Steel tube column capable of preventing concrete spillover and method for mounting steel tube column

An installation method and a steel pipe column technology, which are applied in the field of steel pipe columns, can solve the problems of concrete waste, labor-intensive removal, etc., and achieve the effects of shortening construction time, simple and easy installation method, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

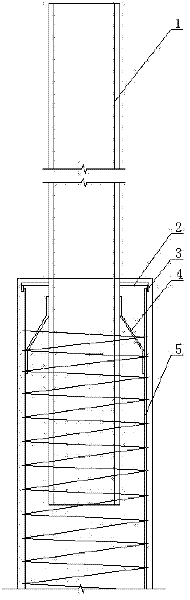

[0022] A steel pipe column for preventing concrete spillage, comprising a steel pipe column 1, and a circular steel plate 2 coaxially fixed on the outer wall of the steel pipe column. An integral ring steel plate is inserted into the outer wall of the steel pipe column, a connecting steel ring 3 is fixed vertically downward on the circumference of the ring steel plate, and connecting steel bars 4 are evenly distributed and fixed on the outer wall of the steel pipe column below the ring steel plate , Observation hole 6 is formed on the ring steel plate.

[0023] A method for installing a steel pipe column for preventing concrete overflow, the steps of the method are:

[0024] (1) At the lower part of the steel pipe column, a circular steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com