Loosing and dampening device of tobacco leaves

A technology for loosening moisture and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems affecting the processing quality and uneven moisture in the loose dampening cylinder, and achieve the effect of good loosening effect, uniform moisture content and uniform moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following description is made with reference to specific embodiments.

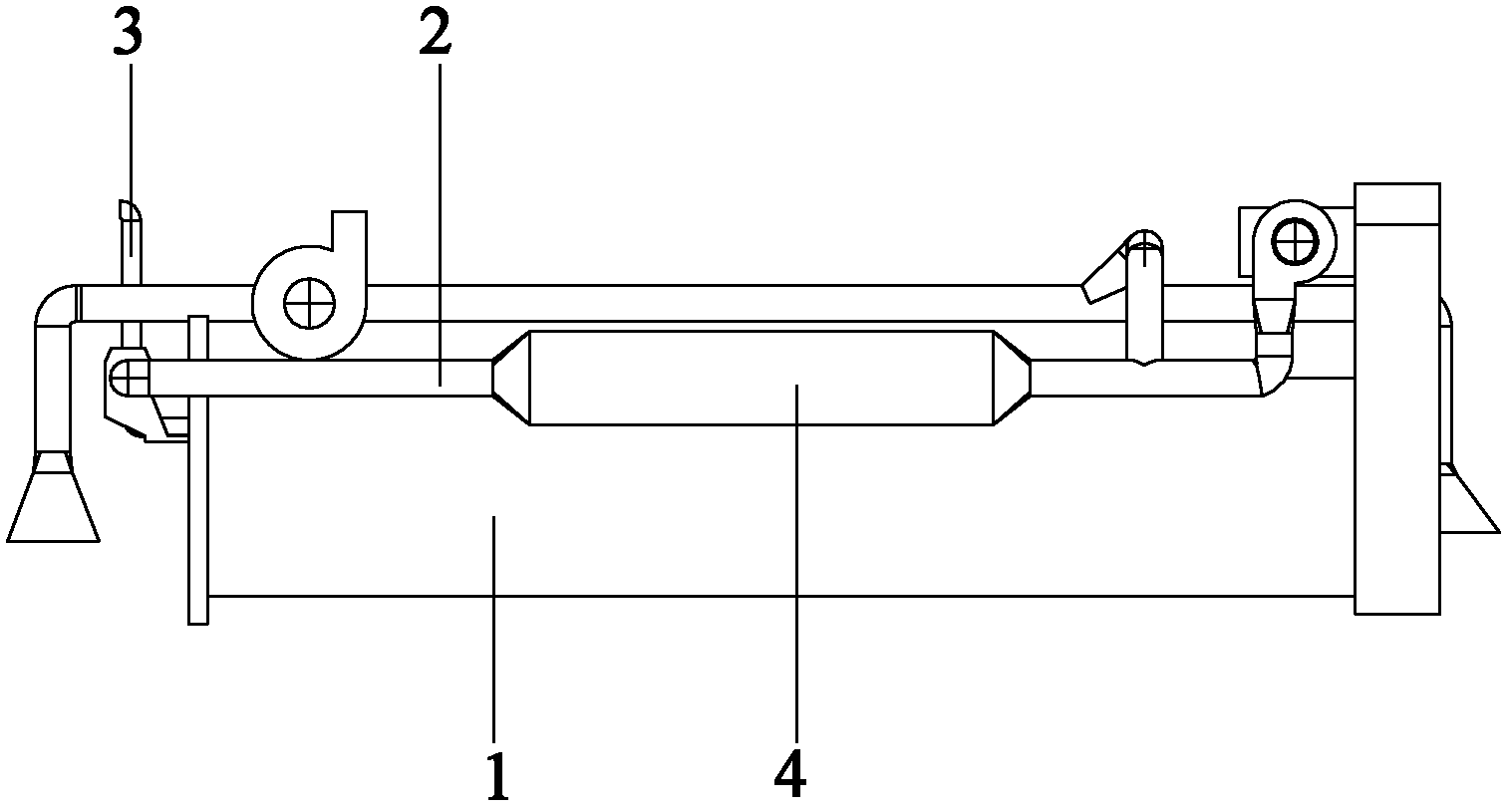

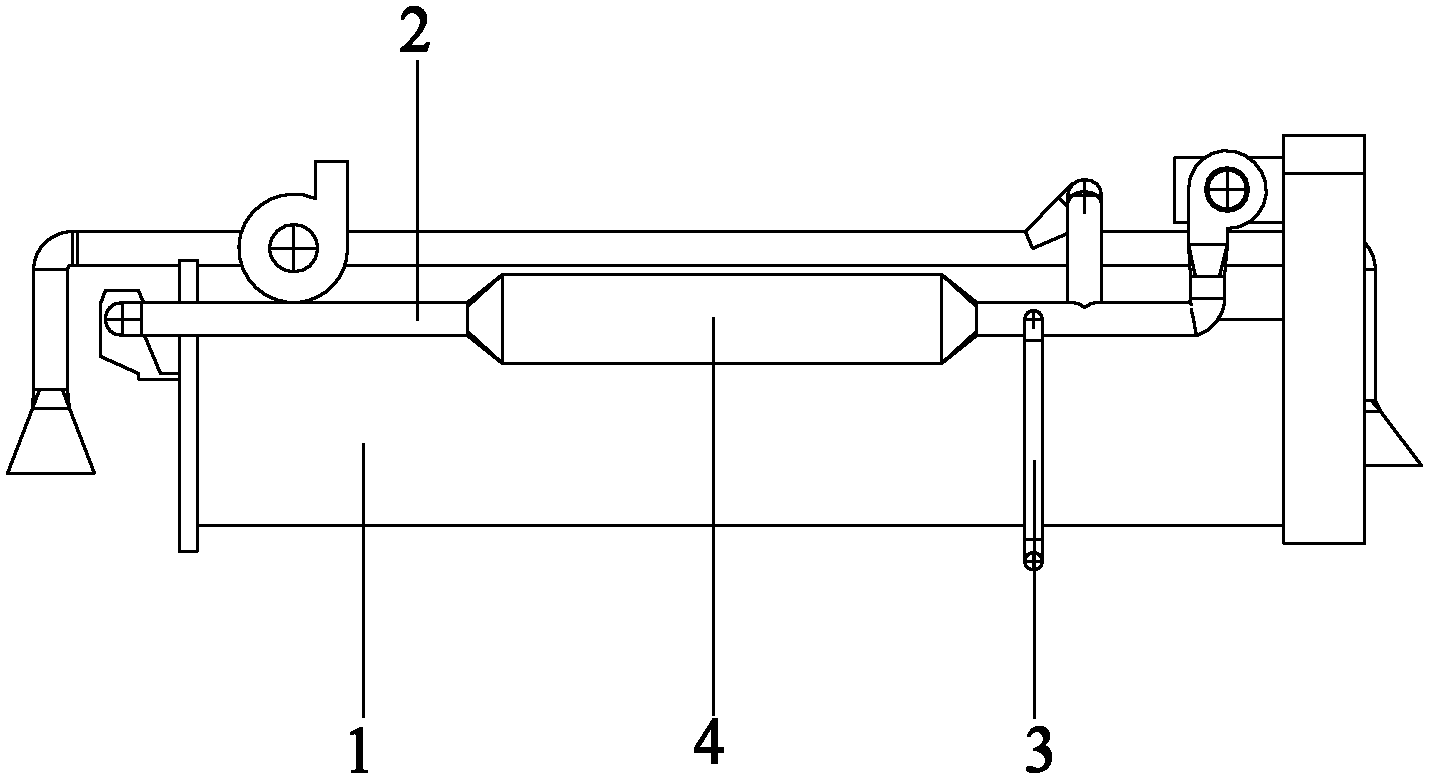

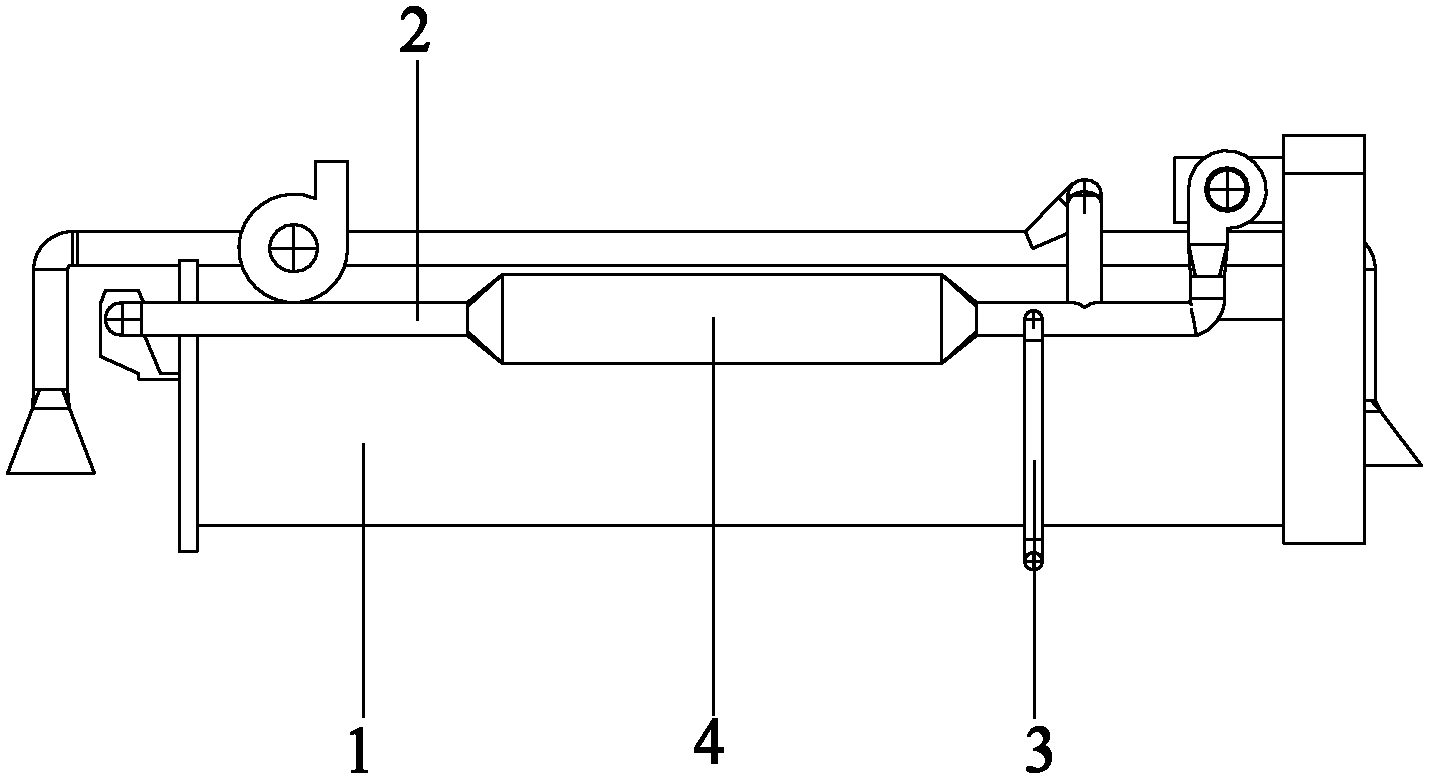

[0013] See figure 2 , the figure is a schematic structural diagram of the device for loosening and moisturizing tobacco leaves in the present invention.

[0014] The loose moisture regaining device for tobacco leaves provided by the present invention includes a loose moisture regaining cylinder 1, a return air pipe 2 and a steam pipe 3. The return air pipe 2 is provided with a heater 4, the return air pipe 2 is communicated with the loose moisture regaining cylinder 1, and the steam pipe 3 The steam pipe 3 is arranged at the rear end of the heater 4 and is arranged on the return air pipe 2 and communicated with the return air pipe 2 .

[0015] The diameter of the return air duct 2 is 145mm-165mm. Preferably, the diameter of the air return pipe is 155mm.

[0016] The diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com