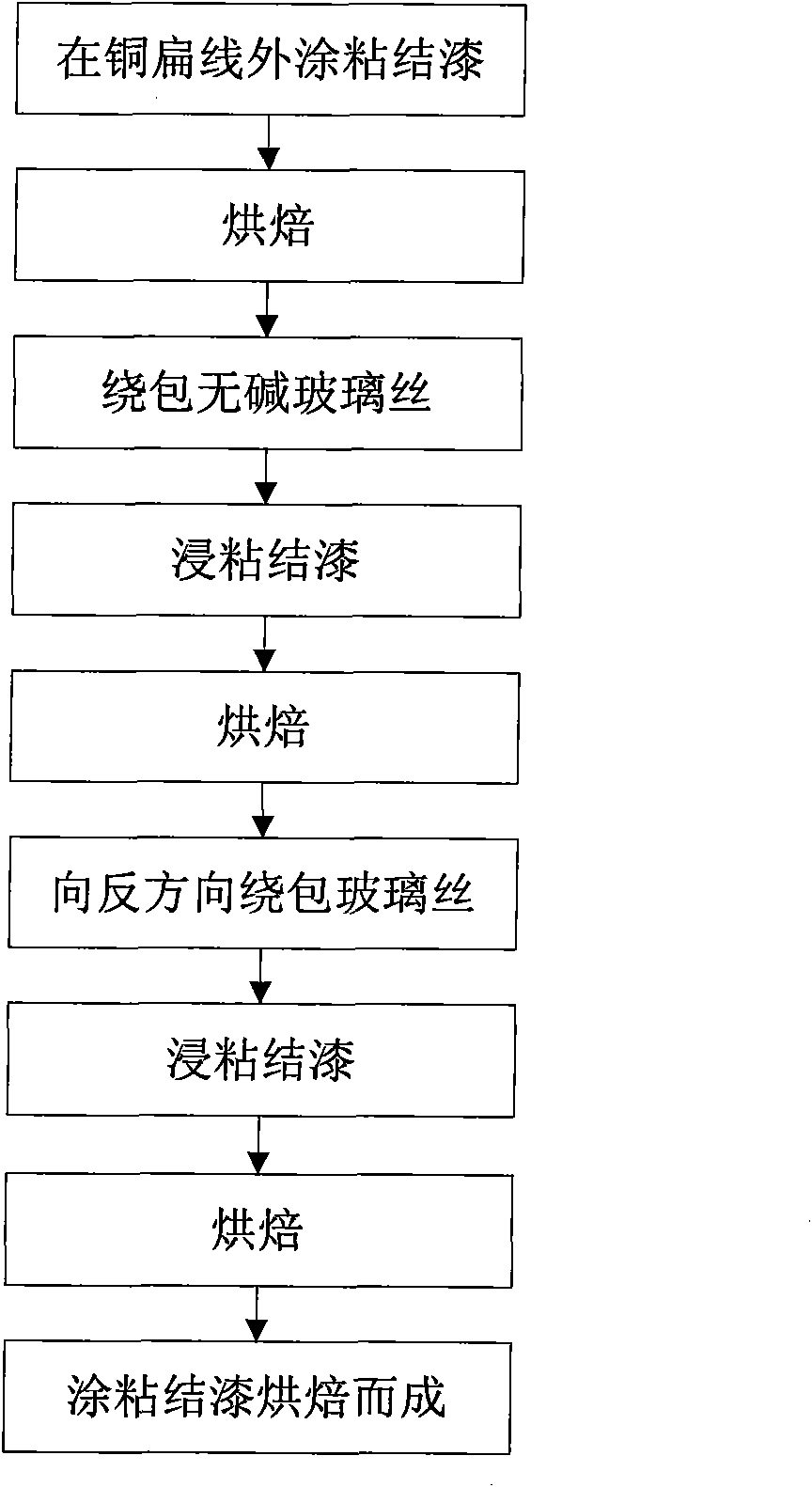

[0014] like image 3 Shown, the production technology of double glass fiber clad copper flat w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com