Patents

Literature

30results about How to "Good thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

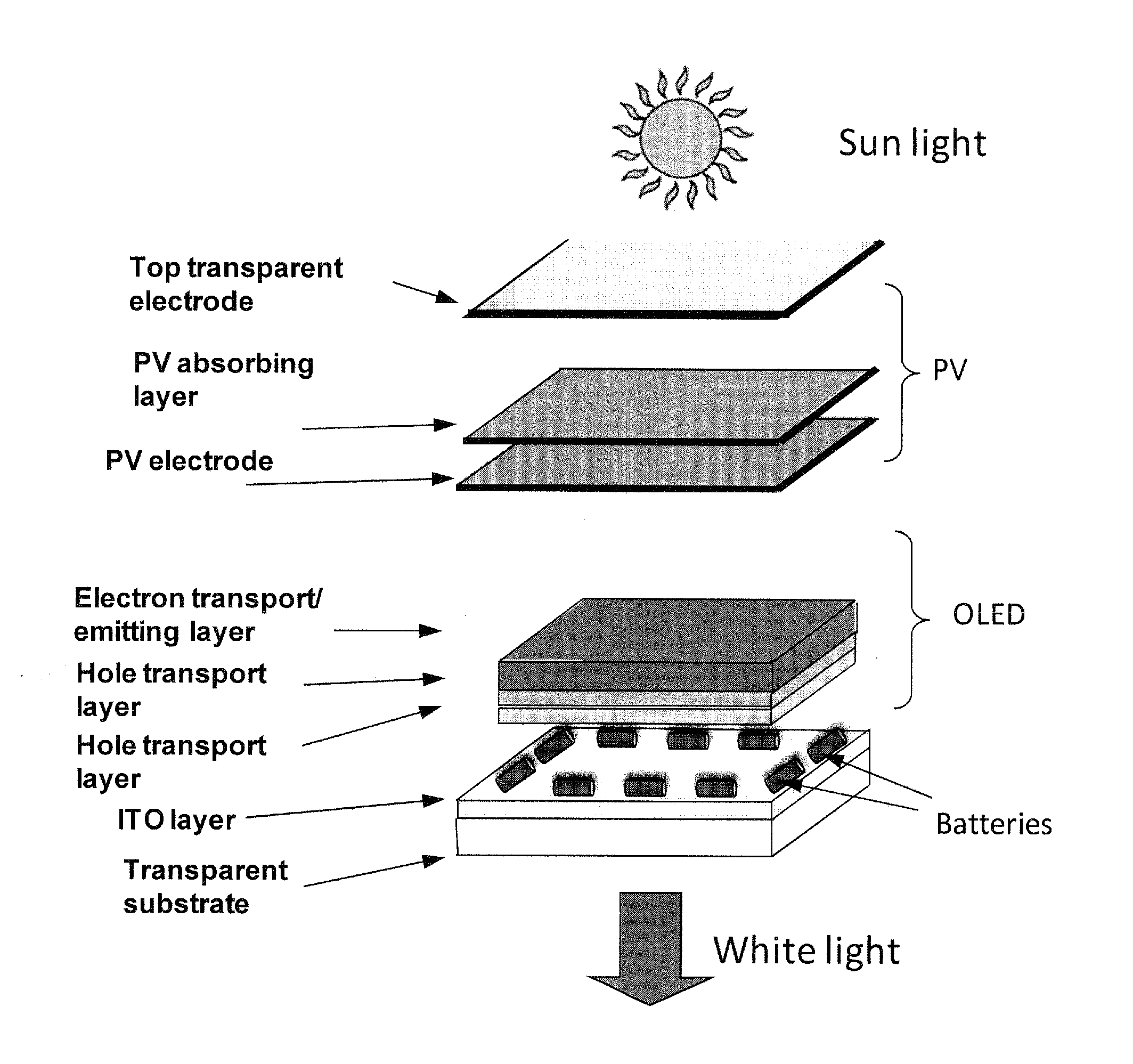

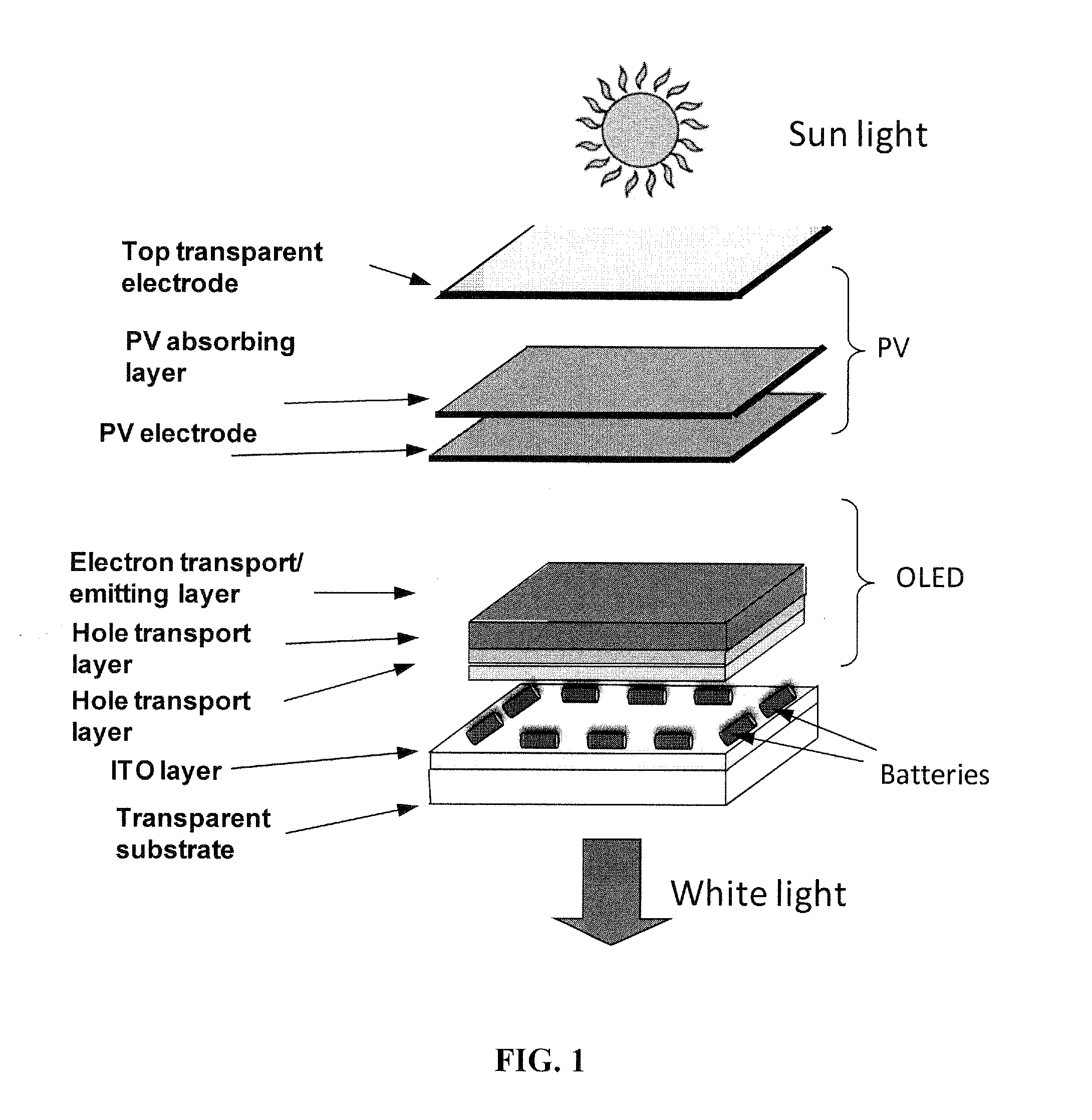

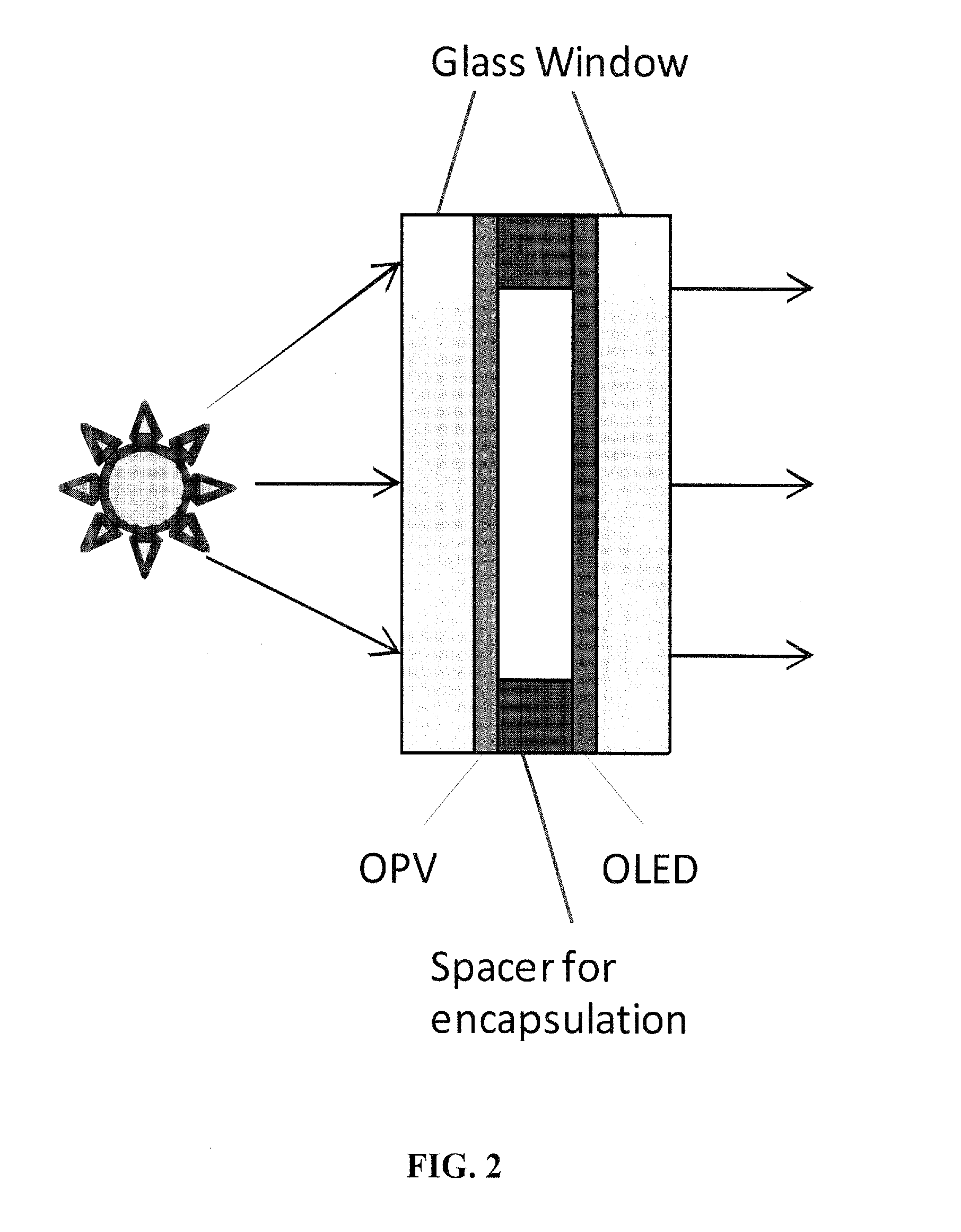

Solar-powered lighting module

ActiveUS20120120643A1Good thermal insulationLow transmissionNanoinformaticsSolid-state devicesElectrical batteryElectricity

A solar-powered lighting module is provided, including a solar cell for generating electricity when exposed to light, a battery for storing charge from the generated electricity, and a light generating device powered by the stored charge. In an embodiment, the module further includes a controller that regulates the current transmitted between the components of the module. In a further embodiment, the module is incorporated into an interface to an environmentally controlled space and can be positioned to light an interior portion of the space. In another embodiment, the solar cell and light generating device are transparent to allow light to pass through the interface. In a further embodiment, tinted-color conjugated polymers incorporated into the module limit the spectrum of light that can pass through the interface. In yet another embodiment, a method of modifying an existing interface with such a module is provided.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Glass wool ceiling board and preparation method thereof

