High-intensity retractable support

A high-strength, U-shaped technology, used in pillars/supports, mining equipment, earth-moving drilling, etc., can solve problems such as poor stability, breakage, and variability of incoming pressure, reducing support density, easy to operate, and not easy to be damaged. pull-out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

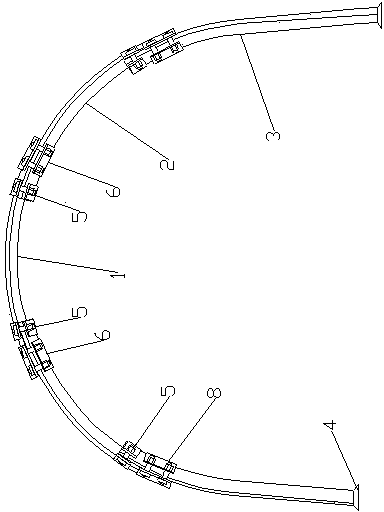

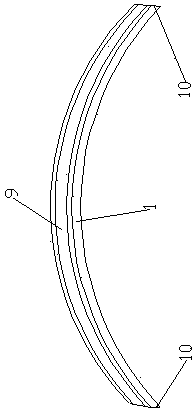

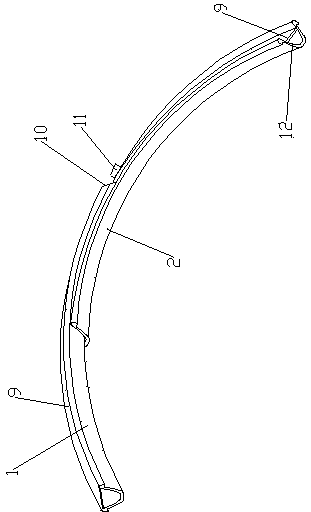

[0026] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, and 14, a high-strength retractable support includes a column shoe 4 and a U-shaped shed installed above the column shoe 4 Leg 3, U-shaped side beam 2 installed on the upper part of U-shaped shed leg 3, U-shaped middle beam 1 installed above U-shaped side beam 2, U-shaped middle beam 1, U-shaped side beam 2 and U-shaped side The bracket 5 between the beam 2 and the U-shaped shed leg 3, the upper part of the U-shaped middle beam 1, the U-shaped side beam 2 and the U-shaped shed leg 3 are all fixedly installed with an upper bottom plate 9, and the U-shaped Both ends of the middle beam 1 are provided with a middle beam slope 10, the bottom of the U-shaped side beam 2 is provided with a side beam slope 12, and the upper end of the U-shaped side beam 2 is provided with a gap 13 on the upper part of the side beam. The upper end of the shed leg 3 is provided with a notch 15 on the upper part of the shed leg, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com