Wall moisture exhausting system

A technology of moisture removal system and exhaust system, which is applied in the direction of architecture and building structure, and can solve problems such as falling off of decorative panels, loss of effect of adhesive layer connecting decorative panels, and powdery exterior walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

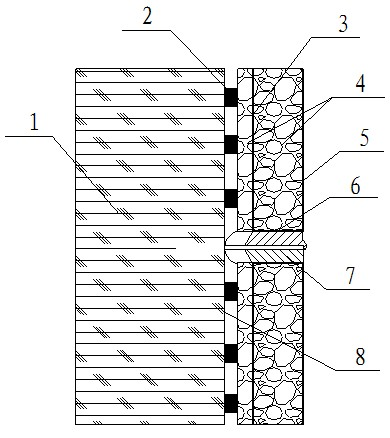

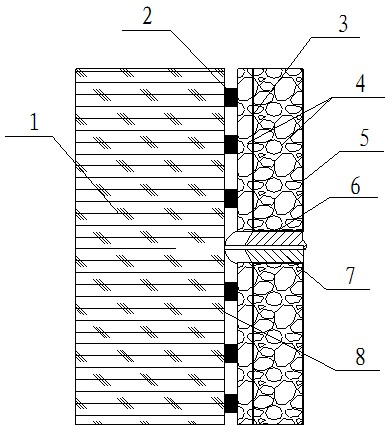

[0011] figure 1 A wall moisture removal system shown mainly includes a base wall surface 1 and a plastering layer 8, the outer layer of the plastering layer 8 is connected with an insulating board 4 through an adhesive 2, and the outer layer of the insulating board 4 is covered with a decorative board 5, It is characterized in that an exhaust system consisting of an exhaust plug 7 and a sealant 6 is installed in the gap between two adjacent insulation boards 4, and the adhesive 2 is bonded to the plastering layer 8 at intervals with a distance of 4 cm. ~7cm, insert the reinforced aluminum plate 3 at one-third to one-half of the insulation board 4, the effect is to enhance the bonding strength. The external steam generated inside the wall is discharged along the exhaust port of the exhaust plug 7 in the gap of the wall, so that the wall can automatically absorb the internal gas and discharge it into the air, achieving the effect of "automatic breathing" and keeping the wall Dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com