ActiveCN104652745AGood sound absorptionGood thermal insulationGlass making apparatusCovering/liningsGypsumWool

The invention discloses a glass wool ceiling board. The glass wool ceiling board comprises a glass wool board layer, a glass fiber felt layer and a plaster coating material layer, wherein the glass wool board layer is prepared from centrifugal glass wool fibers with an environment-friendly resin binder, and the mass ratio of the centrifugal glass wool fibers, the environment-friendly resin binder and a plaster coating material is (85-93): (7-15): (2-3). A preparation method of the glass wool ceiling board comprises the steps of uniformly spraying the environment-friendly resin binder to the surfaces of the centrifugal glass wool fibers in an atomization state, carrying out wool collection by a wool collector, compressing and conveying collected wool into a curing oven for curing so as to obtain a glass wool board, then, carrying out glass fiber felt facing on the glass wool board, and carrying out compressed plaster coating material spraying according to different decorative patterns. Compared with the prior art, the glass wool ceiling board and the preparation method thereof have the advantages that glass wool ceiling boards of rich and diverse forms can be prepared according to customer requirements, and the ceiling board has heat preservation, heat insulation, sound absorption and fire prevention effects, does not fall dust, is free from formaldehyde release, is harmless to the health of users and is light in weight, so that the requirements on the load of a building can be lowered, and transporting and mounting are more convenient.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL

