Non-blasting construction method for dismantling pier to land bridge

A construction method and non-blasting technology, applied in building maintenance, construction, building construction, etc., can solve the problems of small working surface of the main body of the cutting bridge, high work risk factor, unfavorable construction safety, etc., and achieve compact and operable construction procedures. The effect of good performance and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

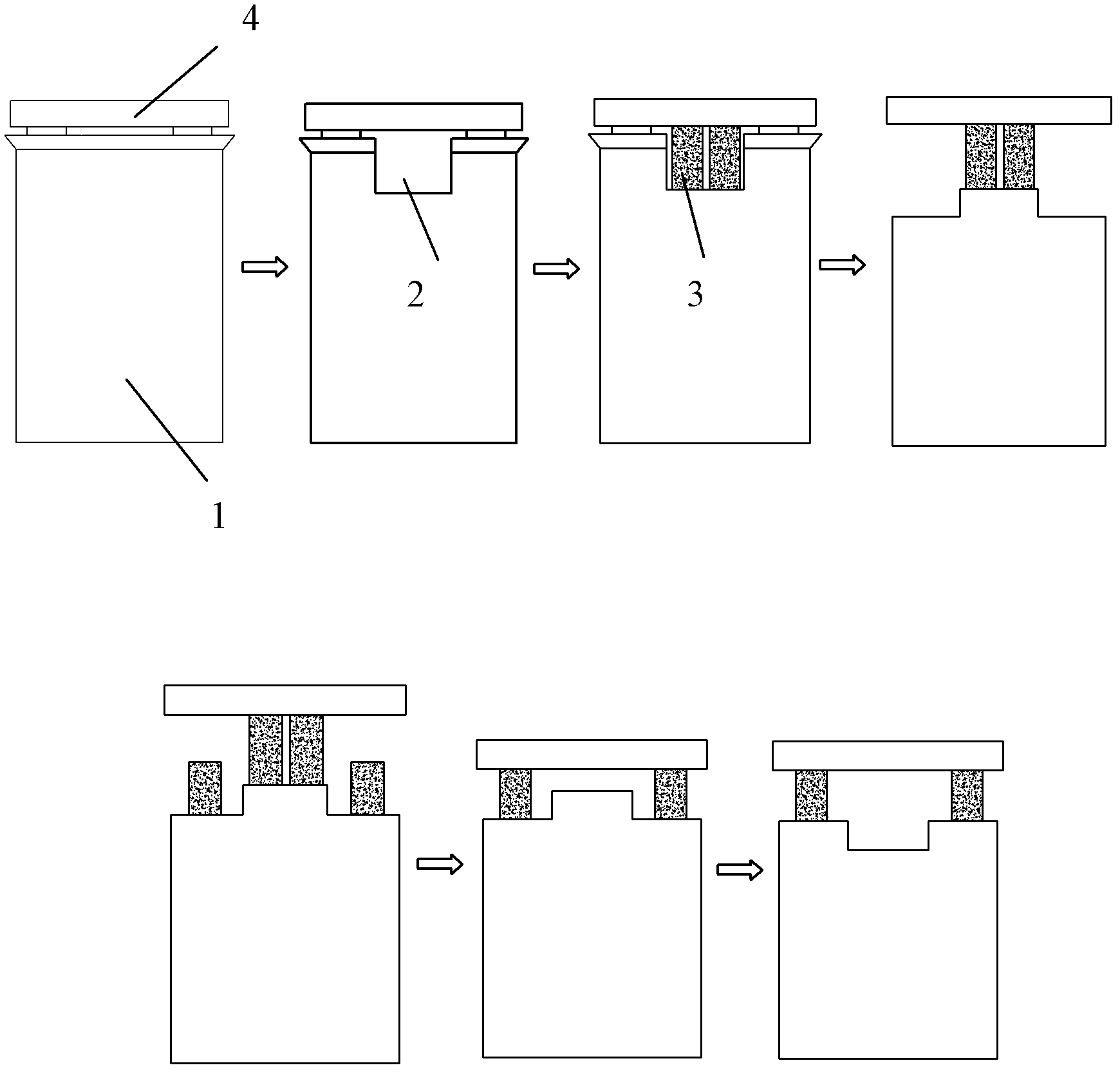

[0015] The construction method of non-explosive demolition of bridge piers provided by the present invention to make the bridge land on the ground will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 Shown, the non-explosive demolition bridge pier provided by the present invention makes the construction method of bridge landing comprise the following steps carried out in order:

[0017] 1) Firstly, a gap 2 is formed through the middle position of the side top of the pier 1 by the staff using a crushing machine;

[0018] 2) Fill the gap 2 with a temporary sandbag support 3, and make the upper end of the temporary sandbag support 3 close to the bottom surface of the main beam 4;

[0019] 3) Remove the top structure of the pier 1 located on both sides of the temporary sandbag support 3, and the removal height is greater than the height of the temporary sandbag support 3. When removing the two sides, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com