Fuel pump rotor shaft assembling device of heater for vehicle

A vehicle heater and rotor shaft technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex assembly process, difficult to ensure assembly quality, low assembly efficiency, etc., to ensure assembly quality and improve assembly. Efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

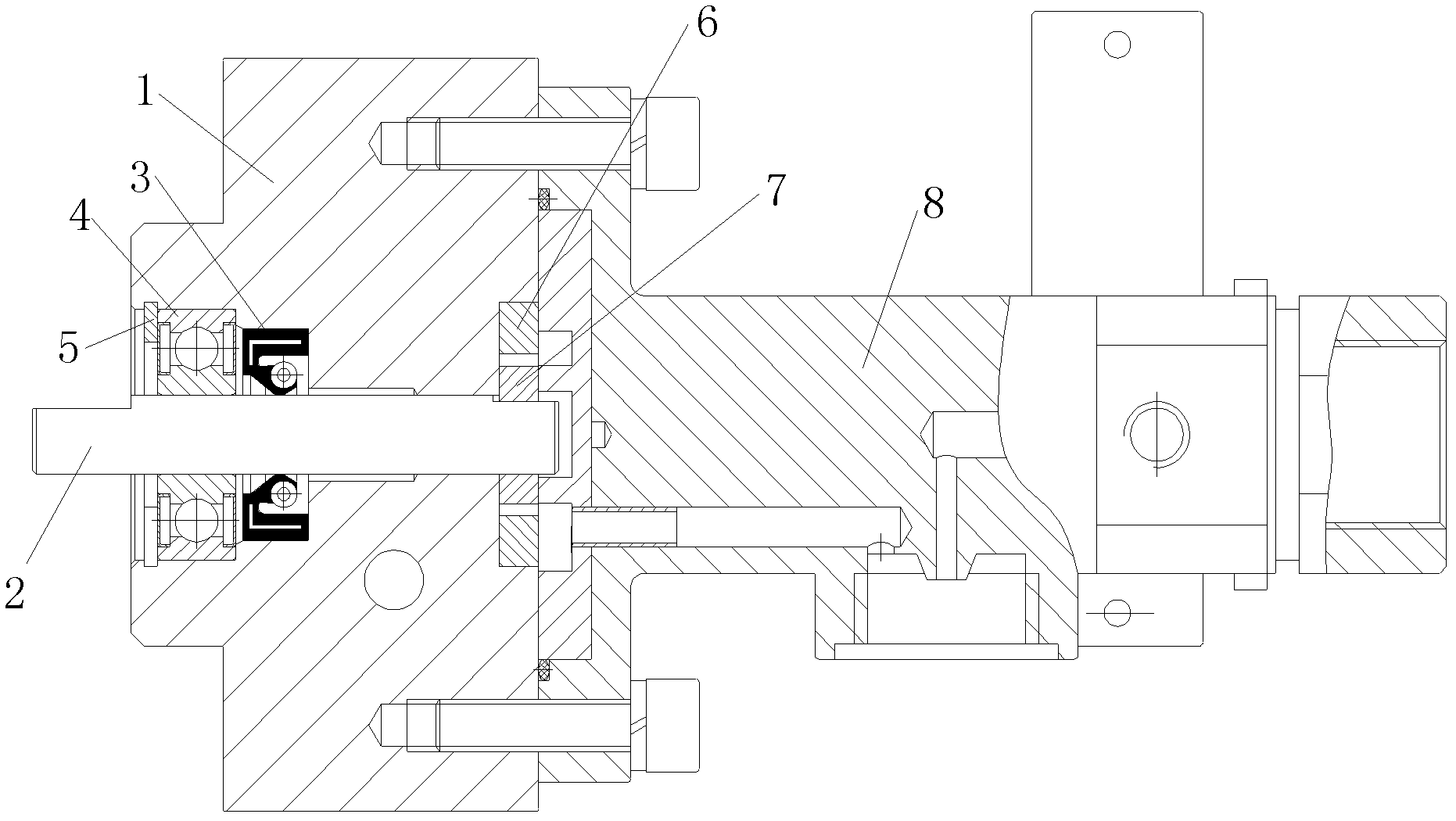

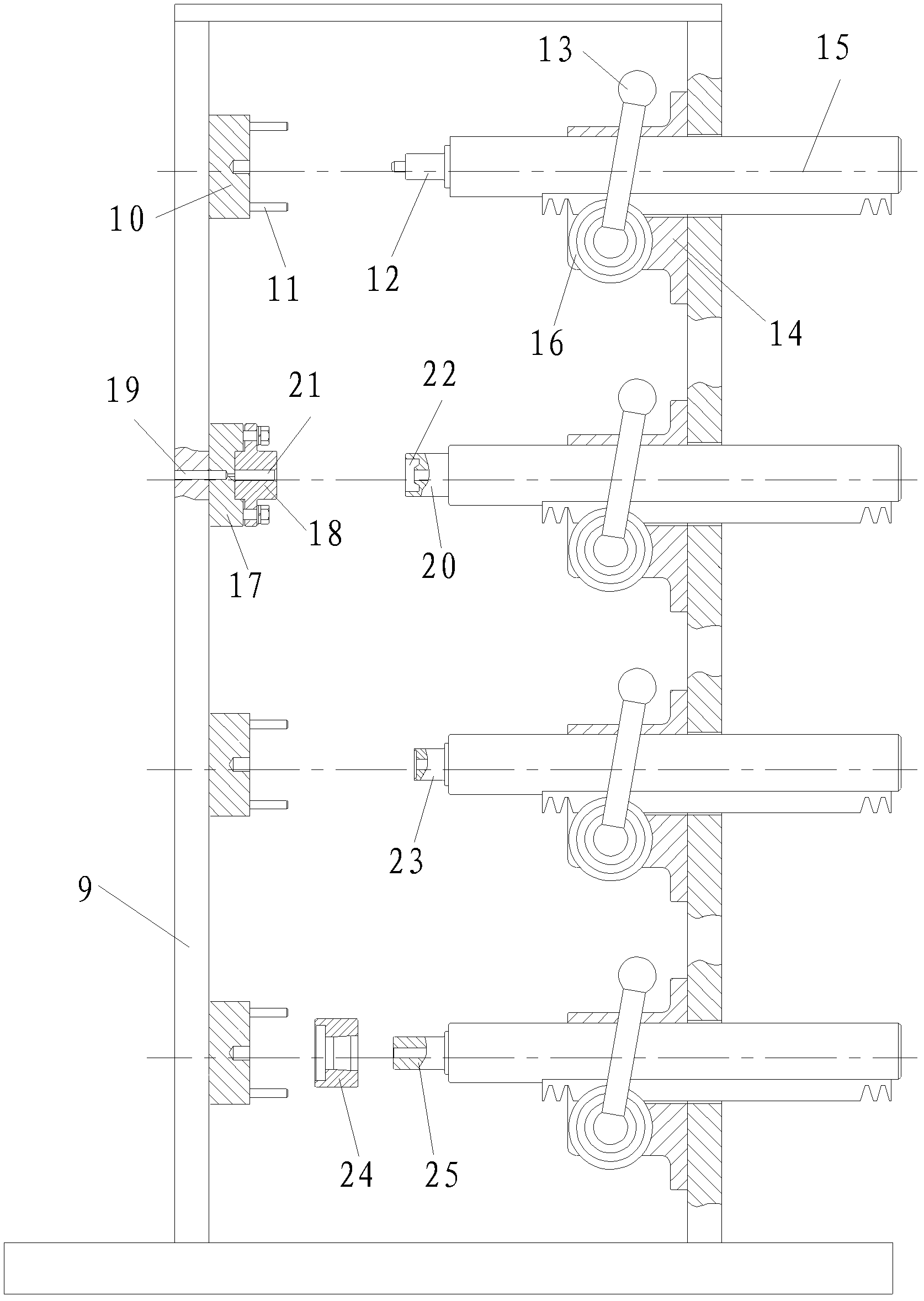

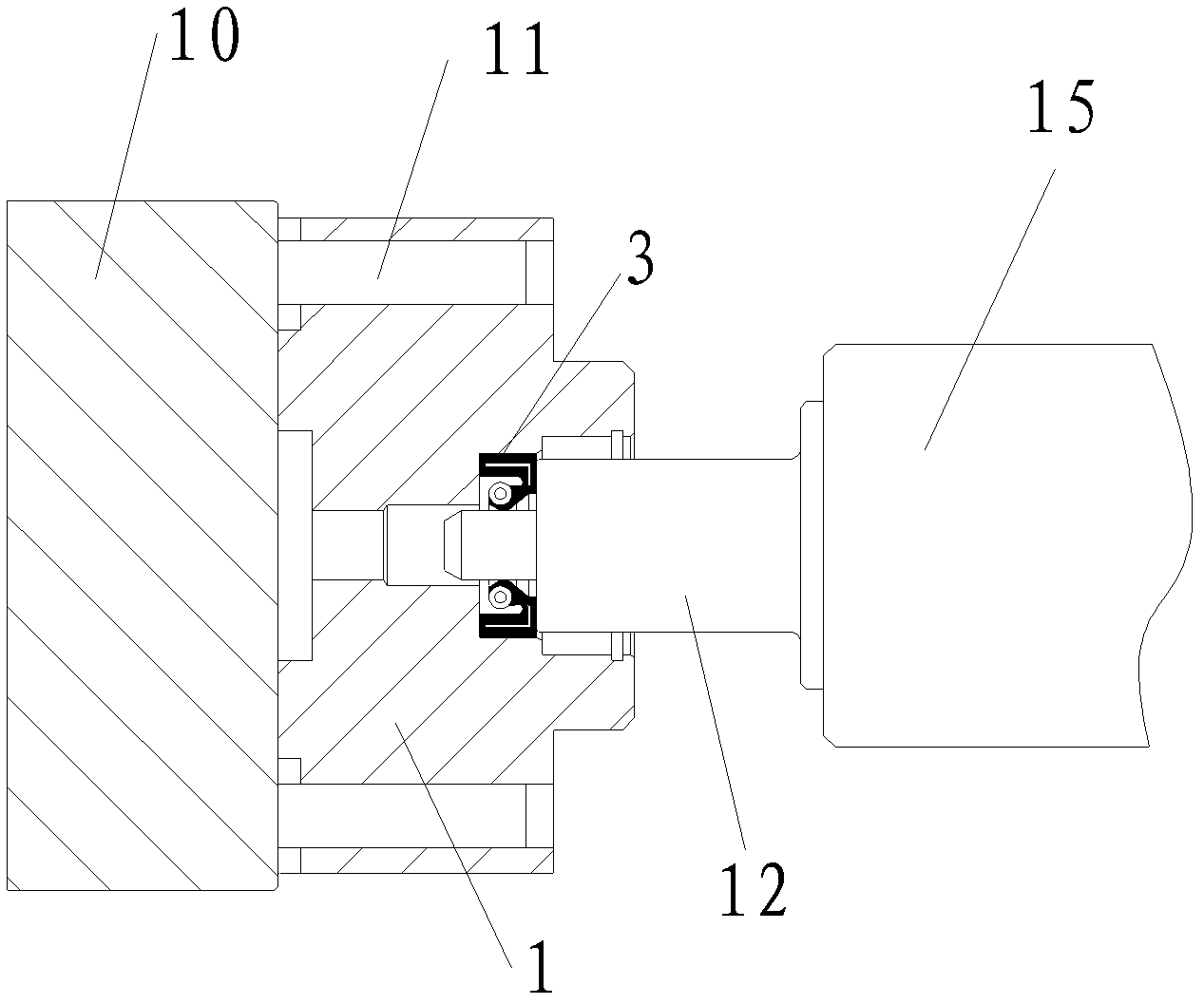

[0015] Such as figure 2 As shown, the vehicle heater fuel pump rotor shaft assembly device of the present invention includes a frame 9, an oil seal press-fit mechanism, a bearing press-in rotor shaft mechanism, a bearing press-in pump body mechanism and a bearing retaining ring press-in pump body mechanism, and the oil seal The press-fit mechanism, the bearing press-in rotor shaft mechanism, the bearing press-in pump body mechanism and the bearing back-up ring press-in pump body mechanism are installed on the frame 9 from top to bottom. The specific structure and press-fitting process of the oil seal press-fit mechanism, the bearing press-fit rotor shaft mechanism, the bearing press-fit pump body mechanism and the bearing retaining ring press-fit pump body mechanism are as follows.

[0016] 1. Oil seal press installation mechanism: including the pump body positioning seat 10, the oil seal pressing head 12 and the moving mechanism, the pump body positioning seat 10 and the mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap