Flat-plate solar heat collector

A solar heat collector, flat-plate technology, applied to solar heat collectors, solar heat collectors using working fluid, solar thermal energy, etc., can solve the problem of loss, large radiation heat loss, and large temperature difference between the inner surface and the heat-absorbing surface and other problems, to achieve the effect of reducing loss and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

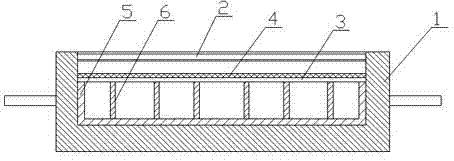

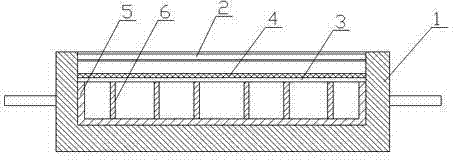

[0012] see figure 1 , a flat-plate solar heat collector, comprising an outer frame 1, a transparent material plate 2, and an insulating layer 5, the transparent material plate 2 is a transparent glass plate with a vacuum interlayer, and a heat absorbing plate is arranged below the transparent material plate 2 Plate 3, the upper surface of the heat absorbing plate 3 is coated with a heat absorbing coating 4, the heat absorbing plate 3 is made of ceramics, the heat absorbing coating 4 is a black coating or a selective absorbing film, heat preservation The layer 5 is arranged on the inner surface of the outer frame 1 below the heat absorbing plate 3, and the two sides of the outer frame 1 are respectively connected with water inlet pipes and water outlet pipes. The thermal partition 6, the heat storage partition 6 is made of purple sand material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com