Anti-vibration device

A technology for vibration isolation and installation of components, which is used in power plants, jet propulsion devices, internal combustion propulsion devices, etc. It can solve the problems of limited load resistance, limited spring tuning freedom, and difficulty in protruding from large heights, and achieve excellent load resistance. performance, sufficient durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

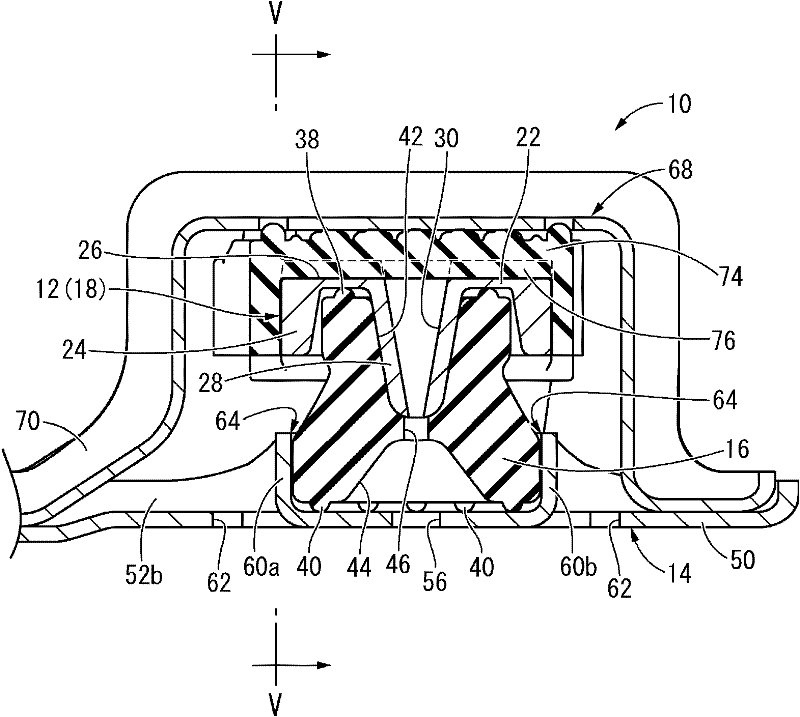

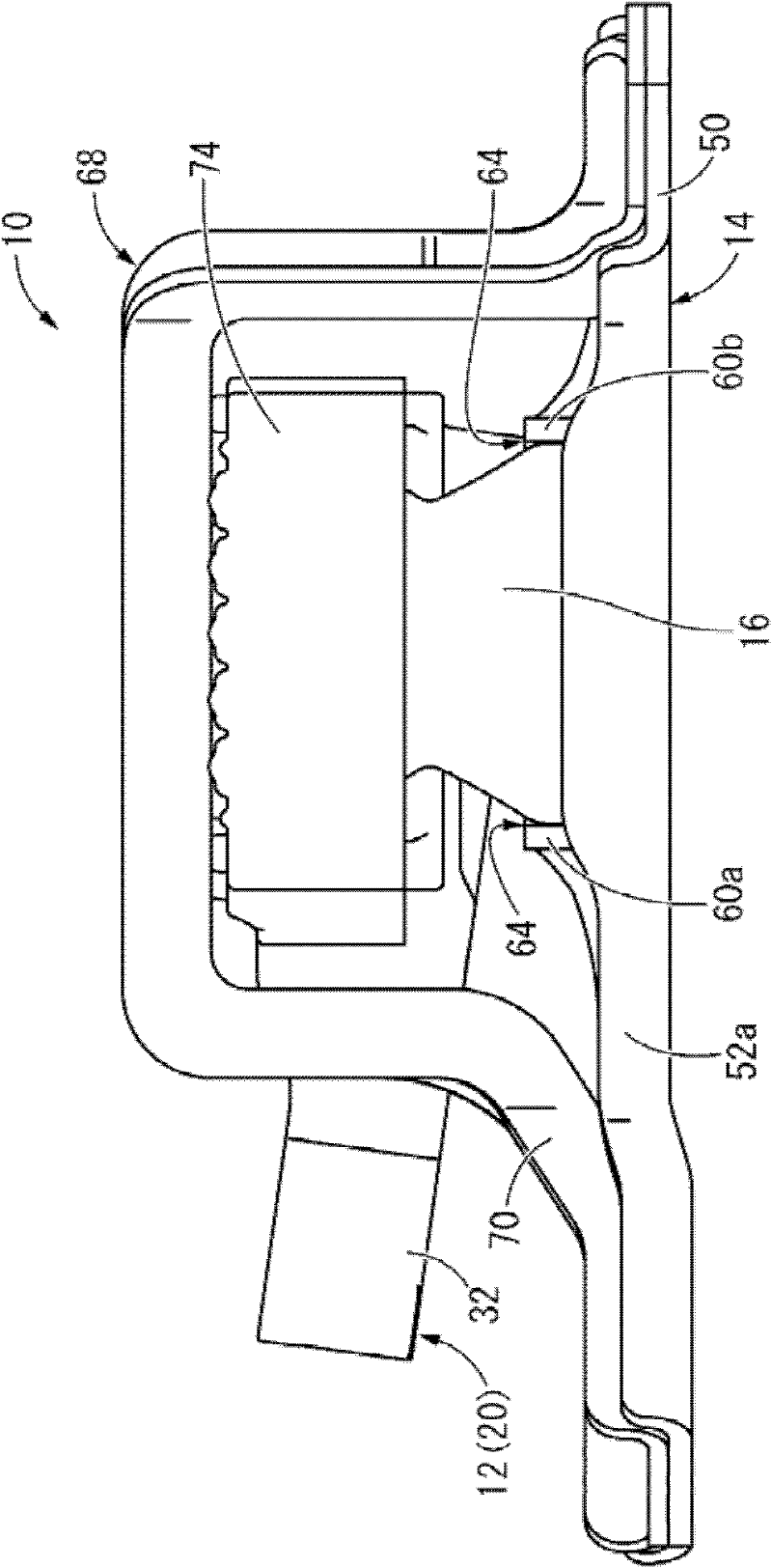

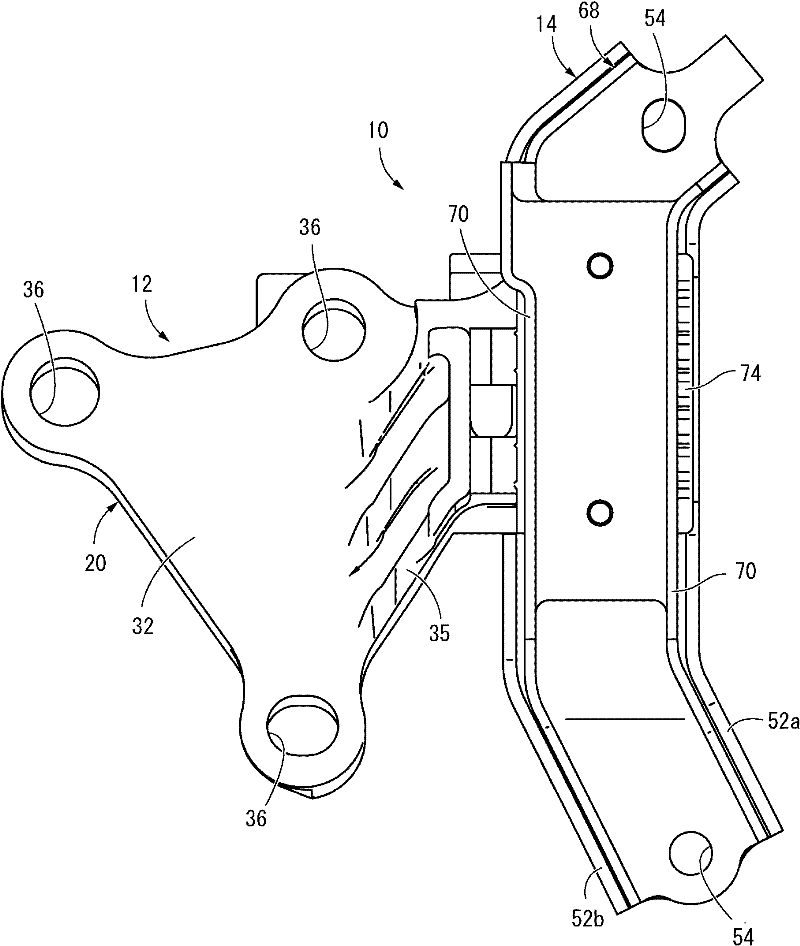

[0042] exist Figure 1 to Figure 5 In the figure, an engine mount 10 for an automobile is shown as one embodiment of a vibration isolating device having a structure based on the present invention. The engine mount 10 has a structure in which a first mounting member 12 and a second mounting member 14 opposed to each other in the axial direction are connected by a main body rubber elastic body 16 disposed between opposing surfaces of the mounting members 12 , 14 . Furthermore, the first mounting member 12 is mounted to a not-shown power component, and the second mounting member 14 is mounted to a not-shown vehicle body, thereby supporting the power component by vibration isolation of the vehicle body. In addition, in Figure 1 to Figure 5 In , the engine mount 10 in a single state before being mounted on a vehicle is shown. In addition, in the following description, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com