Die pressing method and device for blank of porcelain insulator

A technology of porcelain insulators and blanks, applied in the direction of forming indenters, etc., can solve the problems of backward equipment, unstable quality, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

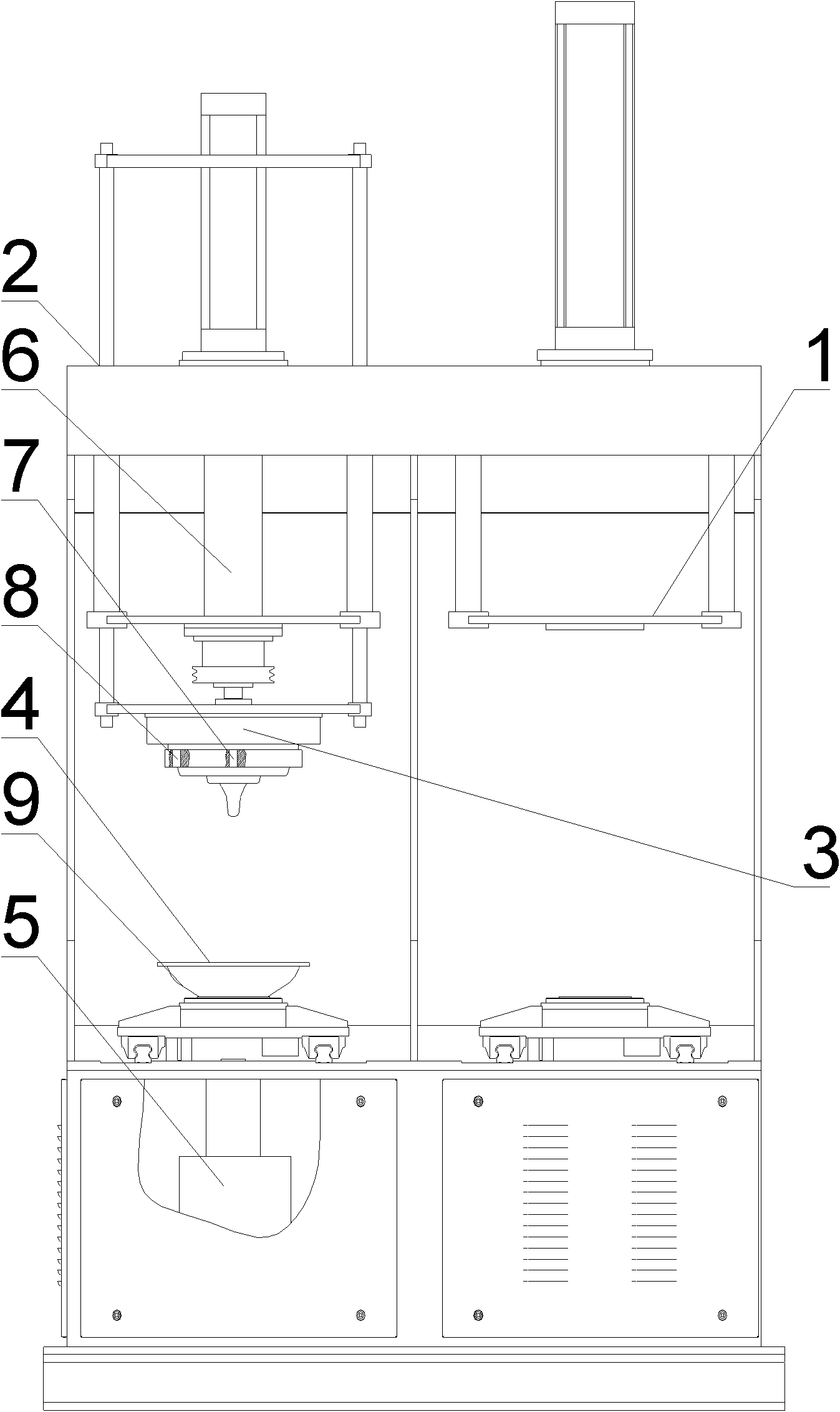

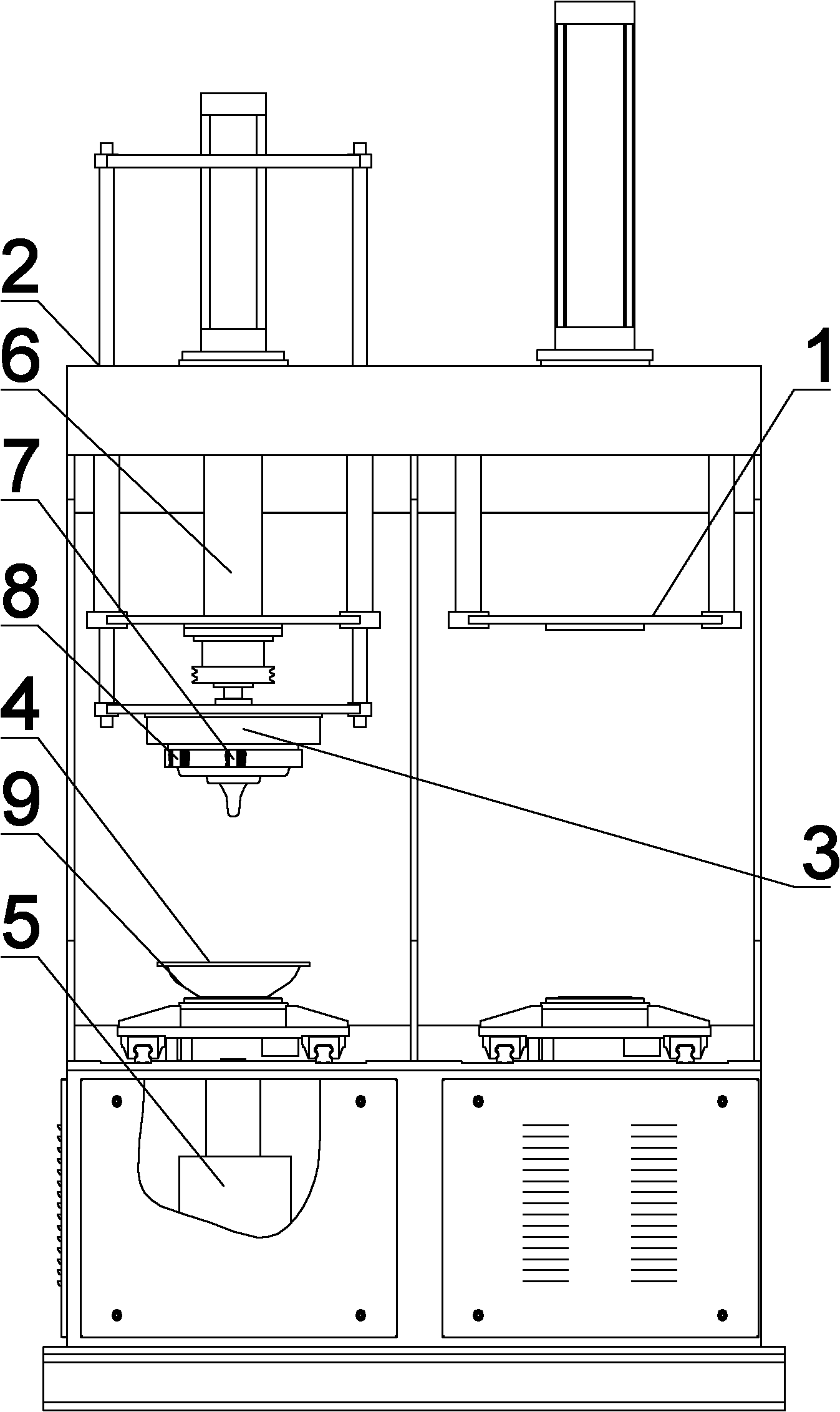

[0015] Embodiment of the present invention: porcelain insulator blank molding device, such as figure 1 As shown, it includes a pre-pressing device 1 that pre-presses the blank, and a molding device 2 is arranged next to the pre-pressing device 2. The structure of the molding device 2 includes an upper mold 3 and a lower mold 4, and a rotary motor 5 is connected below the lower mold 4. A lift cylinder 6 is connected above the upper mold 3 . A release agent nozzle 7 is installed in the upper mold 3, and the release agent nozzle 7 is connected to a release agent injection device to prevent the blank from bonding to the upper mold 3.

[0016] An air nozzle 8 is installed in the upper mold 3, and the air nozzle 8 is connected with an air compressor. After the blank is molded, the residual mud in the upper mold can be removed.

[0017] The gypsum layer 9 is coated on the surface of the lower mold 4, which can have enough friction in the molding process to drive the blank to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com