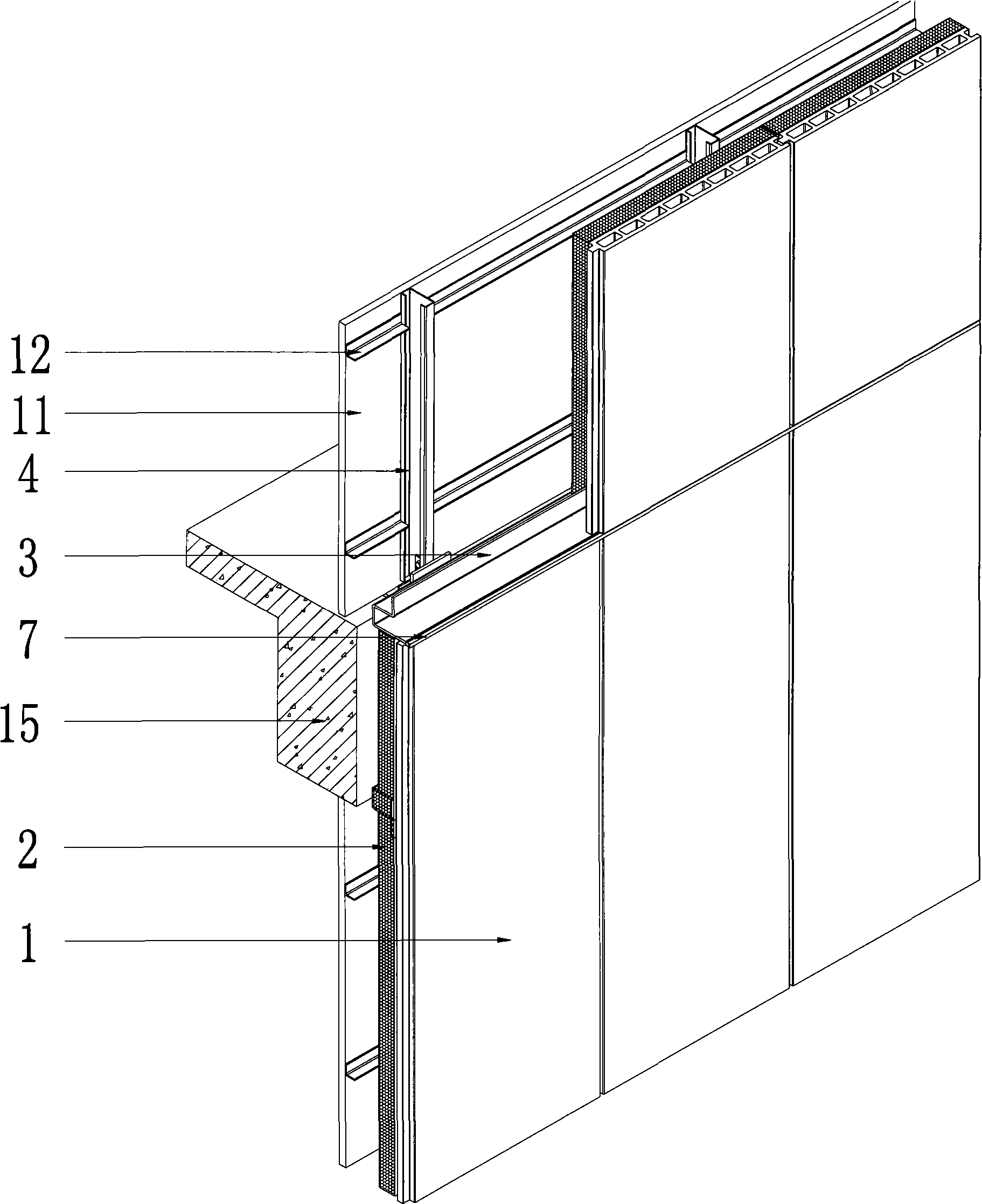

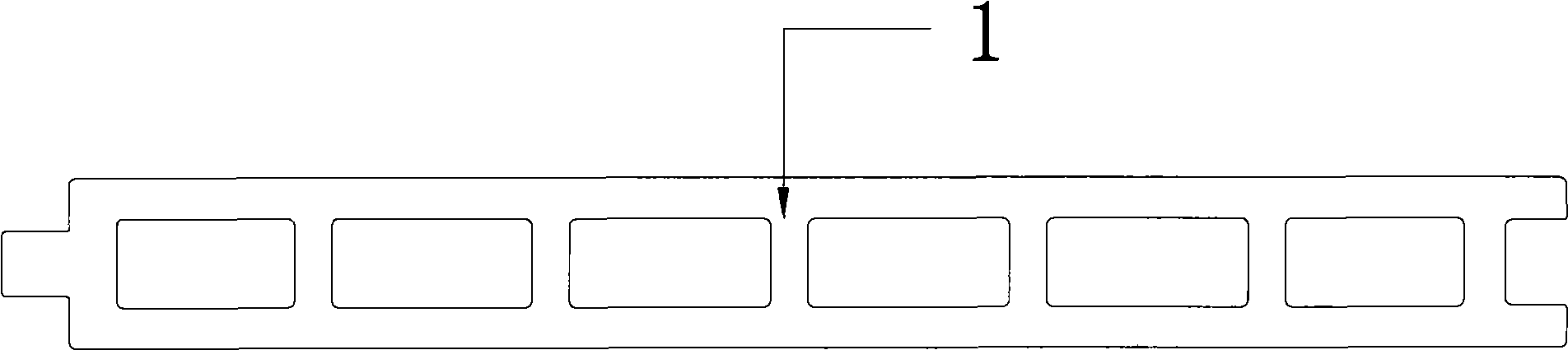

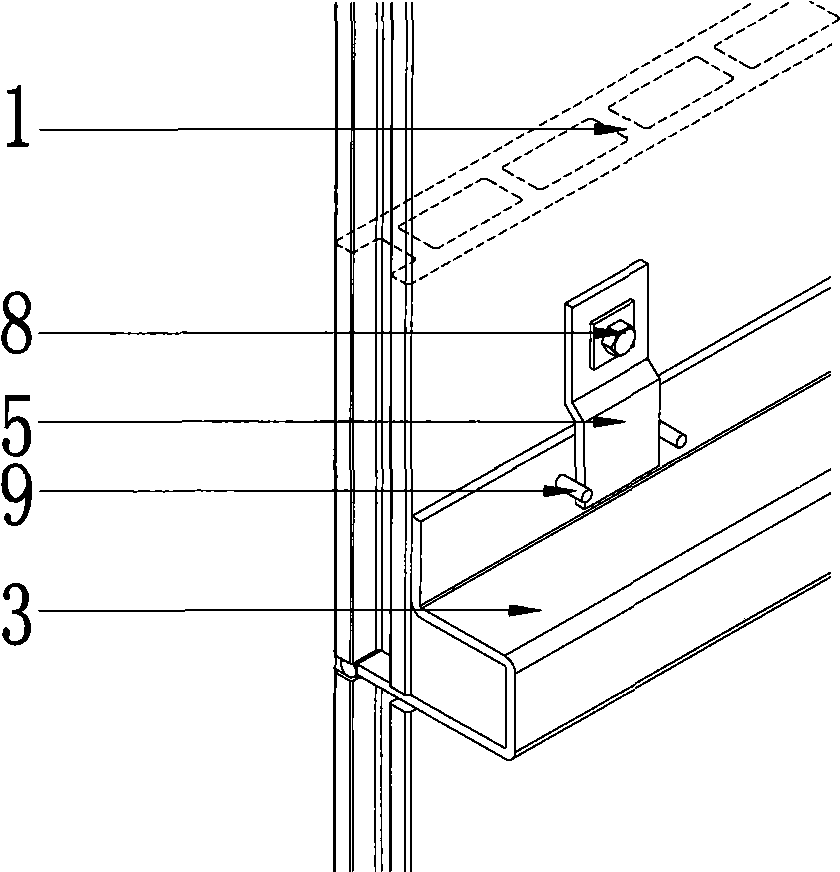

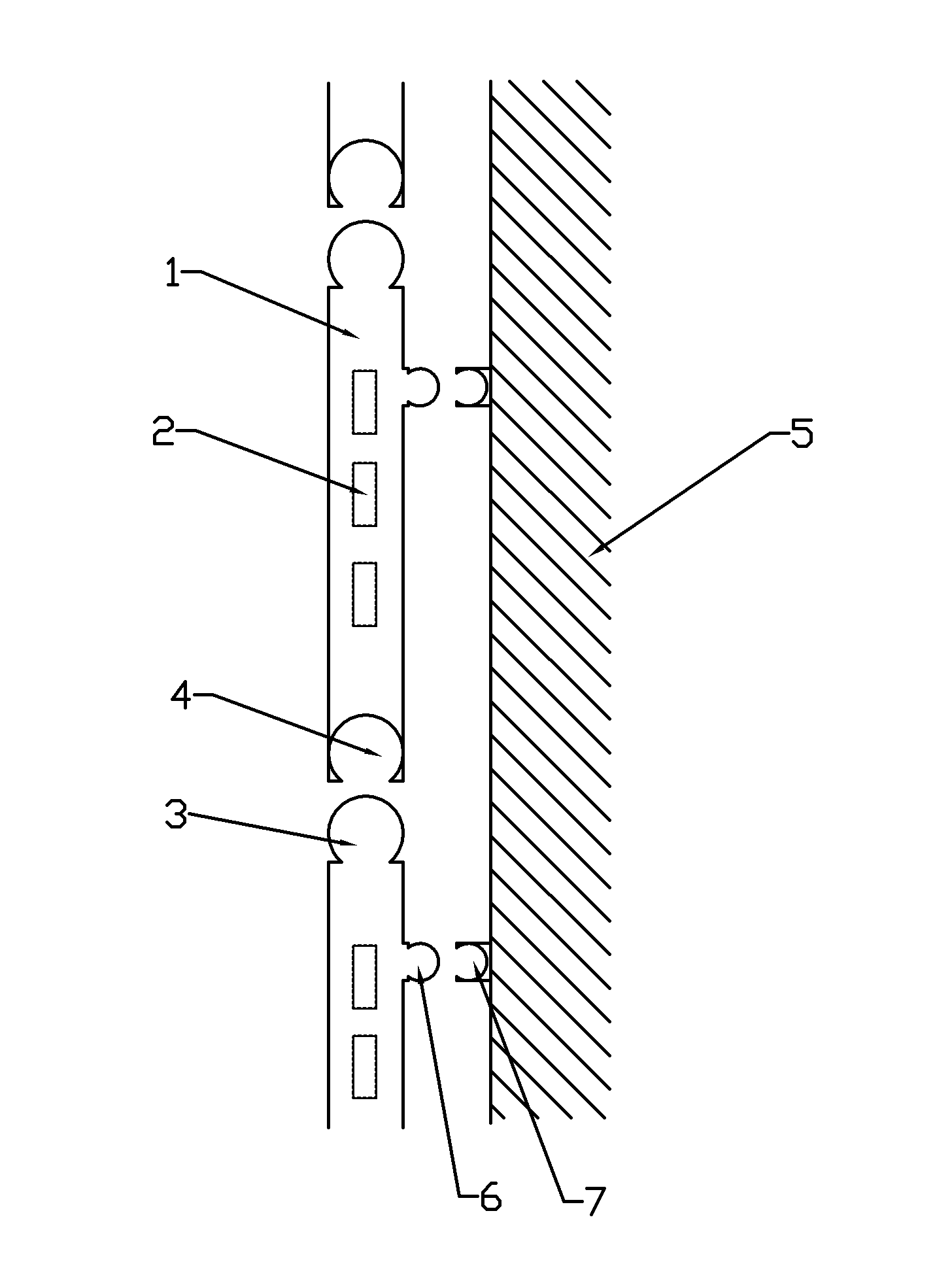

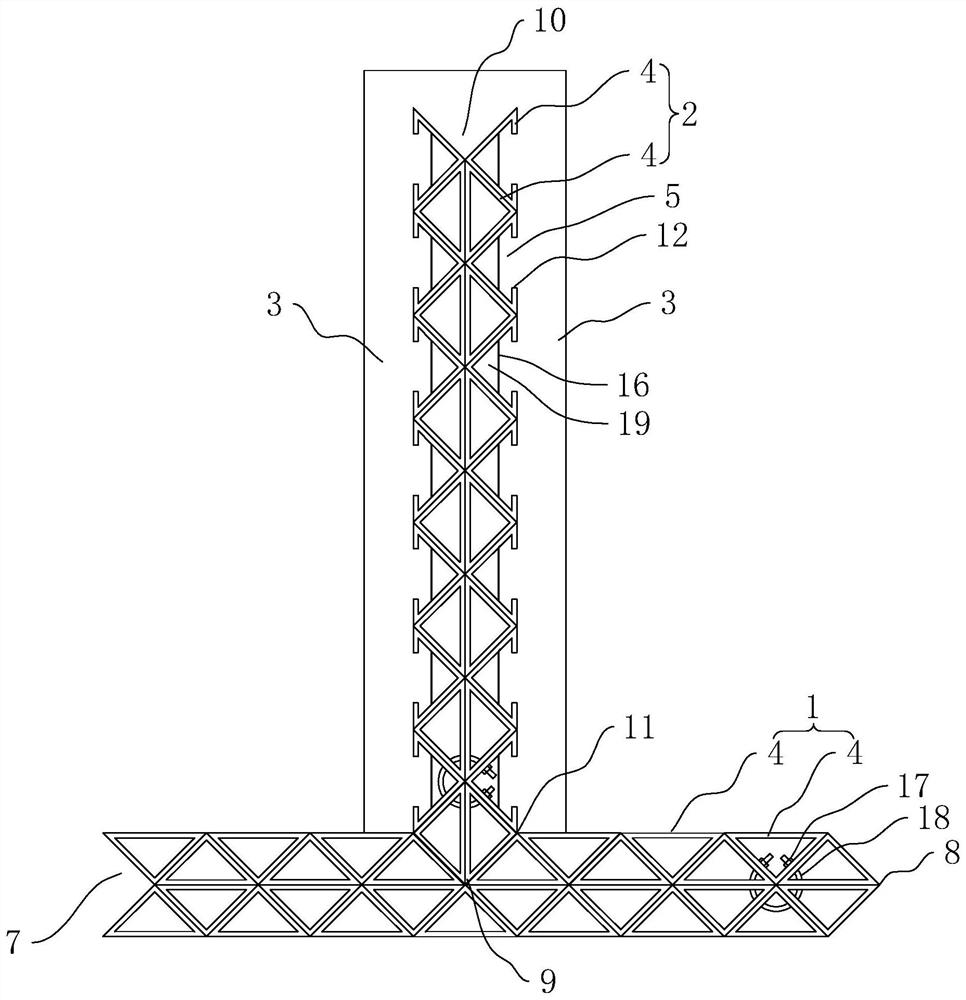

Mounting structure for dry-hanging keel of cement fiberboard external wall system

InactiveCN101545311AImprove installation efficiency and installation accuracyGood thermal insulationCovering/liningsThermal insulationMoisture

The invention discloses a mounting structure for dry-hanging a keel of a cement fiberboard wall system, which comprises a plurality of cement fiberboards, an insulation board, a pendant, an upright post, cross beams and a three-dimensional adjustable supporting seat, wherein the insulation board is affixed to the inner side of the cement fiberboard, the cement fiberboards are fixed on the cross beam through the pendant, the cross beam which is not arranged at a door-window hole part is fixed on the upright post through the three-dimensional adjustable supporting seat, and the cross beam at the door-window hole part is fixed to the upright post directly. The mounting structure mounts the cement fiberboards by adopting a dry-hanging structure, changes the prior wet paste mounting structure, and greatly improves the mounting precision and the mounting efficiency; and besides, the cement fiberboards mounted by the structure have good thermal insulation, waterproof and moisture-proof performances without needing affixing an insulating layer independently.

Owner:沈英

High-grade interior wall paint and preparation method thereof

InactiveCN104804567AGood compatibilityReduce surface tensionAntifouling/underwater paintsPaints with biocidesWater basedThermal insulation

The invention discloses high-grade interior wall paint and a preparation method thereof, and relates to the technical field of architectural coating. The high-grade interior wall paint is prepared from the following ingredients in parts by weight: 85-95 parts of organic silicon modified styrene-acrylic emulsion, 16-25 parts of kieselguhr, 3-7 parts of nano-zinc oxide, 2-7 parts of anatase titanium dioxide, 4-8 parts of kaolin, 5-10 parts of ground calcium carbonate, 2-5 parts of coalescing agent, 0.5-1.8 parts of water-based flatting agent, 0.2-0.6 part of dispersing agent, 0.4-0.9 part of wetting agent, 0.5-1.5 parts of water-based defoamer, 2.0-3.5 parts of thickening agent, 2.5-5.5 parts of pH modifier, 3-7 parts of sterilizing agent and 20-50 parts of water. The high-grade interior wall paint has the beneficial effects that the high-grade interior wall paint prepared by a special formula and the preparation method is free of irritating odors, non-toxic and harmless, good in thermal insulation effect, strong in adhesive force, high in wash resistance and weather resistance, and good in damp-proof effect; other properties of the high-grade interior wall paint conform to the relevant specifications of China.

