Printed circuit board, tinning line thereof and tinning method thereof

A printed circuit board and circuit technology, applied in the field of microelectronics, can solve problems such as large heat generation, uneven tinning, and circuit burnout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

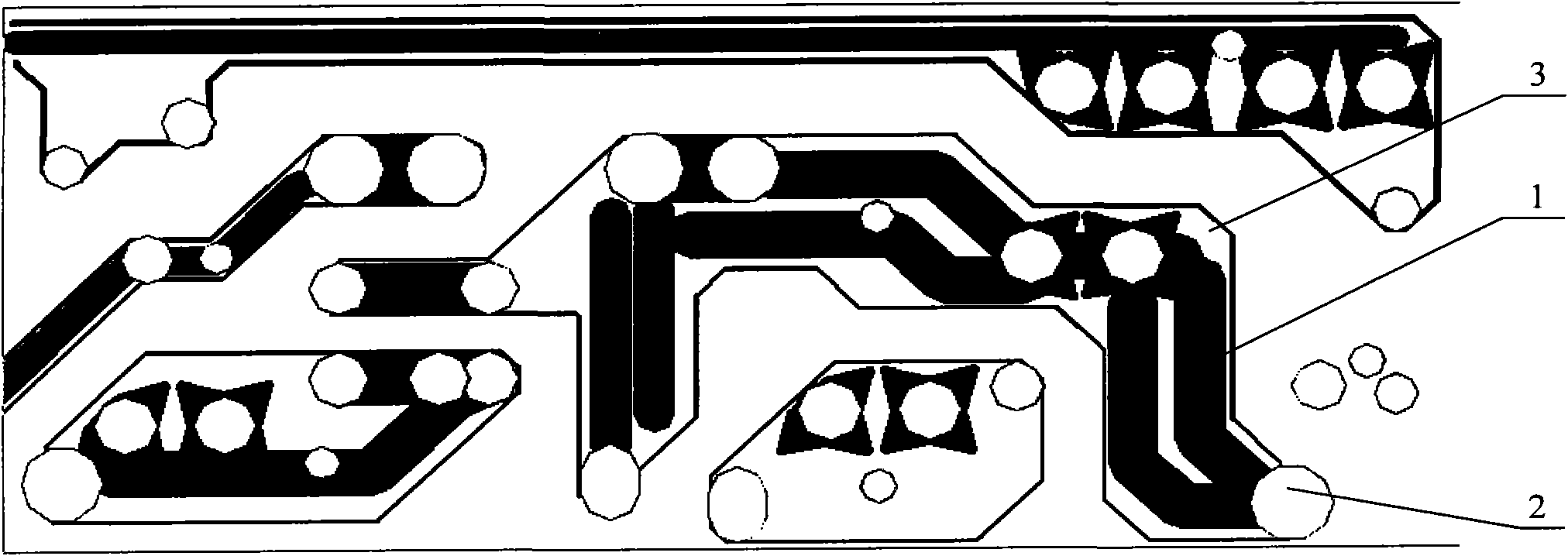

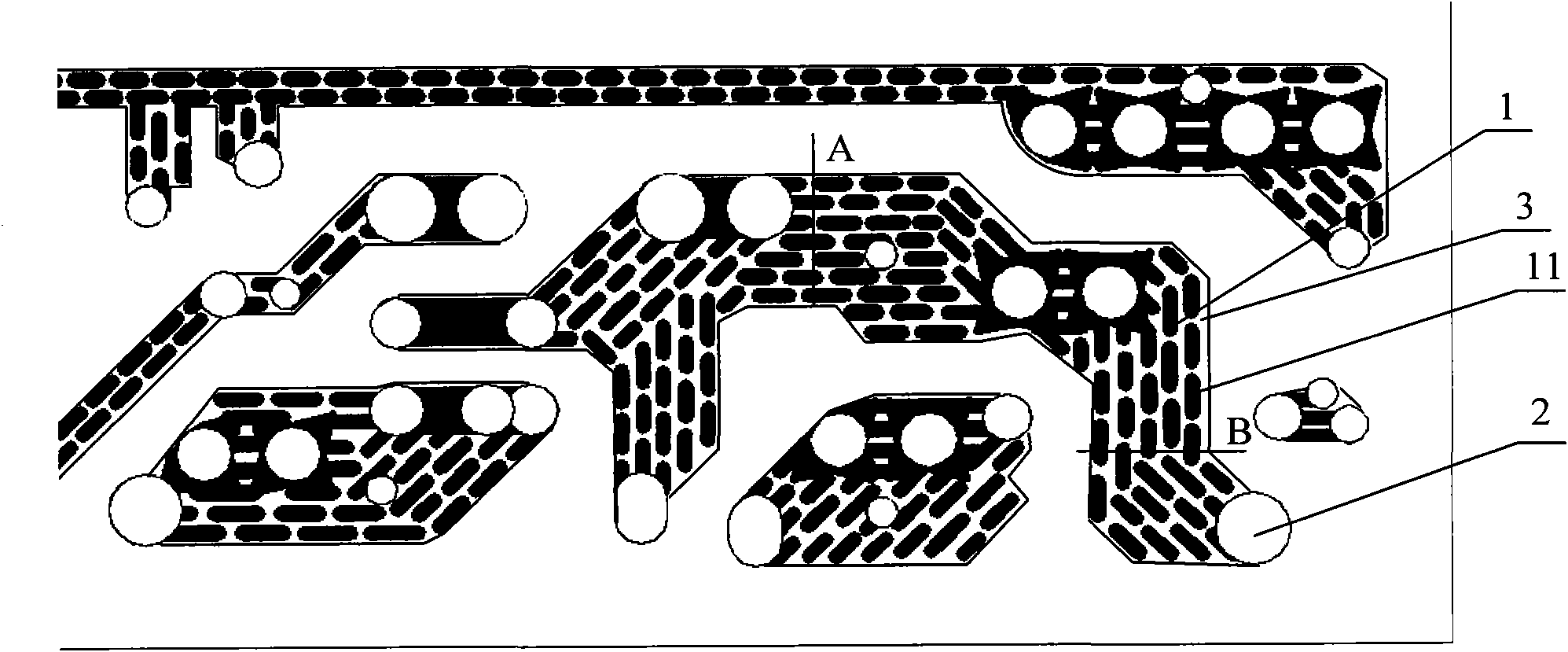

[0028] The embodiment of the present invention provides a printed circuit board tin hanging circuit 1, such as figure 2 As shown, the tin hanging circuit 1 includes several evenly distributed tin hanging bars 11, which are independent of each other and do not touch each other.

[0029] Because the solder is flowing, the existing wide tin-strip tin hanging circuit 1, during the wave soldering process, the solder will move along the slope direction of the tin hanging, resulting in less tin in the component pad 2, which affects the soldering firmness At the same time, the tin-hanging line 11 is not full and uniform enough, which will eventually affect the quality of the tin. Therefore, in order to avoid uneven tin loading caused by the flow of solder, the tin hanging circuit 1 is set to a structure where the tin hanging bars 11 are evenly distributed. The hanging tin bars 11 are independent of each other and do not touch each other. The solder on each hanging tin bar 11 is only It ...

Embodiment 2

[0035] The embodiment of the present invention provides a printed circuit board, such as figure 2 As shown, it includes: a tin hanging circuit 1 which includes a number of evenly distributed tin hanging bars 11, and the tin hanging bars 11 are independent of each other and do not touch each other.

