Arc striking control method for gas metal arc welding and welding machine therefor

A technology of molten electrode gas and control method, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., and can solve problems such as prolonging welding time, wire collapse, and affecting welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

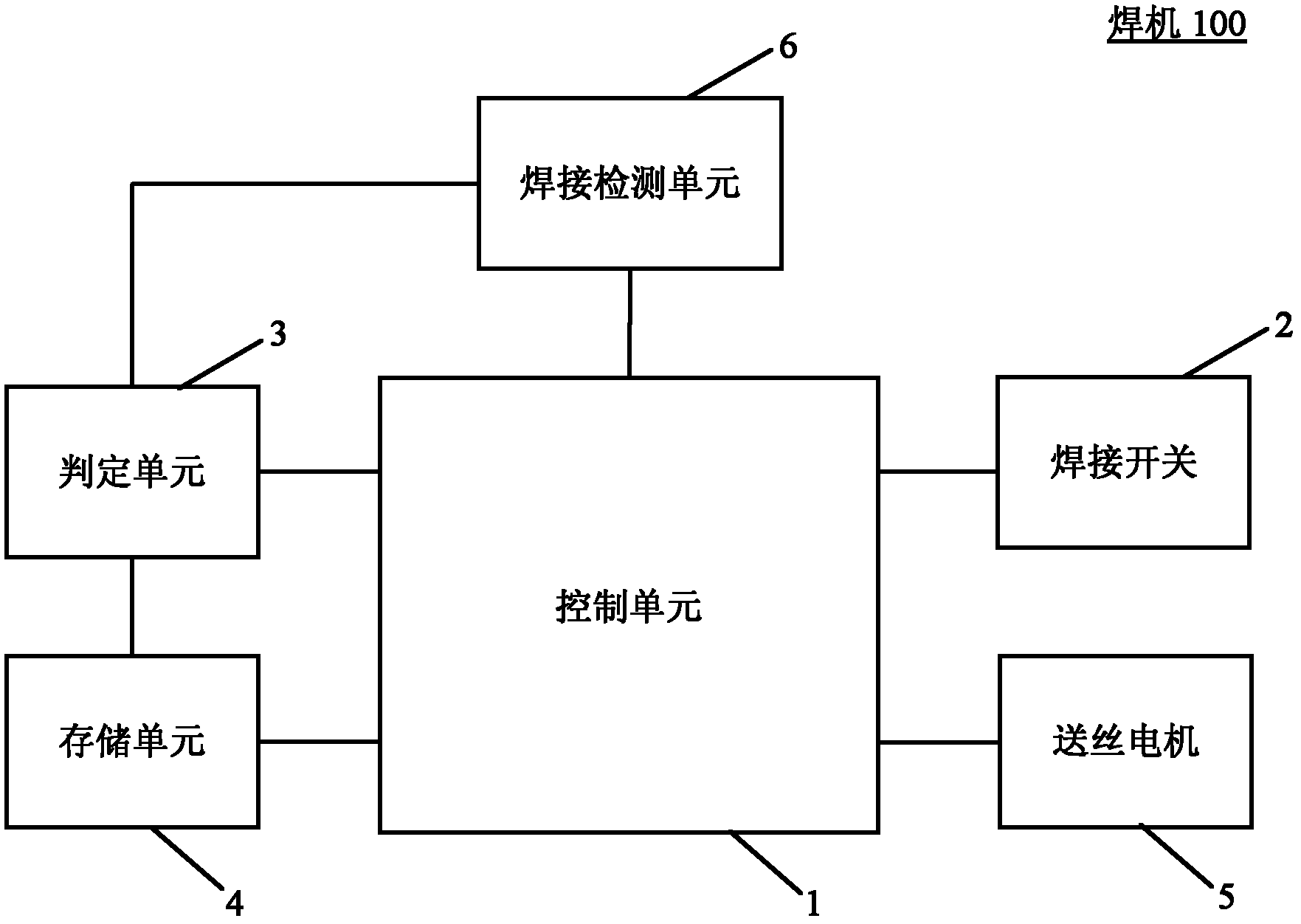

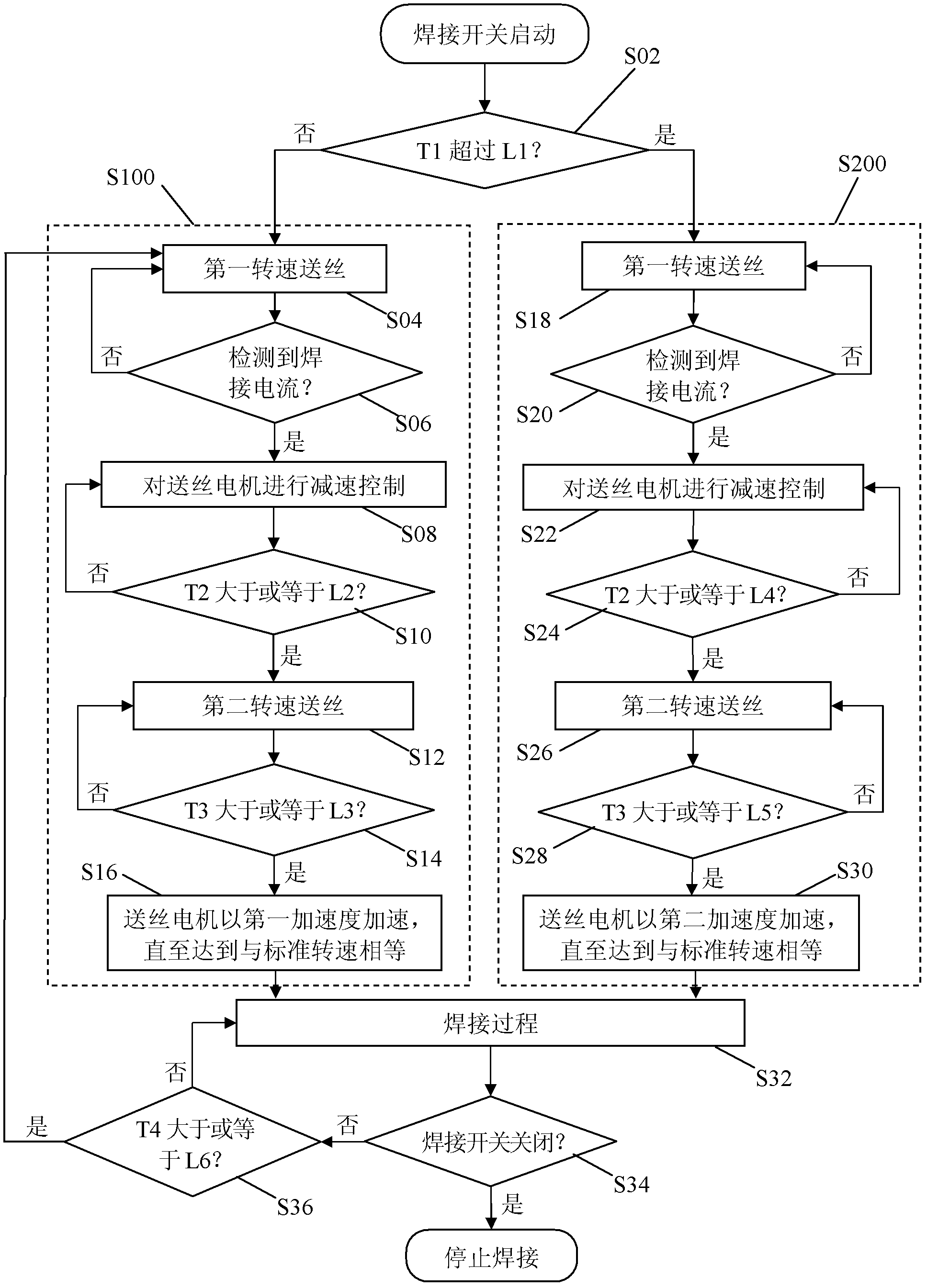

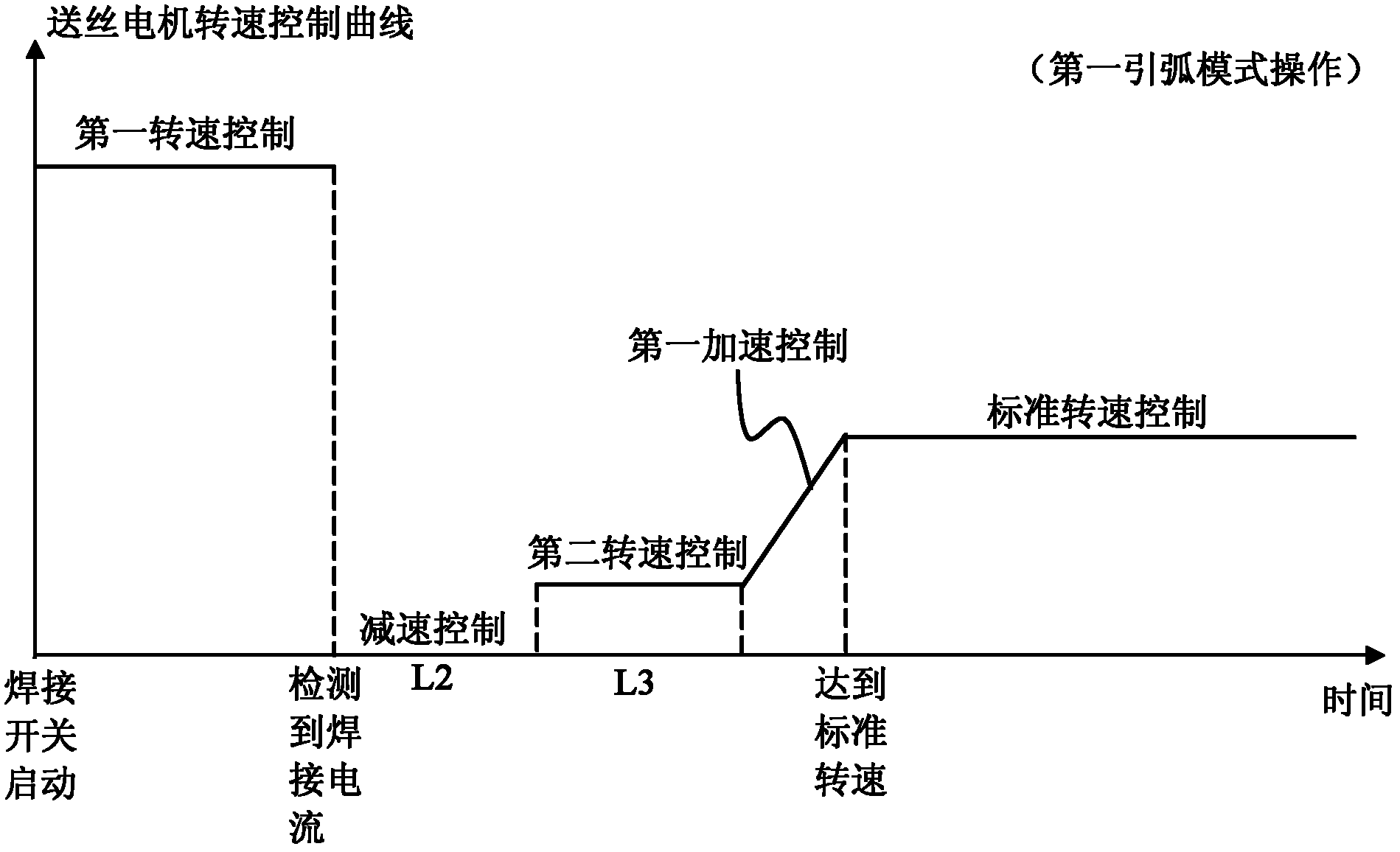

[0016] figure 1 It is a schematic diagram of the gas-shielded arc welding machine of the present invention. like figure 1 As shown, the welding machine 100 includes: a control unit 1 , a welding switch 2 , a determination unit 3 , a storage unit 4 , a wire feeding motor 5 and a welding detection unit 6 . The control unit 1 is respectively connected with the welding switch 2 , the determination unit 3 , the storage unit 4 , the wire feeding motor 5 and the welding detection unit 6 , and is used for controlling the arc striking operation of the welding machine 100 . The determination unit 3 is connected to the storage unit 4 and the welding detection unit 6 respectively, and is used to determine whether to proceed to the next step according to the parameters pre-stored in the storage unit 4 and the parameters detected by the welding detection unit 6 . The storage unit 4 is used to store preset parameters, including: welding stop time limit L1, first time limit L2, first slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com