Owner:CHONGQING PINSHENG PAINT

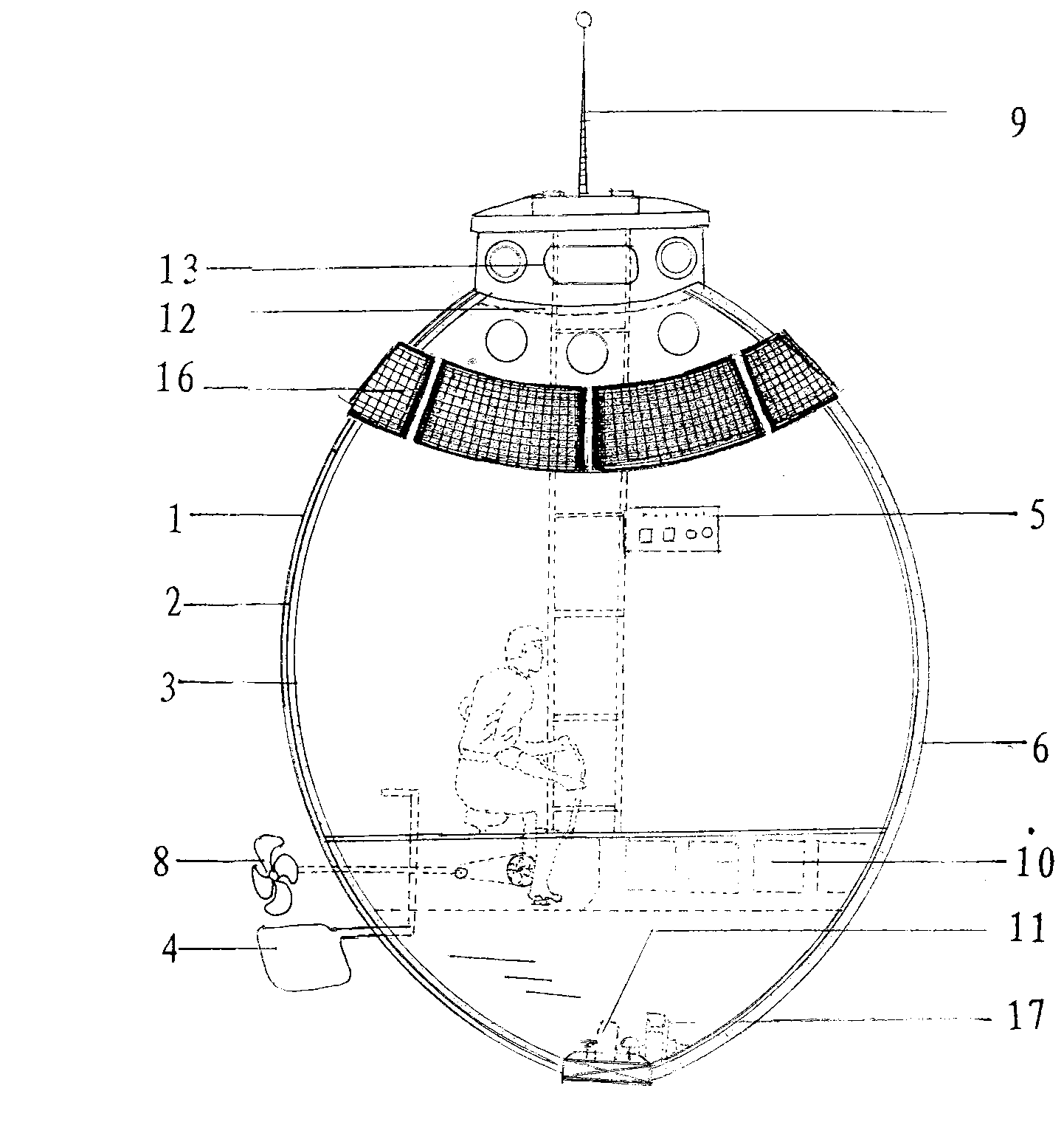

Elliptic sealed lifeboat

The invention discloses an elliptic sealed lifeboat. The elliptic sealed lifeboat has all the advantages of a spherical escape capsule, and has the characteristic of being balanced and upright due to an elliptic shape. The elliptic sealed lifeboat is provided with a water preventer which is in the shape of an axe edge and used for splitting a water surface to reduce an impact force in case of being thrown in air by a tsunami or a surge and then falling into seawater, thus guaranteeing the safety of the lifeboat under the heaps of times of overturning and throwing of violent storm and roaring waves. The lifeboat has the following four characteristics that: 1, the lifeboat has leak tightness and water tightness; 2, the lifeboat can resist a high impact load; 3, the lifeboat can be got up from a ship in distress or from the sea; and 4, the lifeboat has good thermal insulativity so as to avoid the too low temperature of people in a low-temperature environment. According to the lifeboat, a propulsion system is installed on a keel, and can achieve a navigational speed of 1.9 kts via the drive of labour power; and an automatic water-charging ballasting chamber is arranged on the lower part of a main structure to guarantee the balanced, upright and comfortable state of the lifeboat in severe sea conditions. The lifeboat is light in boat body and simple in structure; a safety problem in storm is effectively solved via the sealed type; and by adopting a polyvinyl chloride heat-insulating material, the lifeboat is coldproof in winter and sunproof in summer, thus effectively increasing the safety factor of driving.

