Spherical roller end face grinding machine

A technology of end grinding machine and spherical roller, which is applied to machine tools, grinding/polishing equipment, grinding machines, etc., which are suitable for grinding workpiece planes, and can solve the problems of unguaranteed accuracy, high cost, and low efficiency, and achieve reduction Processing cost, the effect of improving processing accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

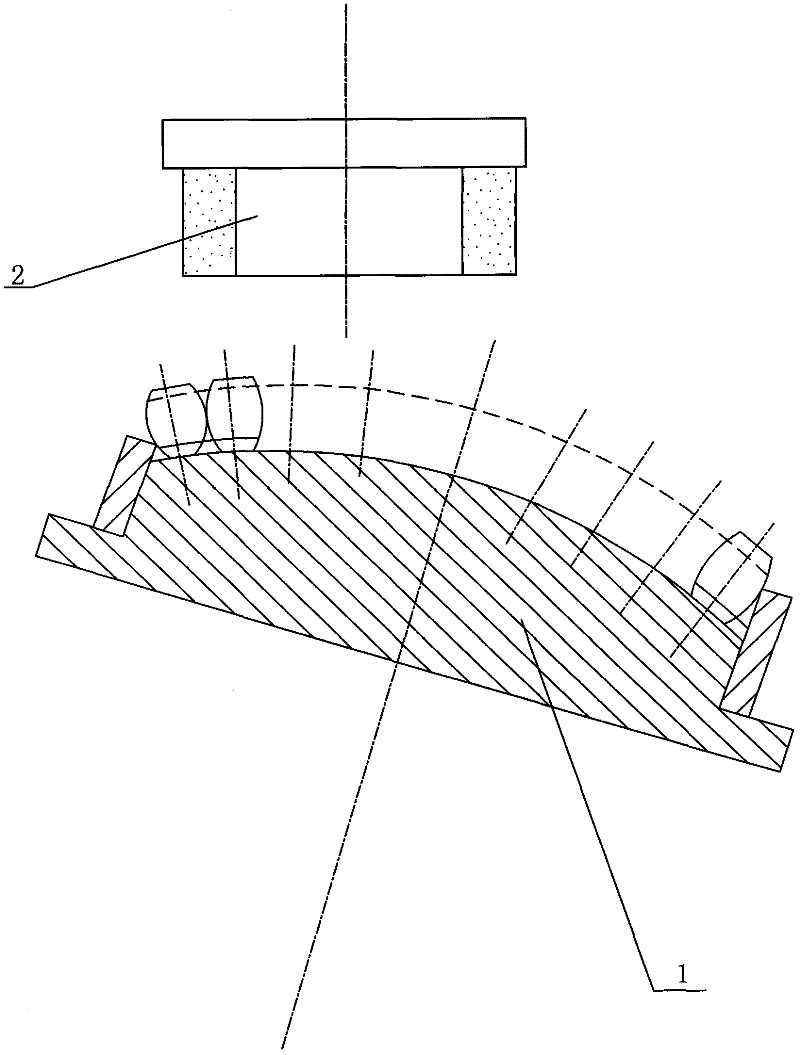

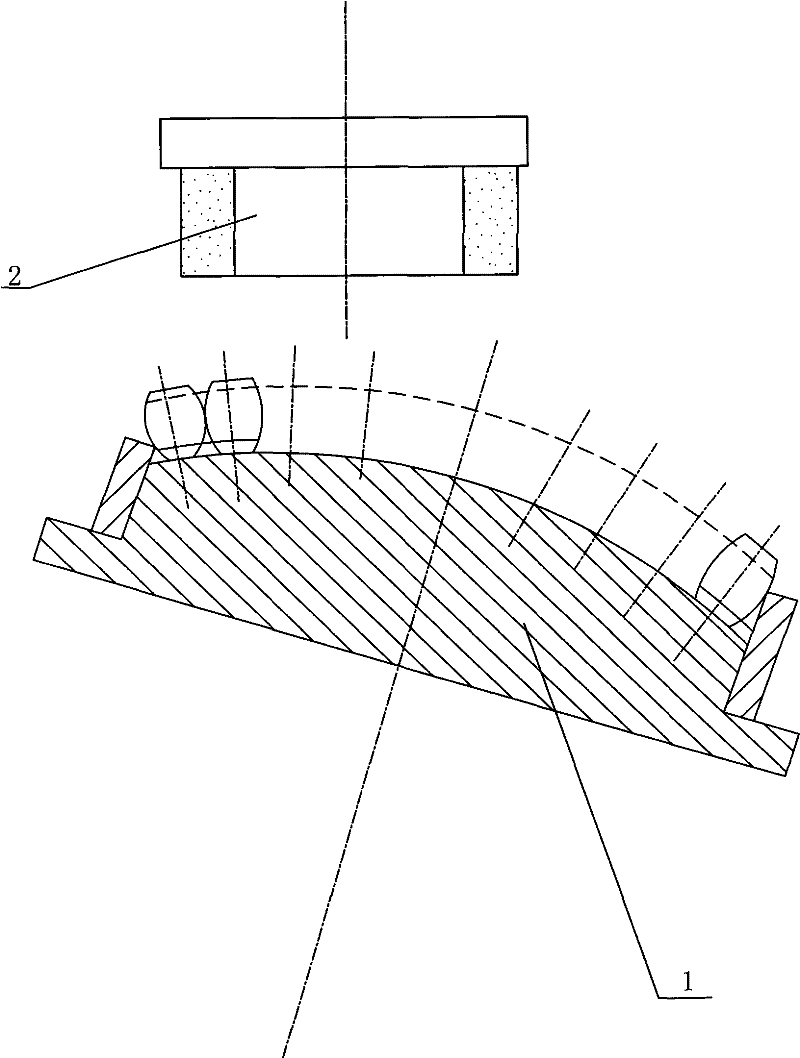

[0008] Such as figure 1 As shown, a spherical roller end grinding machine includes a flat end surface grinding wheel, the grinding end of the grinding wheel 1 is set downwards, and the upper end of the grinding wheel 1 is connected to a motor; a convex spherical electromagnetic chuck 2 is arranged below the grinding wheel 1; Limit stoppers are arranged on both sides of the electromagnetic chuck 2; the convex spherical surface on the upper end surface of the electromagnetic chuck 2 forms a groove with the stoppers on both sides; the center of the convex spherical surface of the electromagnetic chuck 2 is provided with a rotating shaft connected to the drive motor. The spherical roller to be processed is adsorbed on a convex spherical electromagnetic chuck through the processed concave spherical end surface, and then the other flat end surface of the processed roller is ground with a concave spherical grinding wheel to make it a convex spherical surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com