Method of adopting tool type clamp to support ground beam template side molds

A tool-type, ground-beam technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems such as the tightness of extrusion between the formwork that cannot meet the control accuracy of beam section size, and achieves The effect of high recyclability, high turnover and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

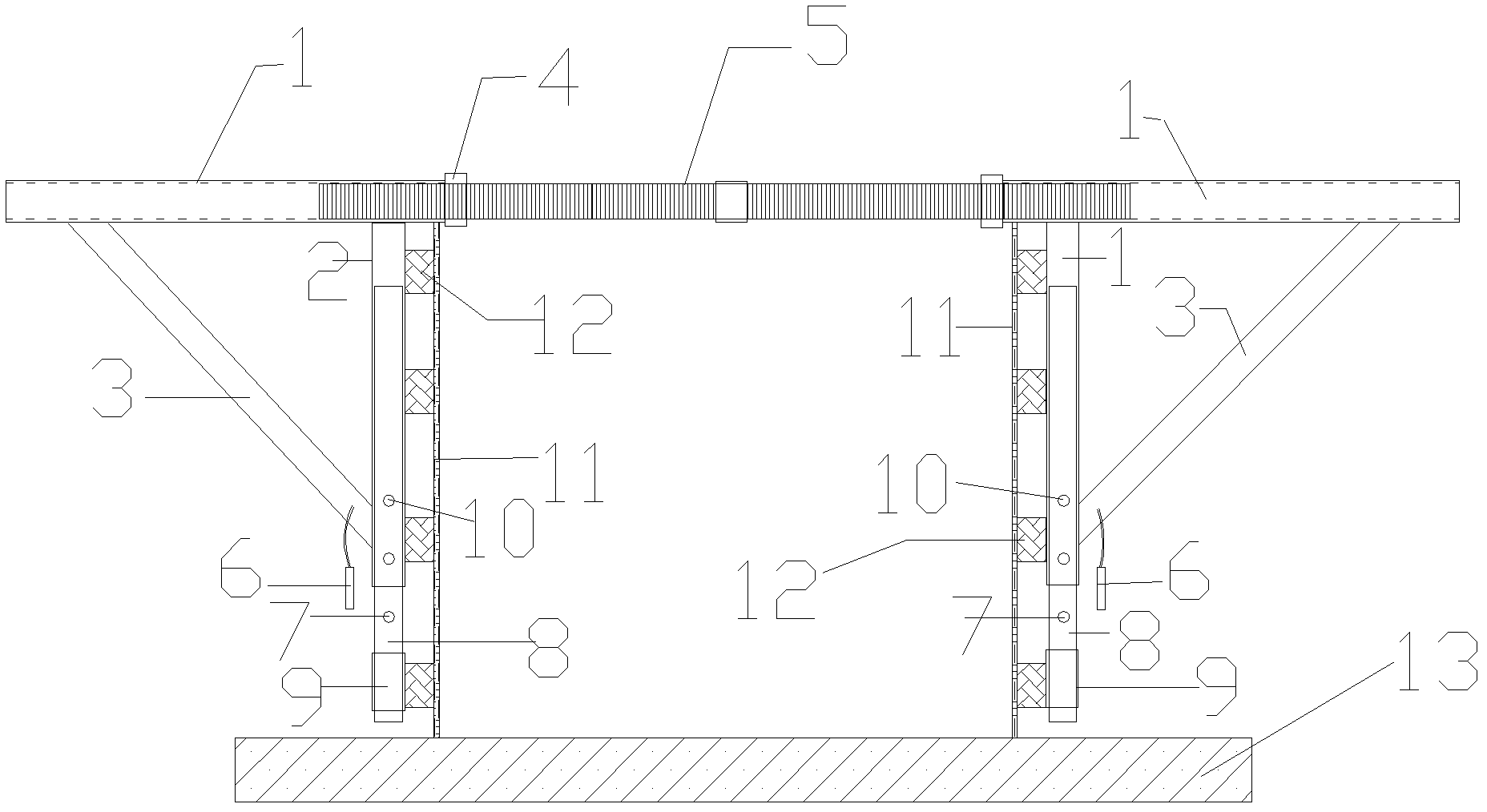

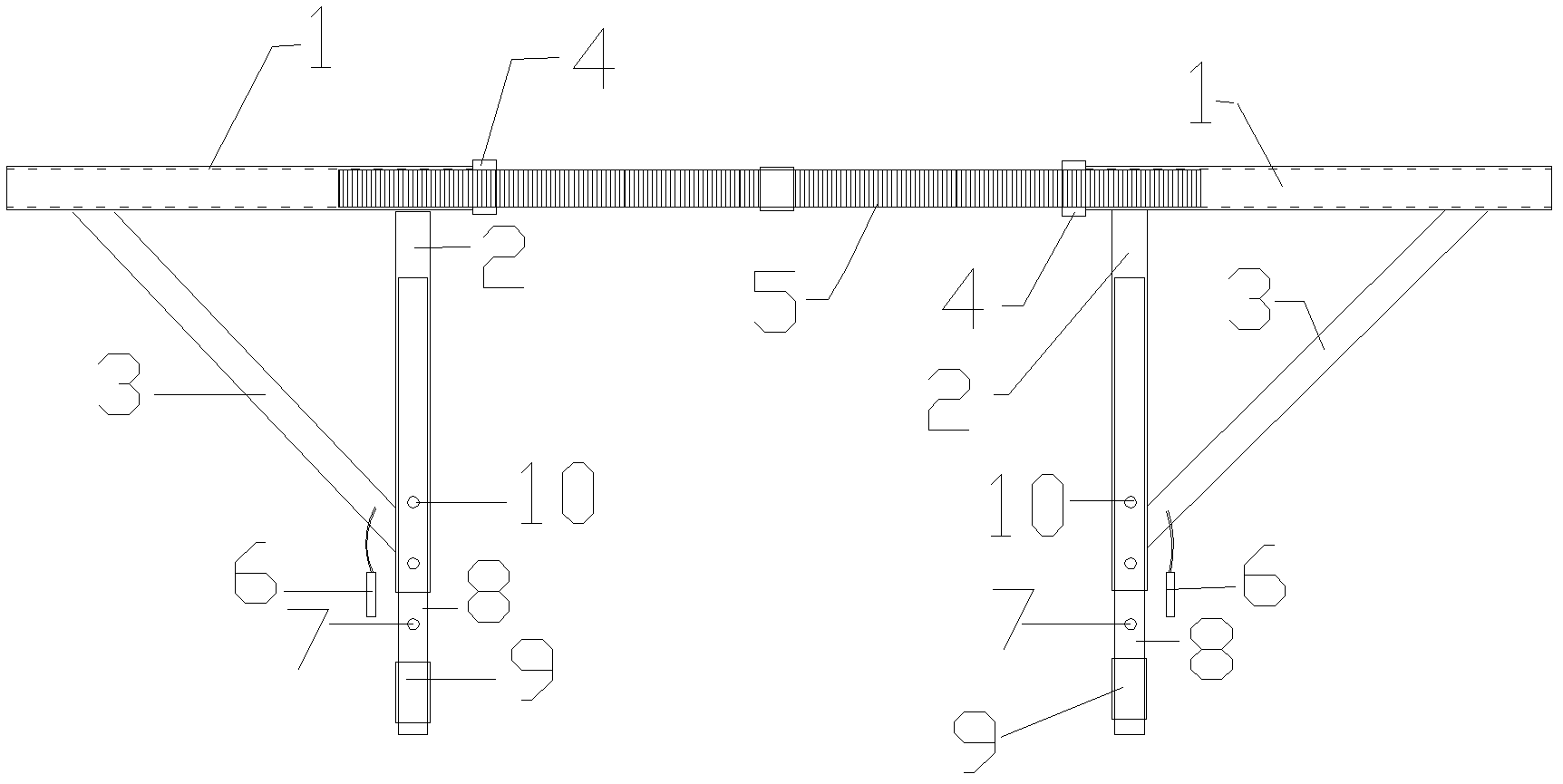

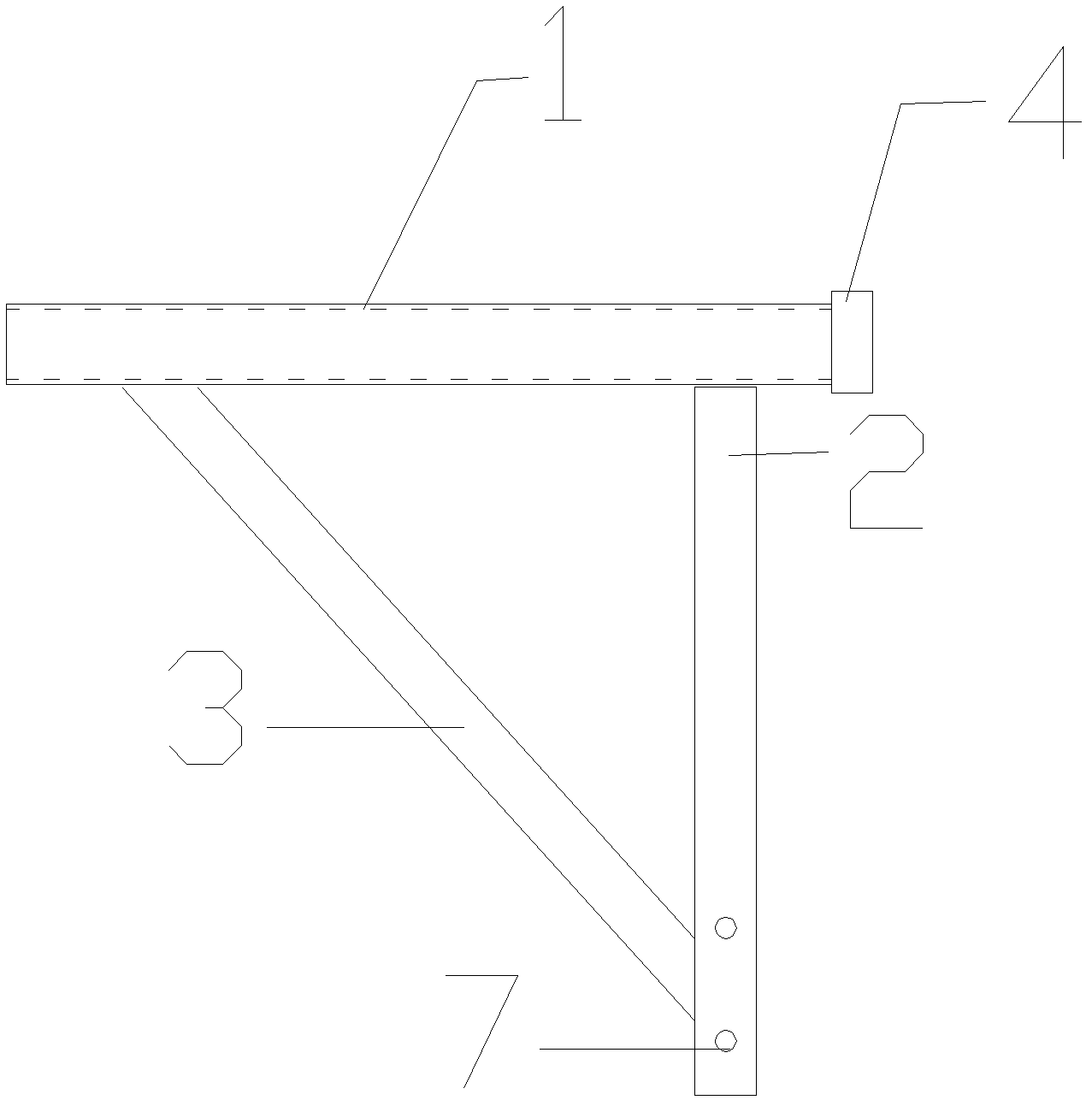

[0026] According to the size of the ground beam, select a fixed tripod consisting of horizontal 1, longitudinal rod 2, diagonal rod 3 and nut 4 suitable for the height of the ground beam, and select a screw 5 of appropriate length according to the width of the ground beam. The sliding rod 8 of the adjusting rod is inserted into the