Owner:苏州市高展新机电科技有限公司

Ceramics-imitated plate used for construction

InactiveCN102173650ADurable colorGood thermal insulationSolid waste managementThermal insulationCeramic

The invention discloses a ceramics-imitated plate used for construction, which is made from raw materials according to the following percentage by weight: 10% to 80% of PVC (Polyvinyl Chloride), 5% to 10% of processing aid, and the balance of red mud. The ceramics-imitated plate not only can be used as an outer wall cladding, but also can be used as partition plate in buildings and indoor and outdoor floors. The produced ceramics-imitated plate in the invention has the advantages of low manufacturing cost, light weight, unbreakable performance, colour durability, favorable heat preservation and thermal insulation performances and the like and. In the ceramics-imitated plate, the red mud is adopted as a main raw material, so that the pollution of the red mud to the environment can be alleviated. In the invention, a connection method of inserting two panels used by the floor is applied to the outer wall cladding, and the ceramics-imitated plates are fixed to the wall or the floor by using an inserting method, and thus, the fixation is firmer and the construction is more convenient.

Owner:孟扬

Fly ash ceramsite preparation process

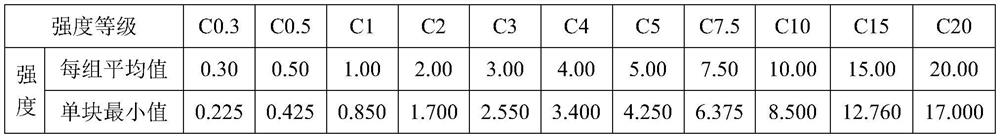

The invention relates to a fly ash ceramsite preparation process, which comprises: doping 10-20% of water into 50-80% of fly ash and 20-40% of a binder, mixing into balls, drying for 12-24 h at a room temperature, placing into a constant temperature oven with a temperature of 70 DEG C to dry for 2-4 h, and carrying out high temperature calcination for 1 h at a temperature of 1200-1300 DEG C to obtain the ceramsite. According to the present invention, the fly ash ceramsite produced through the fly ash ceramsite preparation process has characteristics of low density, light weight and heat insulation; the internal of the fly ash ceramsite has the porous structure so as to provide the good thermal insulation; fire resistance is good, wherein the ceramsite has excellent fire resistance, and the fire resistance of the fly ash ceramsite is more than four times compared with the fire resistance of the ordinary concrete; shock resistance is good, wherein the ceramsite concrete has characteristics of light weight, low elastic modulus and good deformation resistance so as to provide the good shock resistance; water absorption is low, and frost resistance and durability are good; and acid corrosion resistance, alkali corrosion resistance and frost resistance of the ceramsite concrete are superior to acid corrosion resistance, alkali corrosion resistance and frost resistance of the ordinary concrete.

Owner:DALIAN HENGXIANG FLY ASH INTEGRATION UTILIZATION

Multifunctional efficient heat insulation and heat preservation paint formula

InactiveCN108485325AGood thermal insulationExcellent high temperature resistance and fire performanceFireproof paintsThermal insulationTemperature resistance

The invention provides a multifunctional efficient heat insulation and heat preservation paint formula, and relates to the technical field of external wall paint of a building. The multifunctional efficient heat insulation and heat preservation paint formula comprises the following raw materials in parts by weight: deionized water, anti-foaming agents, cellulose, multifunctional auxiliary agents,dispersing agents, wetting agents, preservatives, propanediol, kieselguhr, titanium dioxide, mica powder, silica sol, aerogel and thickening agents. The raw materials are taken according to the weightparts and are processed according to the multifunctional efficient heat insulation and heat preservation paint. After the technical scheme is used, the multifunctional efficient heat insulation and heat preservation paint formula has the beneficial effects that the functional heat insulation and heat preservation paint achieves the functions of heat insulation, heat preservation, air purification, fireproof function and high-temperature resistance.

Owner:童彬原

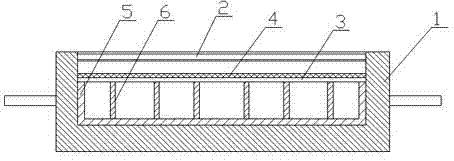

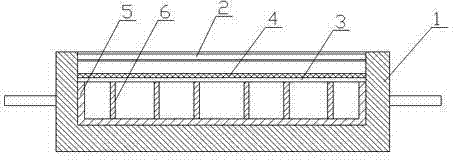

Flat-plate solar heat collector

InactiveCN102494412AReduce lossesGood thermal insulationSolar heating energySolar heat devicesSolar thermal collectorEngineering

The invention discloses a flat-plate solar heat collector and aims to provide a flat-plate solar heat collector which has high heat efficiency and high heat preserving performance. The flat-plate solar heat collector comprises an outer frame, a transparent material plate and a heat insulating layer, wherein the transparent material plate is a transparent plate with a vacuum interlayer; a heat absorbing plate is arranged below the transparent material plate; the heat insulating layer is formed on the inner surface of the outer frame below the heat absorbing plate; and both sides of the outer frame are connected with a water inlet pipe and a water outlet pipe respectively. The transparent material plate has a structure provided with a vacuum layer, so that loss caused on air flow is reduced to zero; and the transparent material plate and the heat absorbing plate on a lower layer are equivalent to vacuum glass with a low-radiation film, so that good heat preserving and heat insulating effects are achieved on a system.

Owner:蔡庭嘉

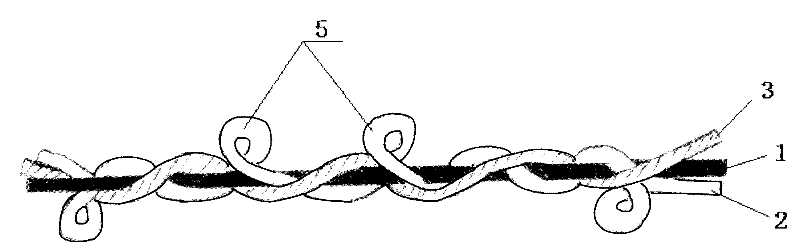

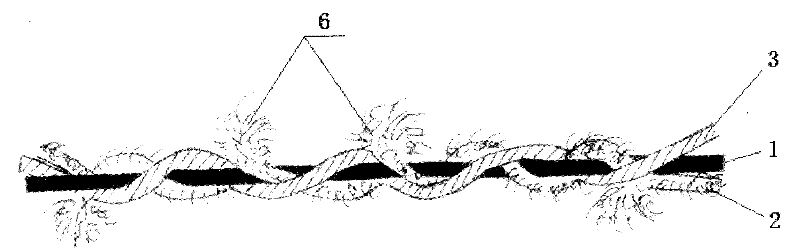

Elastic napping yarn and production method thereof

The invention discloses elastic napping yarn which comprises an inside thread, a napping thread and a coiling thread, wherein the napping thread is sequentially coiled on the inside thread in a preset twisting direction and is napped, wherein the napping thread forms a lint cluster on the inside thread at preset intervals. A production method of the elastic napping yarn comprises the following steps of: napping the snapping thread and the coiling thread, particularly cutting off the single ring of the napping thread and leading the napping thread to form the lint cluster of the napping thread, and realizing the napping of yarn. Compared with the traditional napping cloth, the cloth made of the elastic napping yarn has unique elasticity and warming retention; the problems that the traditional napping cloth has no elasticity and poor warming retention are solved; and meanwhile, a cloth cover has styles of the specific lint cluster and soft hand feeling.

