High-intensity discharge lamp

A discharge lamp and high-brightness technology, applied in the direction of discharge lamps, gas discharge lamps, discharge tubes, etc., can solve the problems of high cost, cracks in the thin tube, welding and falling off of the placement part, etc., and achieve stable contact area, good starting performance, Effect of Stable Starting Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

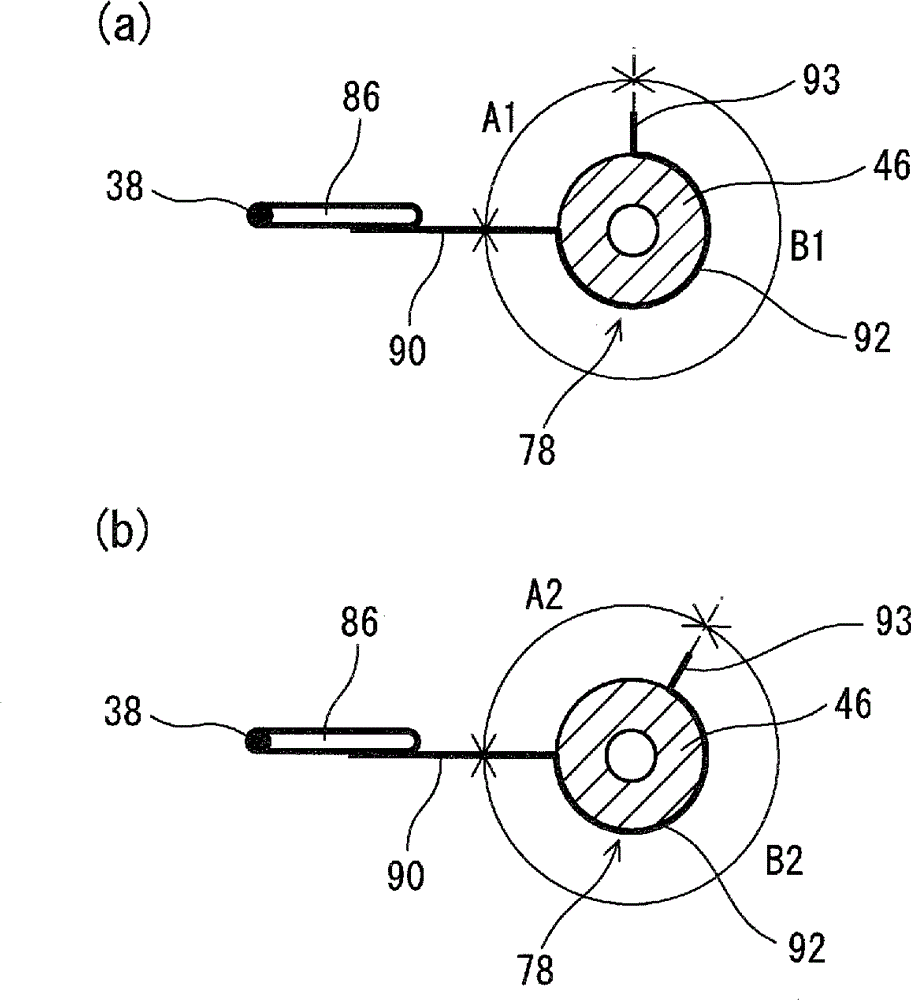

[0055] Next, metal halide lamps according to embodiments of the present invention will be described with reference to the accompanying drawings.

[0056] 1. Structure

[0057] (1) Lighting device

[0058] First, an example of a lighting device including a metal halide lamp (hereinafter also simply referred to as a "lamp") according to an embodiment will be described.