[0036] Wherein, in order to enhance current carrying and heat dissipation, the long side of the tin hanging bar 11 is parallel to the direction of the tin hanging line 1, and several hanging tin bars 11 are staggered, so that the tin hanging area of the cross section of the entire tin hanging line 1 is maintained Consistent, so that the current carrying current of the whole hanging tin circuit 1 is consistent.

[0037] The structure of the tin-hanging circuit 1 in this embodiment is completely the same as the foregoing embodiment, and will not be repeated here.

[0038] In the technical solution of this embodiment, by setting the tin hanging circuit 1 of the printed circuit board as a ...

Embodiment 3

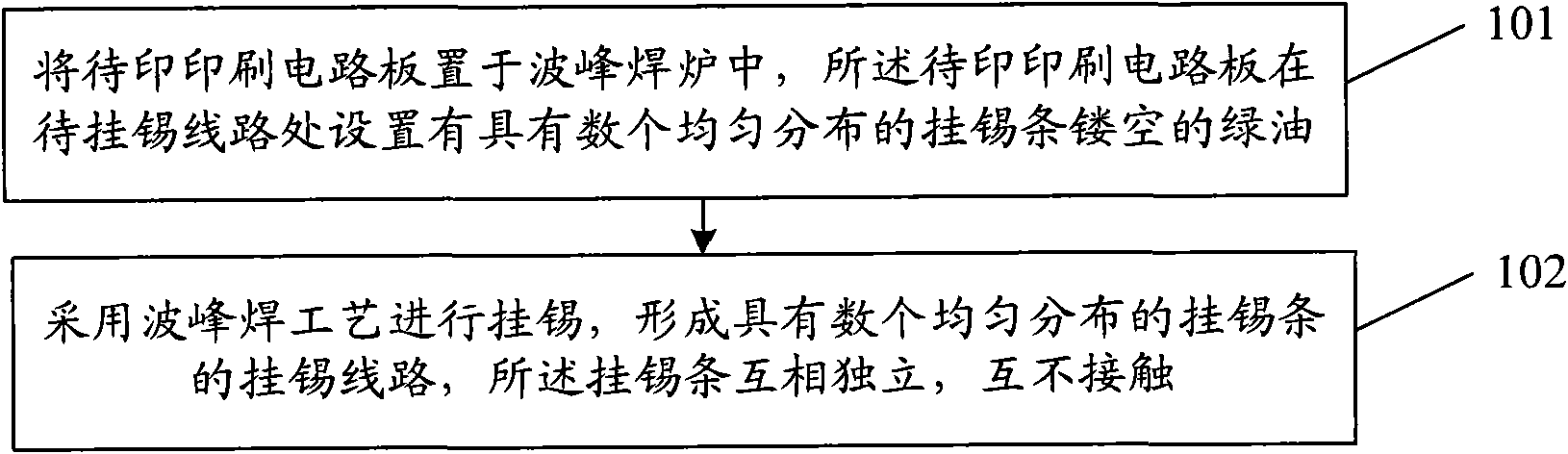

[0040] The embodiment of the present invention provides a tin hanging method, such as image 3 As shown, the method includes:

[0041] Step 101: Place the printed circuit board to be printed in a wave soldering furnace, and the printed circuit board to be printed is provided with a number of evenly distributed tin hanging strips hollowed out green oil at the line to be tinned;

[0042] Step 102: Perform tin hanging by using a wave soldering process to form a tin hanging circuit with a number of evenly distributed tin hanging bars, which are independent of each other and do not touch each other.

[0043] Wherein, the long sides of the formed tin hanging bar are parallel to the direction of the tin hanging line, and the tin hanging bars are arranged in a staggered manner, so that the tin hanging area of the cross section on the entire tin hanging line remains consistent.

[0044] In the technical solution of this embodiment, a printed circuit board to be printed with a number of evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com