Fixing mechanism for superheater coiled pipe

A fixed mechanism and superheater technology, applied in the mechanical field, can solve the problems of low strength, easily damaged superheater serpentine tube, poor stability, etc., and achieve the effect of high stability, high practical value and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

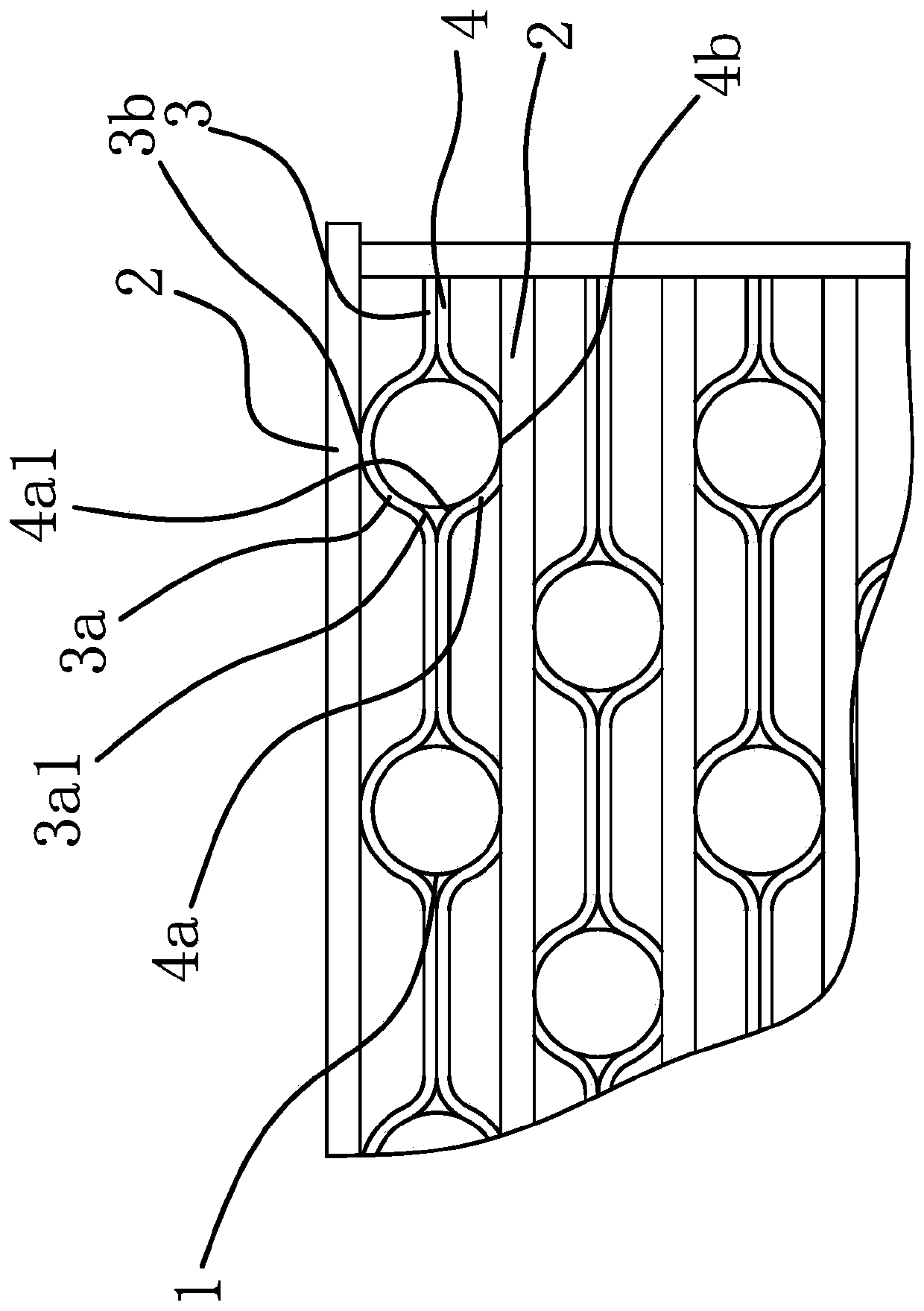

[0026] Such as figure 1 As shown, the coiled tube of the superheater includes several adjacent tube sections 1 .

[0027] The fixing mechanism of the serpentine tube of the superheater is arranged between two adjacent pipe sections 1, including a plurality of partition plates 2, a positioning plate 3 and a positioning plate 2 4, and the positioning plate 1 3 has a number of recesses along its length direction. The positioning notch one 3a of the above-mentioned positioning plate two 4 has several concave positioning notches two 4a along its length direction, and the above-mentioned positioning plate one 3 and positioning plate two 4 are tightly pressed on the two adjacent partitions up and down 2 and the positioning plate one 3 and the positioning plate two 4 abut against each other, the above-mentioned positioning notch one 3a corresponds to the positioning notch two 4a one by one, through the positioning notch one 3a and the positioning notch two 4a on the positioning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com