Adjusting shaft arrangement of a turbocharger

A technology of turbocharger and shaft adjustment, applied in the direction of machine/engine, engine manufacturing, combustion engine, etc., can solve the problem of reducing the length of the gap seal, and achieve the effect of reducing exhaust gas and smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

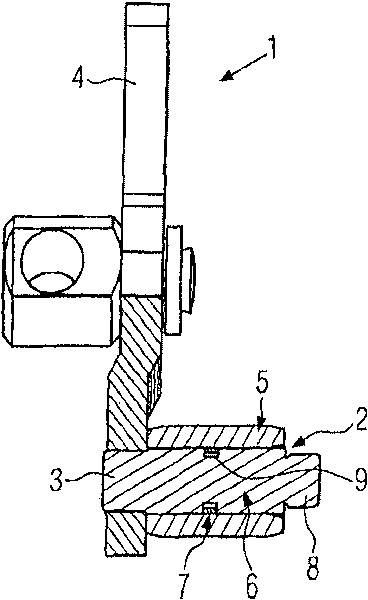

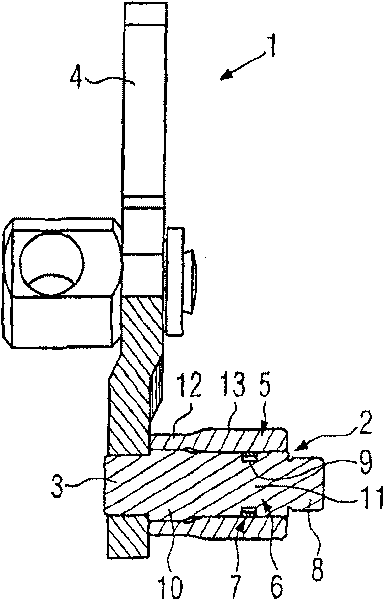

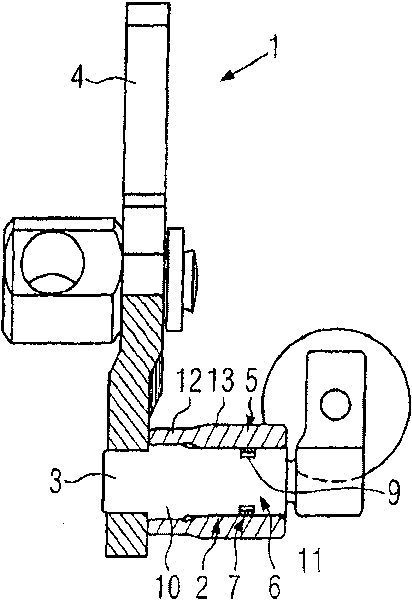

[0016] FIG. 1 shows a known adjusting shaft arrangement 1 of a VTG turbocharger. The VTG turbocharger itself is not shown in further detail in the figure, since this may comprise a conventional construction known per se.

[0017] The adjusting shaft arrangement 1 has an adjusting shaft 2 comprising a fixed part 3 and a free end 8 . Furthermore, FIG. 1 shows that the outer diameter of the fixed part 3 and the free end 8 is smaller than the main body 6 of the adjustment shaft 2 , said main body 6 being arranged between the fixed part 3 and the free end 8 . In this example all three parts have a cylindrical outer contour.

[0018] The adjusting shaft 2 is connected to a rod 4 via a fastening part 3 .

[0019] Furthermore, the adjusting shaft arrangement 1 has a bushing 5 which is arranged on the basic body 6 of the adjusting shaft.

[0020] Finally, a seal 7 is provided, which is arranged on the base body 6 between the bushing 5 and the adjustment shaft 2 . For this purpose, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com