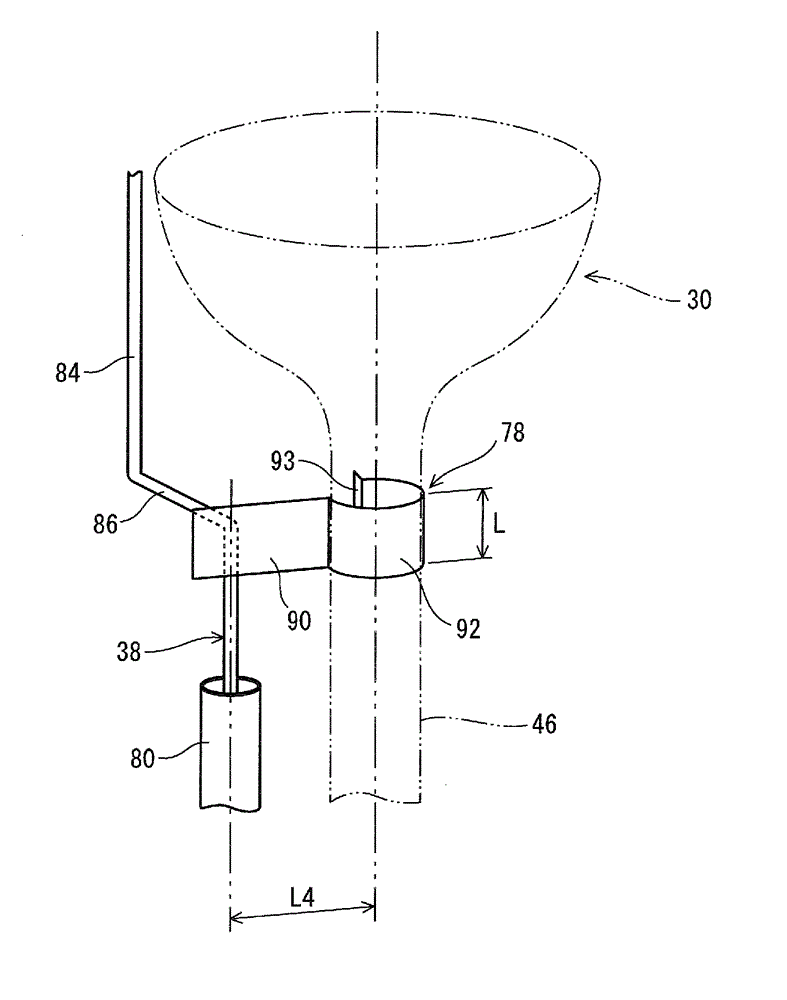

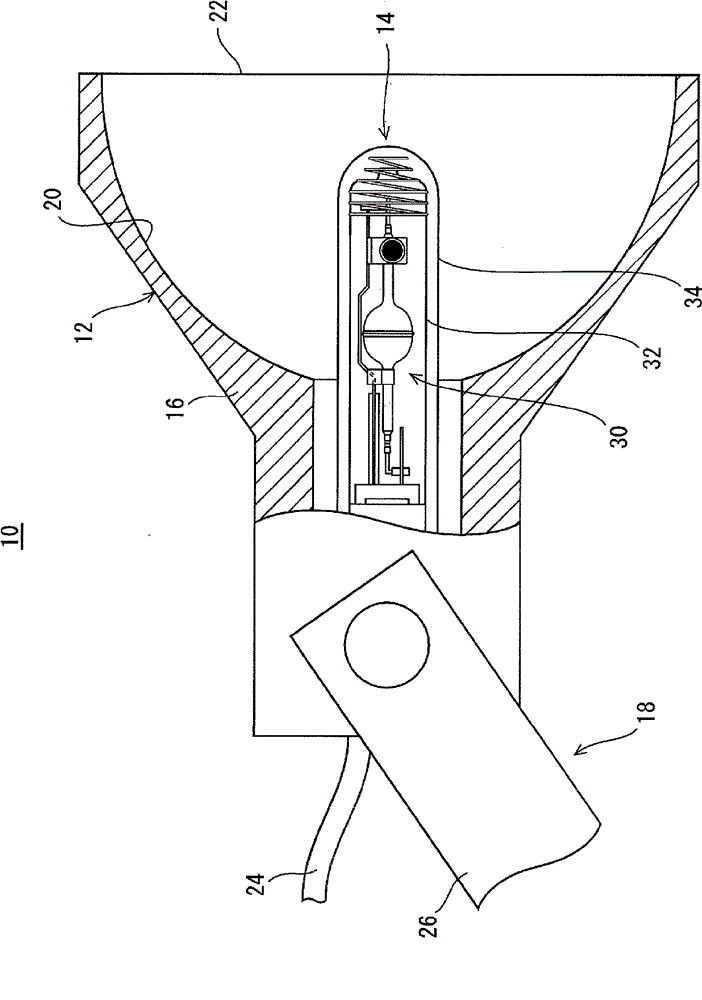

[0059] figure 1 It is an overall view of a lighting device 10 having a metal halide lamp according to this embodiment, and a part is cut away so that the inside of a lighting fixture 12 can be seen.

[0060] Lighting device 10 such as figure 1 As shown, it consists of a lighting fixture 12 and a lamp 14 mounted on the lighting fixture 12 . In addition, although this lighting fixture 12 is for a spotlight, the metal halide lamp of embodiment is also mounted and used in the lighting fixture of other uses, such as so-called base lighting (base light).

[0061] The lighting fixture 12 has a reflector 16 that refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com