Apparatus and method used for preparing graphene, and obtained graphene

A technology of graphene film and furnace tube, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems that cannot meet large-scale production and affect the output of graphene film, and achieve the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the present invention, the term "sample" used refers to the base material sample itself or the base material sample with dragging parts used to support the growth of the graphene film.

[0024] The term "growth gas" or "growth gas source" as used herein refers to the gas used to grow the graphene film.

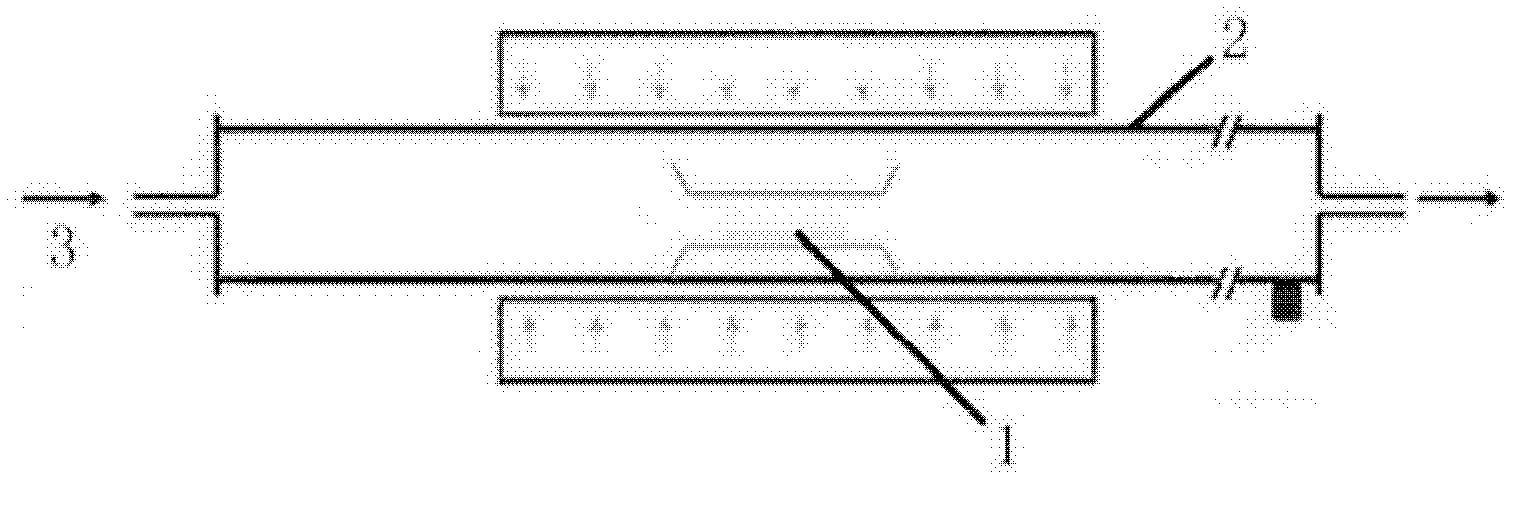

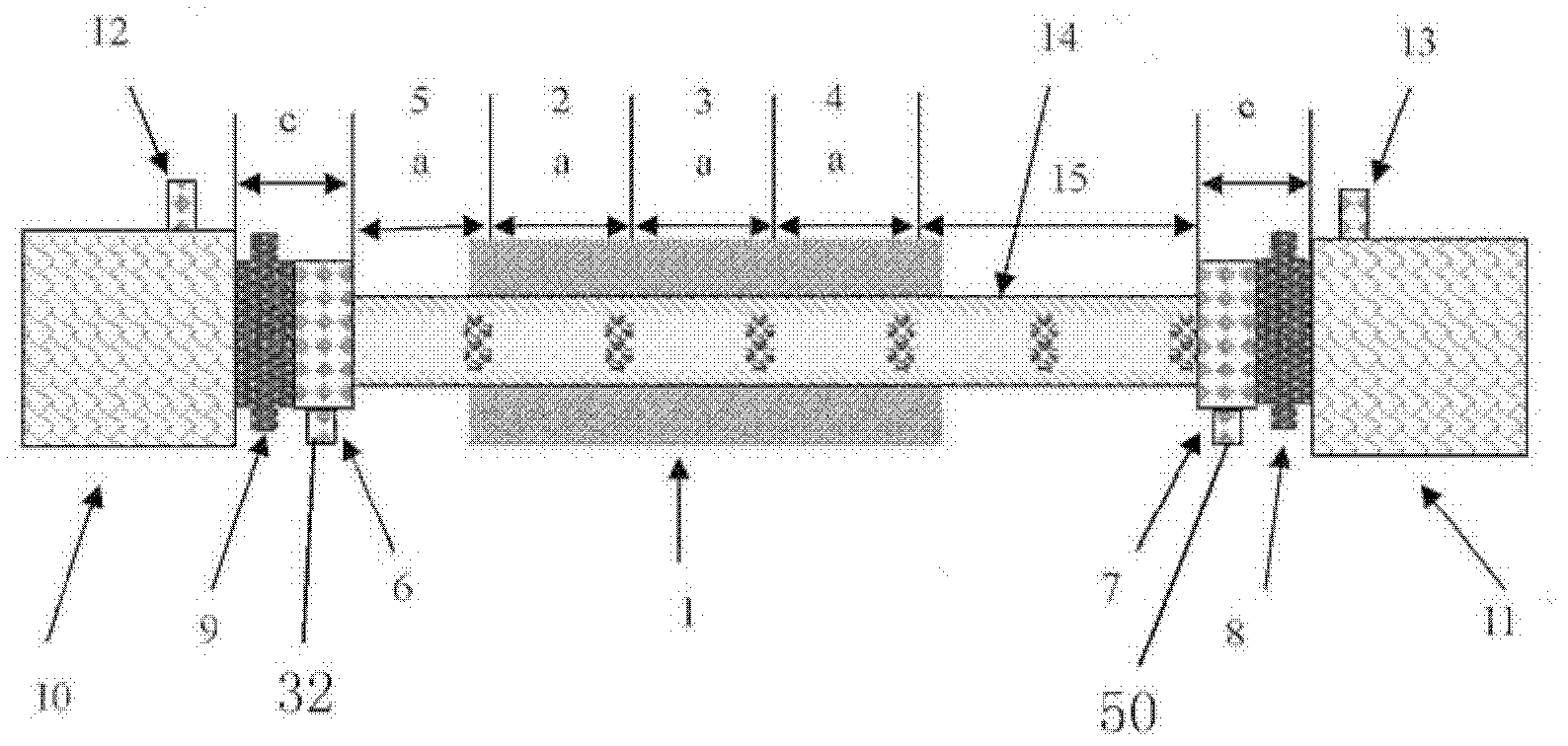

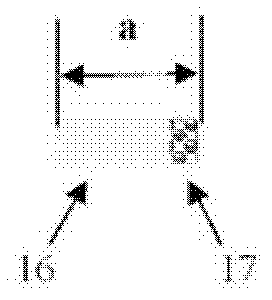

[0025] The invention provides a device for continuously preparing graphene films, which comprises a furnace tube with openings at both ends, and the openings at both ends are respectively connected with an opening end of a sampling chamber and an opening end of a sampling chamber, wherein A valve and an air inlet interface part are provided at the connection between the furnace tube and the sample chamber, a valve and an air outlet interface part are provided at the connection between the furnace pipe and the sample chamber, and the sample chamber is also equipped with an inlet A gas inlet / outlet interface part and a sample inlet, and the sample outlet chamber is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com