Railway eight-axis bathtub open wagon

A bathtub and railway technology, applied in the field of railway freight wagons, can solve the problems of limited vehicle volume and limit the carrying capacity of bathtub-type gondolas, etc., and achieve the effect of high critical speed, good wheel load equalization, and increasing vehicle volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

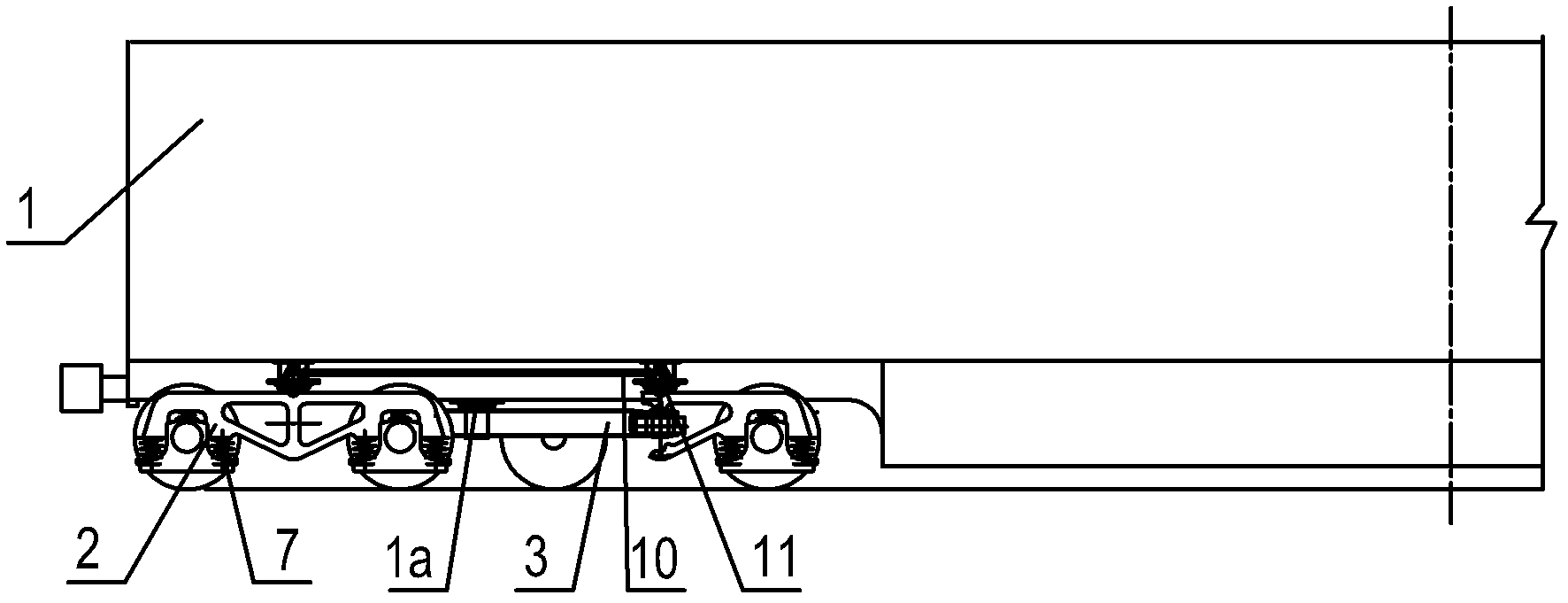

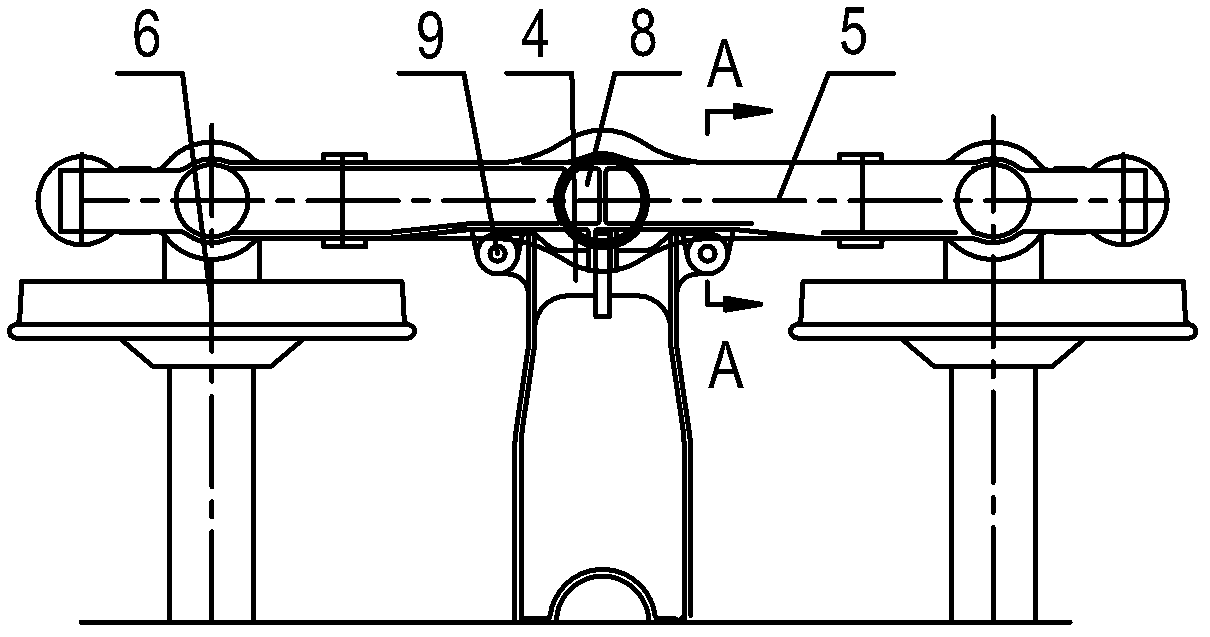

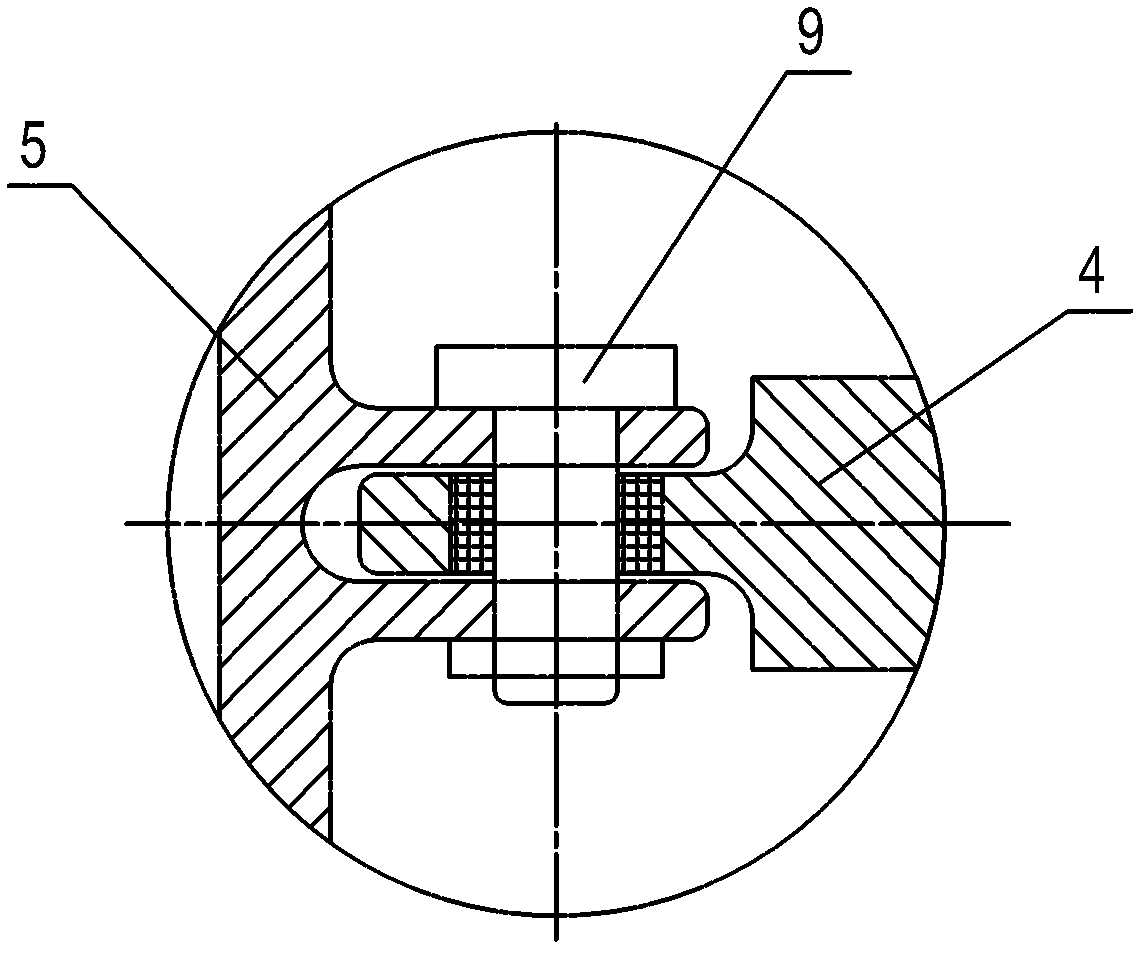

[0018] Such as figure 1 and figure 2 As shown, the railway eight-axis bathtub gondola car of the present invention includes a bathtub-type car body 1, four side-bearing bearing bogies 2 and two sets of side-loading side-bearing systems 10 symmetrically arranged under the front and rear ends of the bathtub-type car body 1. The side bearing bearing type bogie 2 is composed of a center plate beam 4, a side frame 5, a wheel set 6, an axle box spring suspension device 7 and a lower side bearing 8 located on the side frame 5. The two ends of the heart plate beam 4 of the side-bearing bogie 2 are connected with the side frame 5 by vertically installed elastic pins 9 in the horizontal plane, such as image 3 shown. A pitch bolster 3 is arranged between the center beams 4 of the two side bearing bogies 2 at one end of the bathtub type car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com