Method and die for improving corrosion resistant performance of pull rod

An anti-corrosion and rod-drawing technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of rod breakage, affecting the safe operation of the line, corrosion and other problems, and achieve the effect of reducing the amount of earthwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

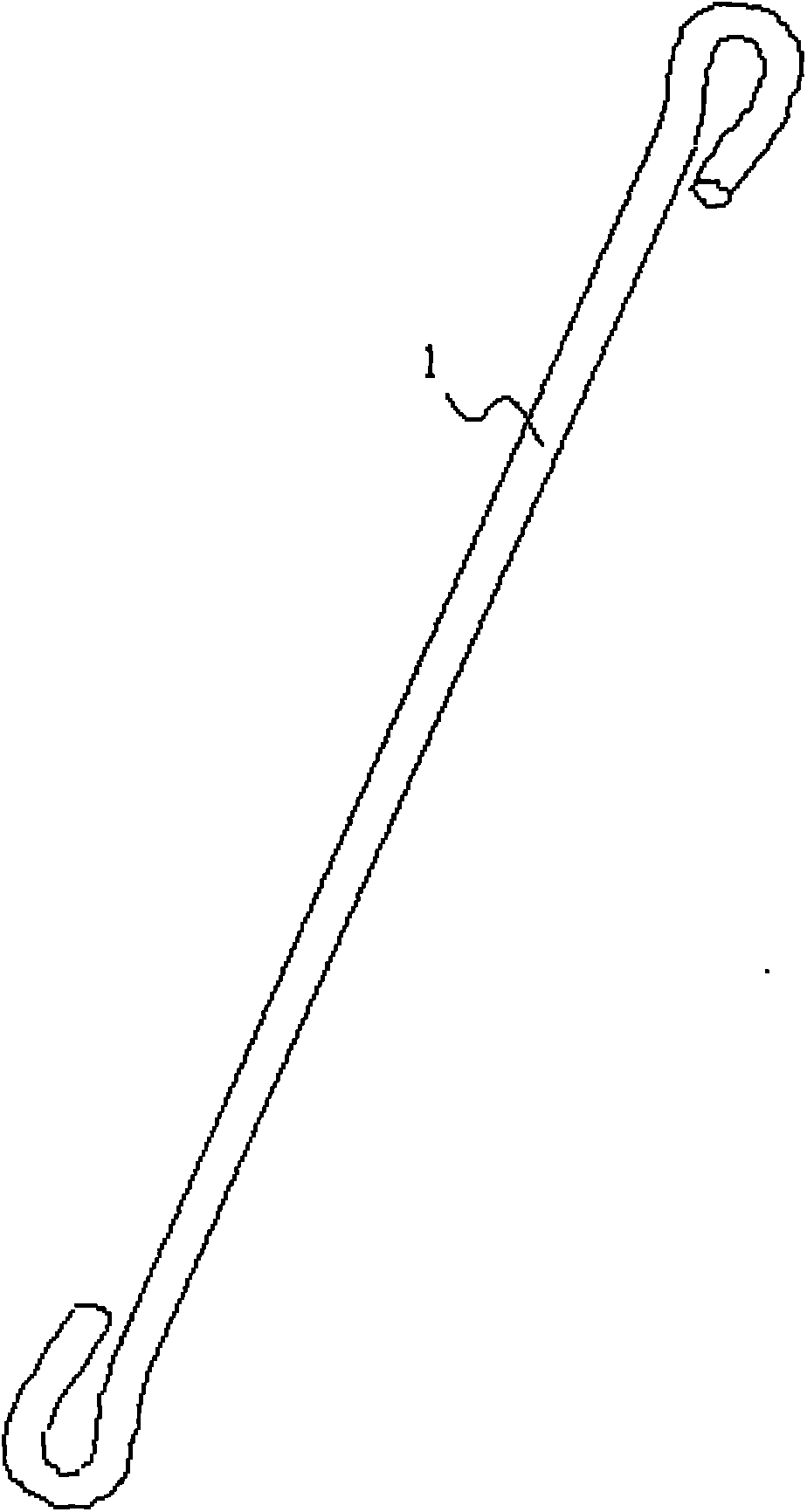

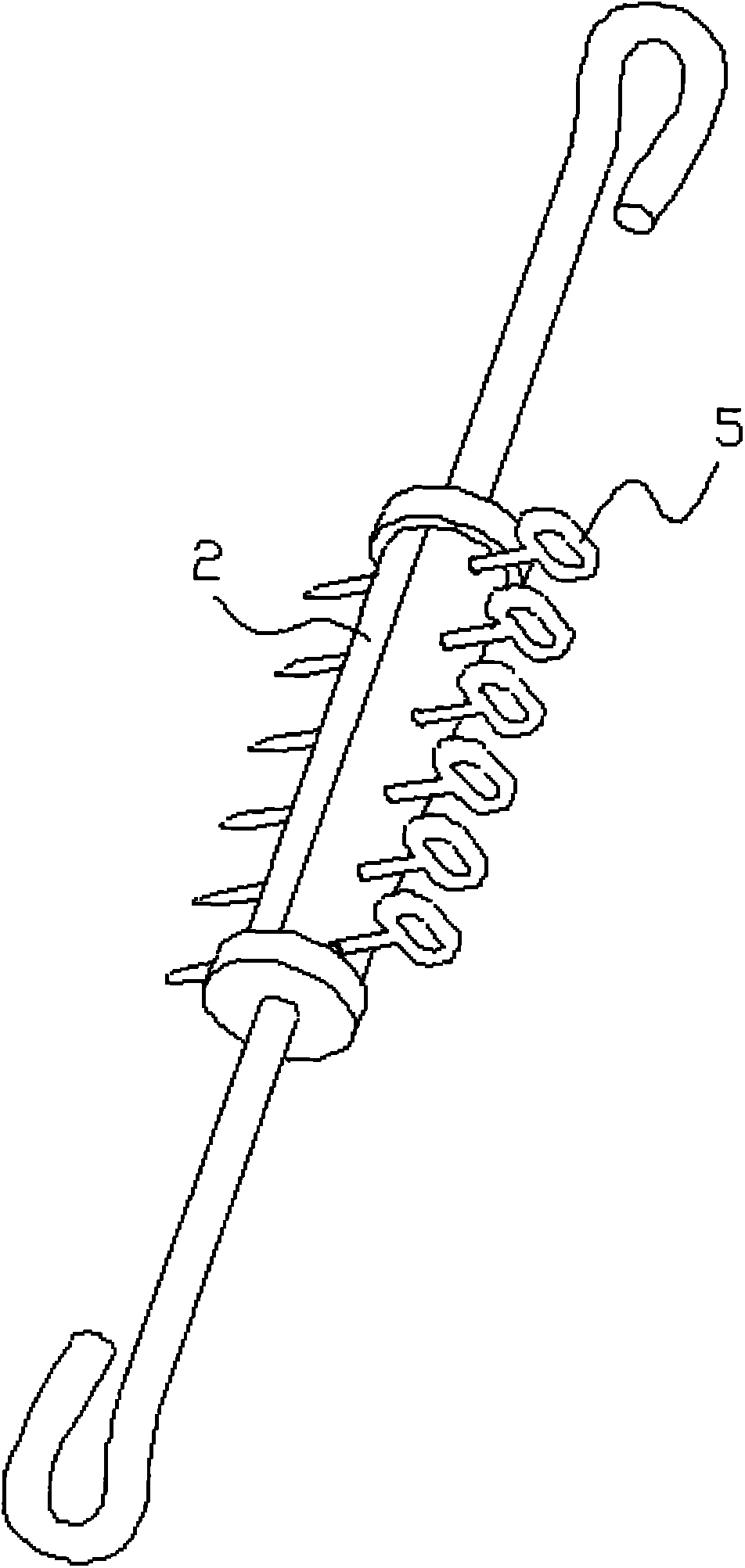

[0029] Such as figure 1 As shown, a method and mold for improving the corrosion resistance performance of the pull rod, the method steps are,

