Horizontal lifting mechanism applied to medium and large shells

A large and medium-sized, horizontal technology, used in lifting devices, metal processing, metal processing equipment, etc., to achieve the effect of efficient and stable lifting process, simple and reliable control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

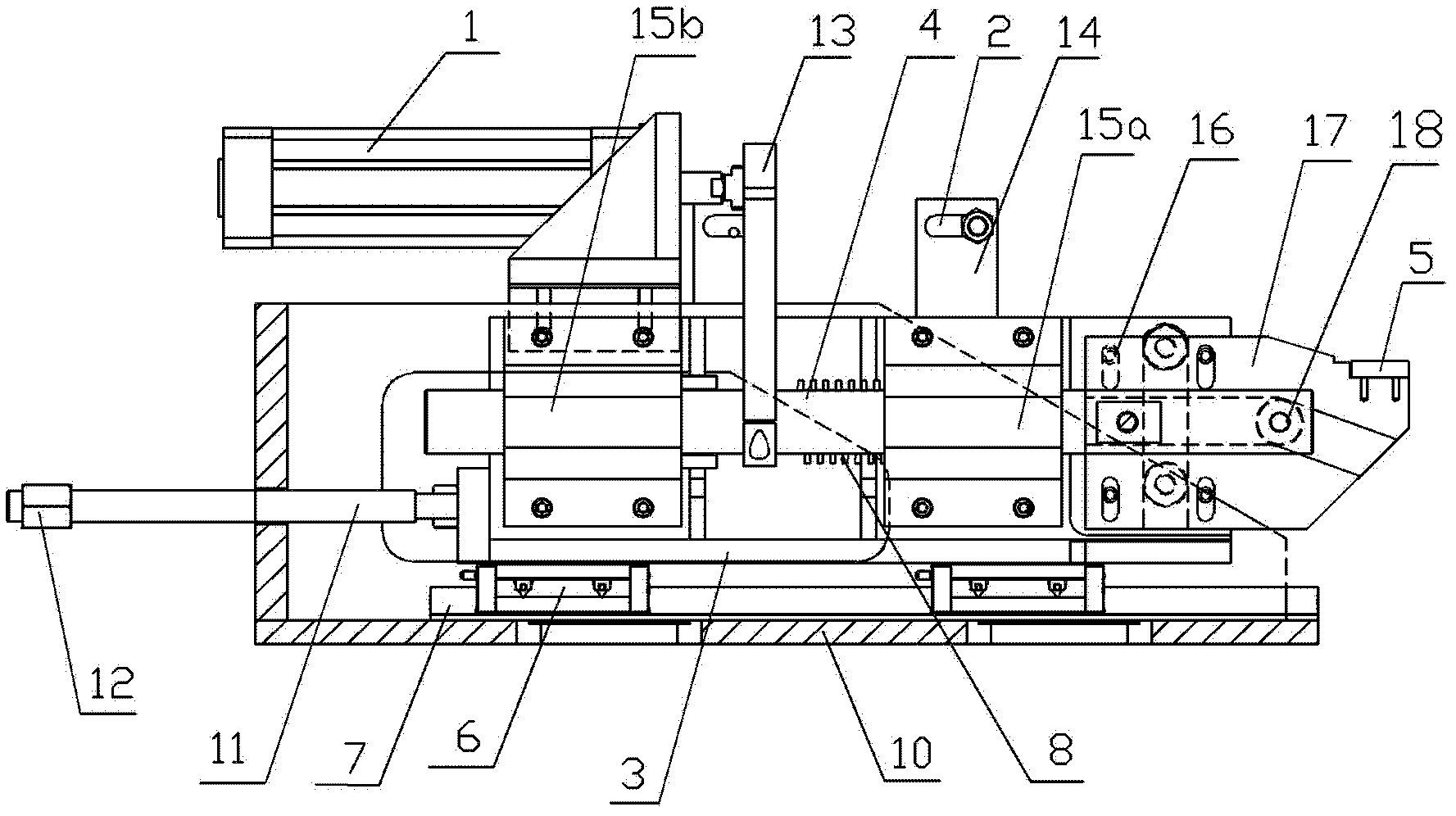

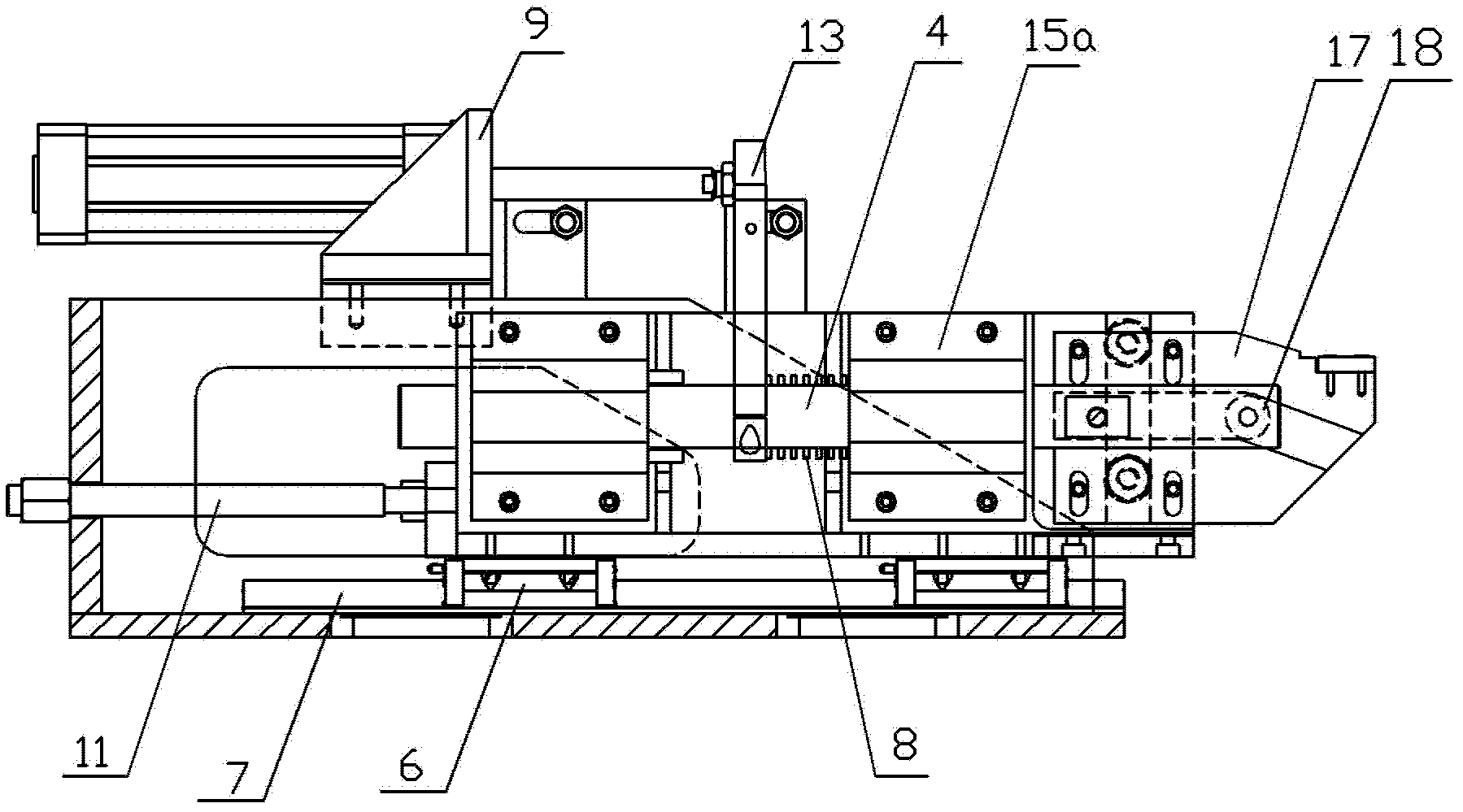

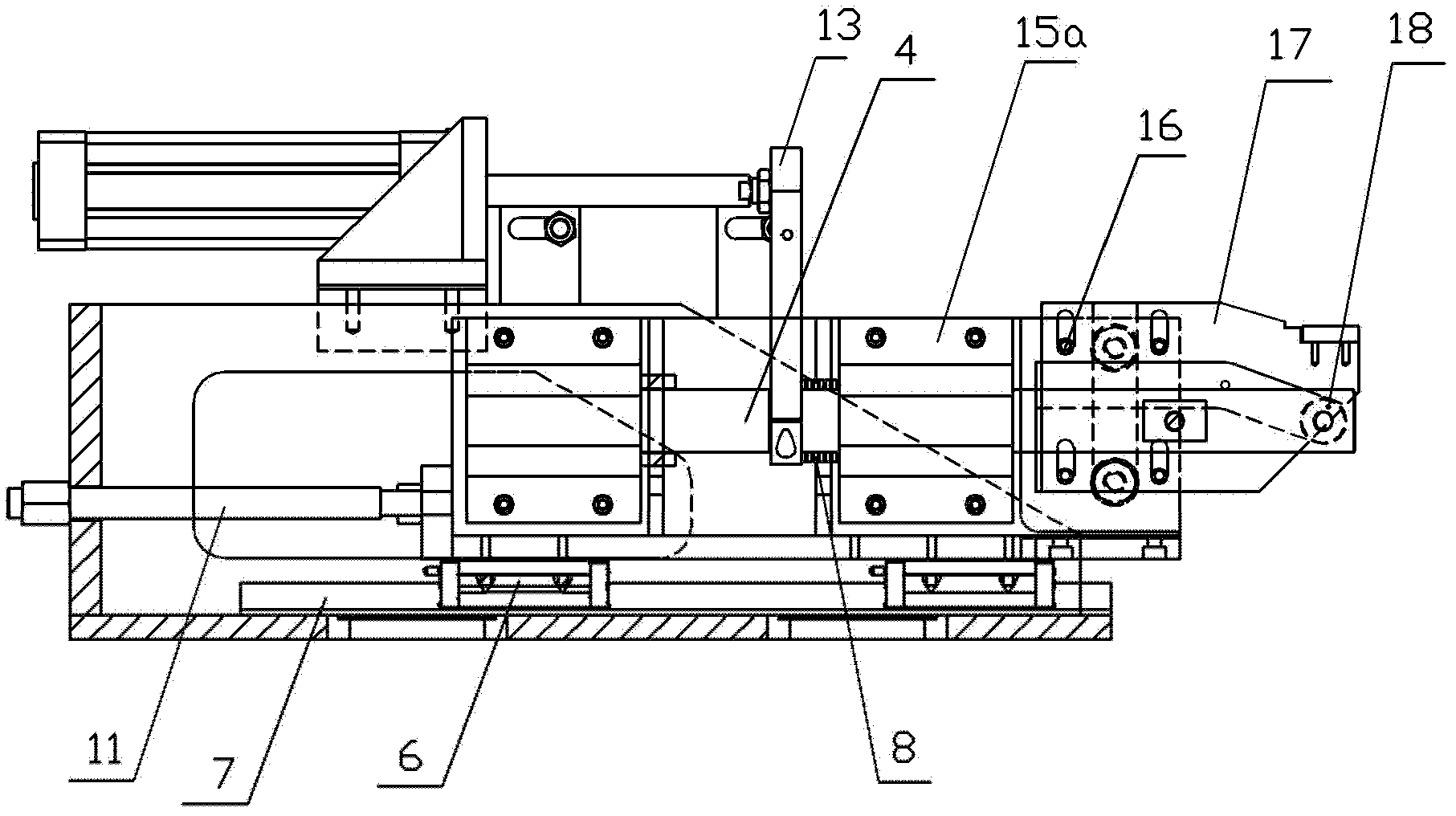

[0021] see figure 1 , the characteristics of the horizontal lifting mechanism applied to large and medium-sized casings in this embodiment are:

[0022] A jacking cylinder 1 is fixedly arranged on the top of the frame 3 with its cylinder support 9, and its cylinder rod is horizontally arranged. One end of the longitudinal connecting rod 13 is connected to the rod end of the cylinder rod, and the other end is fixed with the horizontal push rod 4. Connected, the horizontal push rod 4 is arranged in parallel with the cylinder rod;

[0023] A support block 17 as a lifting platform is positioned at the front end of the horizontal push rod 4, and slides and fits along the vertical direction between the frame 3 and the support block 17; It is composed of a section of linear guide slideway arranged in a direction parallel to the horizontal push rod 4 and a section of inclined downward jacking slideway connected to the front end of the linear guide slideway; Lifting bearing 18 fits i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com