longitudinal rod 2 of the fixed tripod and assembled with the positioning pin 6 as a whole, and the screw rod 5 is connected with the two nuts 4 of the fixed tripod and the inner wire of the horizontal 2 to form the fixture of the invention.

[0027] Use the above fixtures for construction:

[0028] (a) The two side molds 11 of the ground beam provided with the outer longitudinal ribs 12 are erected on the ground mold 13 according to the ground beam positioning line; (b) The screw 5 of the fixture is installed on the top of the ground beam side mold and The two longitudinal rods of the fixture are respectively arranged outside the outer longitudinal corr...

Embodiment 2

[0031] According to the size of the ground beam, a stereotyped fixed tripod consisting of horizontal 1, longitudinal rod 2, diagonal rod 3 and nut 4 was selected to suit the height of the ground beam, and the screw 5 of appropriate length was selected according to the width of the ground beam. The sliding rod 8 of the adjusting rod is inserted into the longitudinal rod 2 of the fixed tripod and assembled with the positioning pin 6 as a whole, and the screw rod 5 is connected with the two nuts 4 of the fixed tripod and the inner wire of the horizontal 2 to form the fixture of the invention.

[0032] Use the above fixtures for construction:

[0033] (a) The two side molds 11 of the ground beam provided with the outer longitudinal ribs 12 are erected on the ground mold 13 according to the ground beam positioning line; (b) The screw 5 of the fixture is installed on the top of the ground beam side mold and The two longitudinal rods of the fixture are respectively arranged outside the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com