Intelligent wireless detecting system for longitudinal tearing of conveying belts

A technology of longitudinal tearing and intelligent detection, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as difficult to ensure timely detection of tearing, production troubles, cable laying, maintenance difficulties, etc., to achieve Simple longitudinal tear wireless intelligent detection scheme, quick response, solve the effect of untimely tear fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

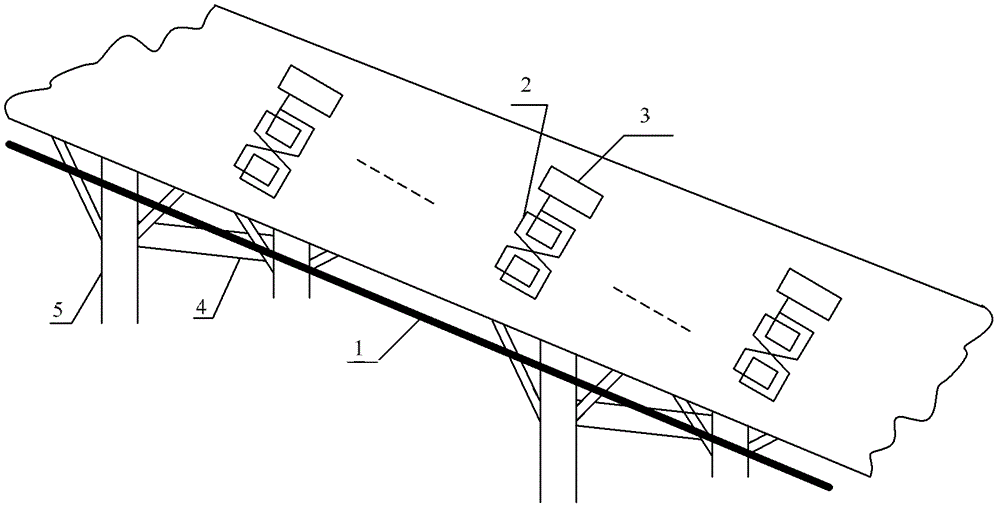

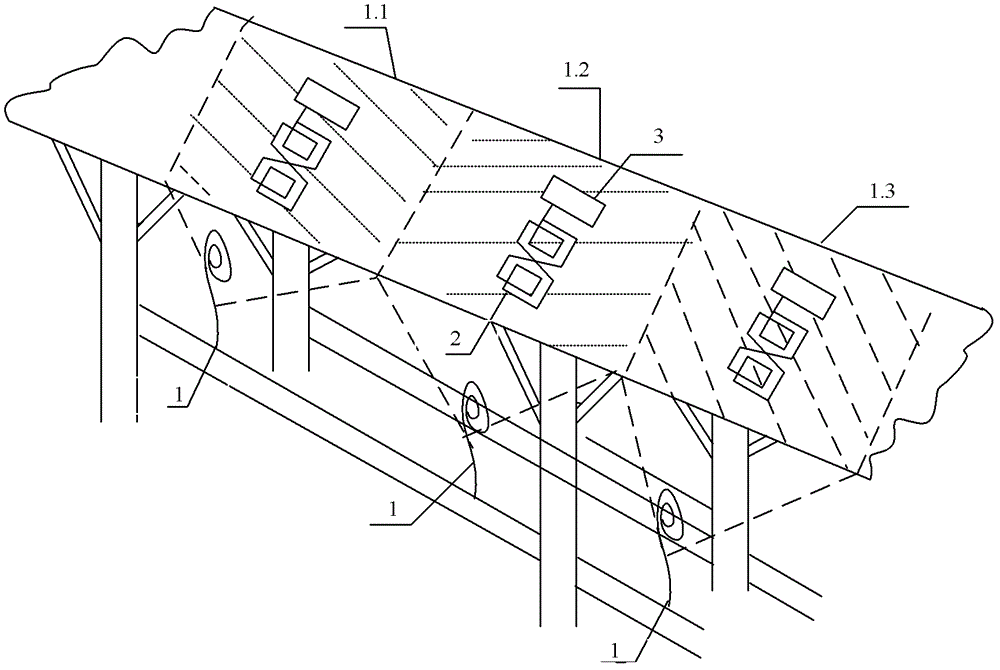

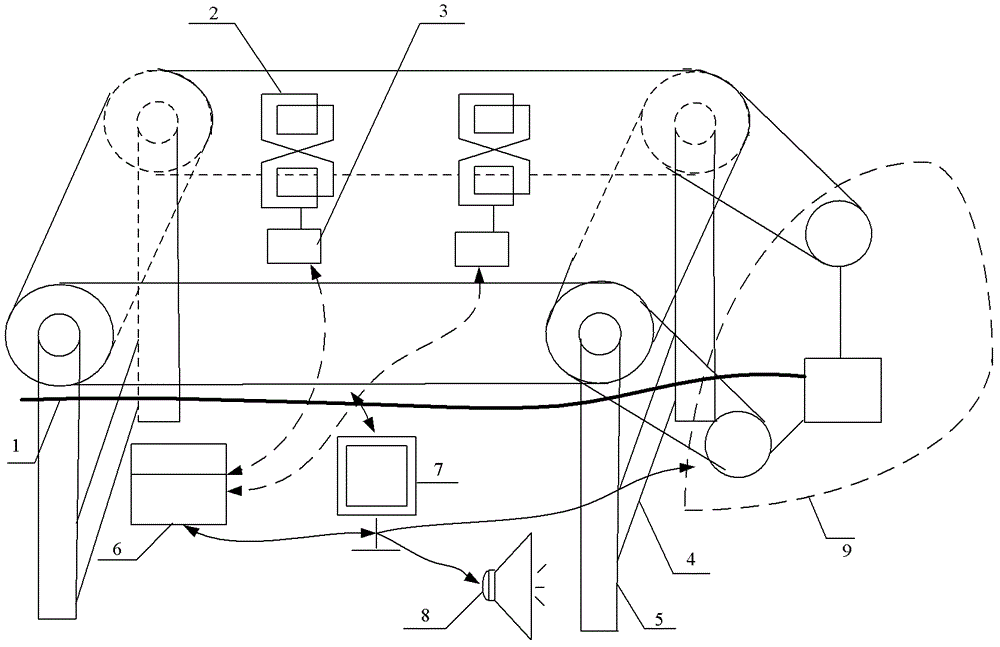

[0016] like figure 1 As shown, the present invention includes external antenna 1, multiple groups of internal antennas 2 and ZigBee modules 3 pre-embedded in the conveyor belt, the external antenna 1 is connected with the conveyor belt motor, laid along the conveyor belt, the power supply of each ZigBee module 3 One or a set of internal antennas 2 are connected to the terminal. The ZigBee module 3 pre-embedded in the conveyor belt has a film-shaped structure and good flexibility, and will not be damaged naturally due to folding. The internal storage module of the ZigBee module 3 is used to record the conveyor belt position number, production date, and conveyor belt accumulation. Effective information such as normal working time and damage time. When the conveyor belt motor is working normally, the external antenna 1 converts the transmitted electric energy into electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com