[0030] 1. Mold selection

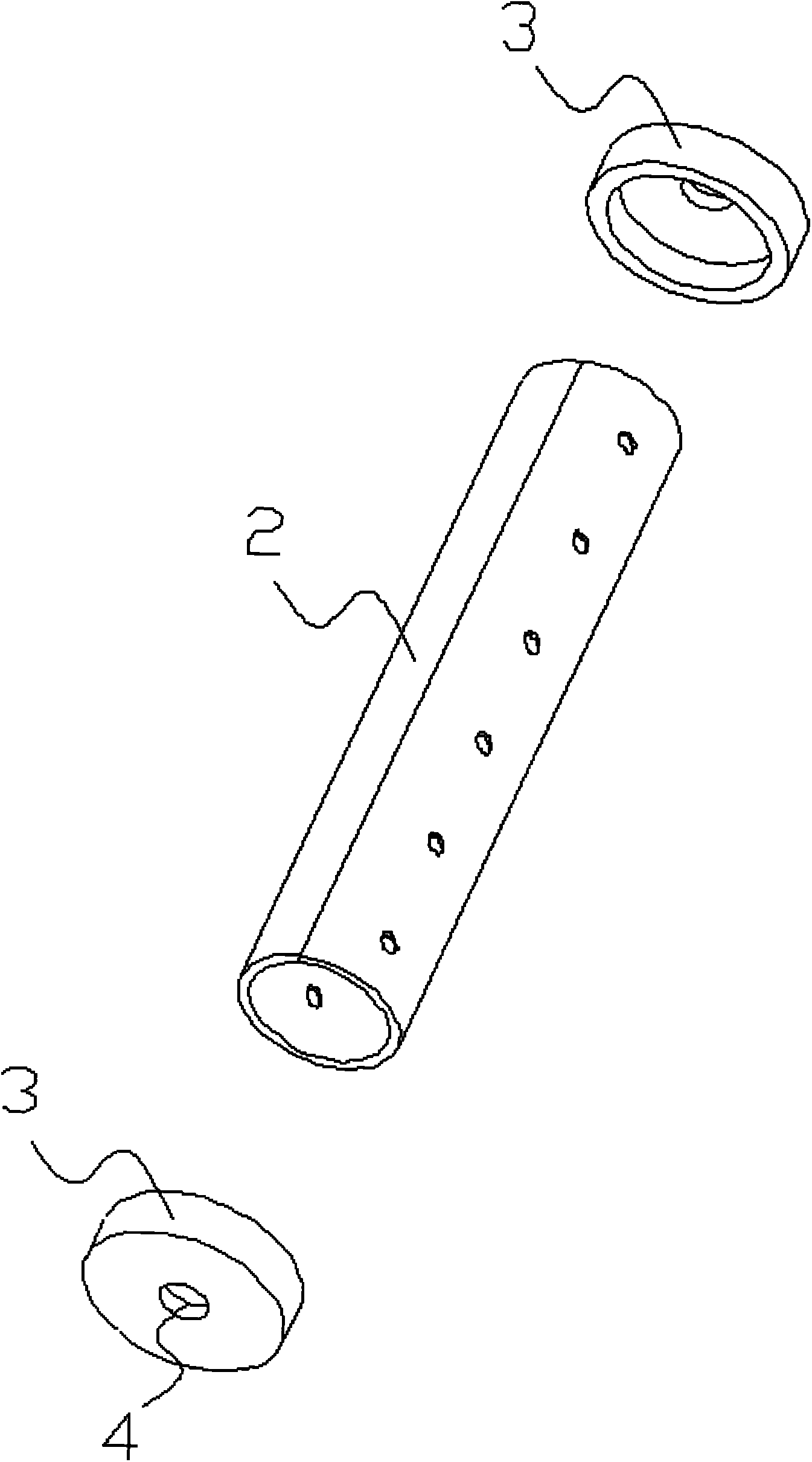

[0031] Such as figure 1 , 2 As shown, the selection length is 50-80cm, the diameter is 75cm, and the cylindrical PVC casing 2 cut longitudinally is provided with a cover 3 at the bottom and top of the casing 2, and a through hole 4 is provided at the center of the cover 3, and the through hole The diameter is the same as that of the pull rod 1;

[0032] 2. Implementation process

[0033] (1) First dig out the soil and check the corrosion layer of the pull rod. If the pull rod is seriously corroded, the pull rod must be replaced;

[0034] (2) Slightly corroded pull rods. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com