In-groove snap fastener

A fastener and firmware technology, applied in the direction of fasteners, press fasteners, press fasteners, etc., can solve problems such as complex and bloated structures, and achieve the effects of reducing manufacturing complexity, reducing material consumption, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

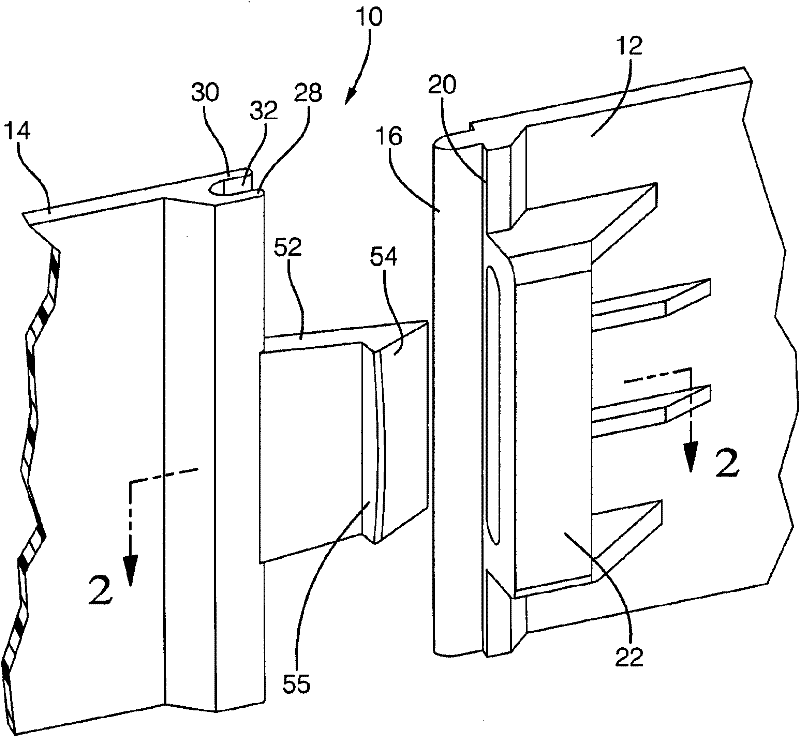

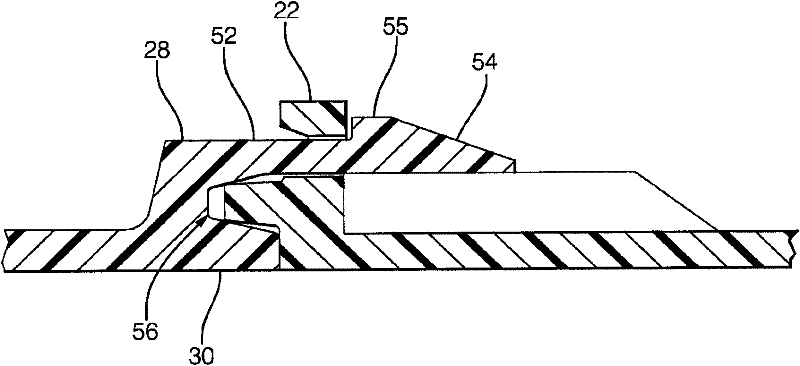

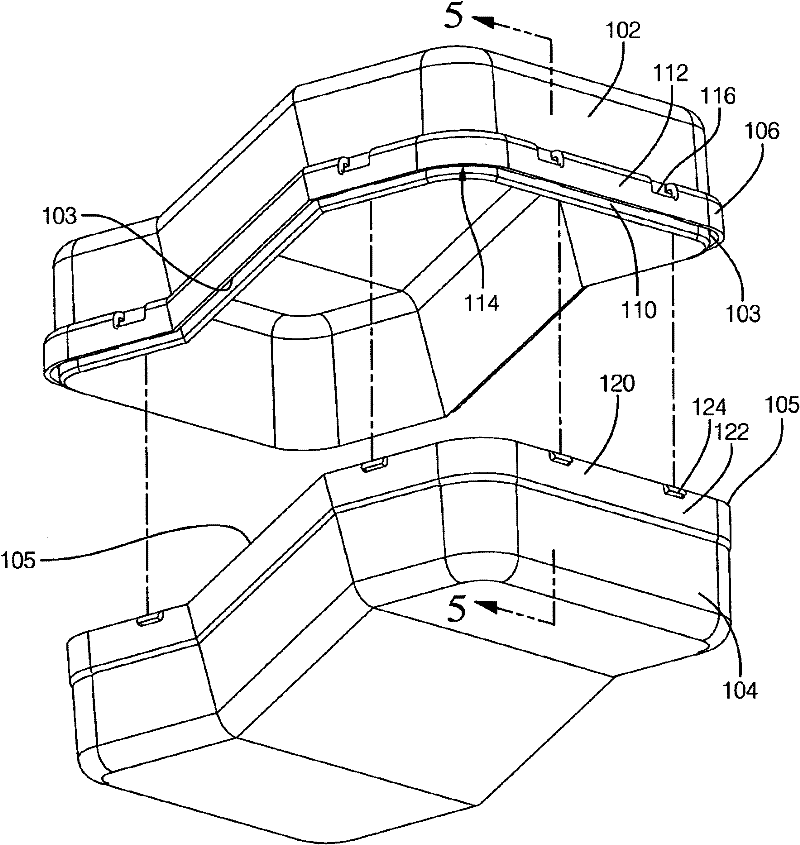

[0019] A perspective view of a prior art snap tab fastener 10 for connecting two housing members 12 , 14 of an HVAC module is shown in FIG. 1 . FIG. 2 shows a cross-sectional view of the snap tab fastener 10 of FIG. 1 taken along section line 2-2. As best shown in FIG. 1 , extending from the first housing member 12 is a tongue 16 and a ring frame 22 adjacent to and positioned above the tongue 16 . Extending from the second housing member 14 are a first slot member 28 and a second slot member 30 defining a slot 32 therebetween. The slot 32 is oriented toward the first housing member 12 and is adapted to receive the tongue 16 extending from the first housing member 12 to form a substantially airtight seal. Extending from the first channel member 28 is a tab 52 including a locking member 55 having a ramped end 54 . The ramped end 54 is adapted to elastically deform the ring frame 22 to position the locking member 55 to lock the tab 52 to the ring frame 22 , thereby securing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com