Owner:NINGBO E & F TEXTLE

High-strength, lightweight, environment-friendly and porous interior wall diatomite brick with visible light photocatalysis performance and preparation method of interior wall diatomite brick

ActiveCN106045556AStrong adsorptionGood thermal insulationCeramicwareClaywaresPhotocatalysisAdhesive

The invention relates to a high-strength, lightweight, environment-friendly and porous interior wall diatomite brick with visible light photocatalysis performance and a preparation method of the interior wall diatomite brick. Diatomite, kaoline, chrysotile fibers, a macromolecule adhesive and feldspar are mixed and pressed to form a green body, the green body is dried, calcined and cooled, a diatomite brick is obtained, coated with bismuth tungstate, then calcined and cooled, and the interior wall diatomite brick is obtained. According to the interior wall diatomite brick, the excellent special performance of the diatomite serving as a main base material is utilized, the chrysotile fibers and a bismuth tungstate photocatalyst are added, the mechanical property of the interior wall diatomite brick is improved, and the photocatalysis effect under visible light is realized. Besides, a novel environment-friendly building material capable of decomposing toxic and harmful gas in a room and integrating functions of humidity conditioning, thermal insulation, antibacterium, sound absorption, heat preservation, air purification, flame retardance and the like can be further produced.

Owner:CENT SOUTH UNIV

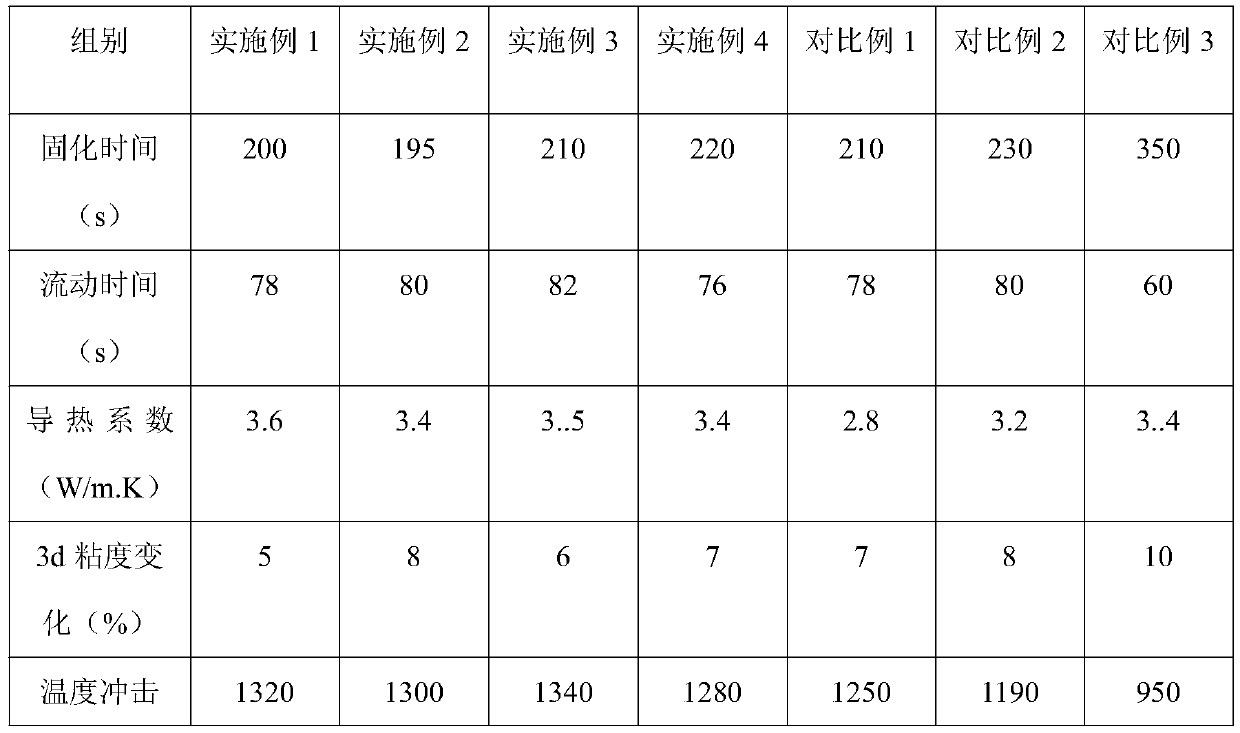

Single-component epoxy resin flowing type underfill adhesive and preparation method thereof

ActiveCN111560232AIncrease thermal conductivity coefficientIncrease contact areaNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

The invention belongs to the field of filling adhesives, and especially relates to a single-component epoxy resin flowing type underfill adhesive. The underfill adhesive comprises the following components in parts by mass: 10-50 parts of bisphenol F epoxy resin, 10-20 parts of a first filler, 5-10 parts of a second filler, 5-10 parts of a curing agent, 2-5 parts of a curing accelerator, 5-15 partsof a reactive diluent, 0.1-3 parts of a flexibilizer and 0.1-3 parts of an ion trapping agent, wherein the particle size of the first filler is greater than the particle size of the second filler. The fillers used in the invention are relatively low in mass fraction; through organic cooperation of the first filler and the second filler, the thermal conductivity coefficient of the whole underfilladhesive can be increased while the viscosity of a system is controlled; and the underfill adhesive has the characteristics of good cohesiveness, good thermal conductivity and insulation performance,good heat resistance, low viscosity, good fluidity, low hygroscopicity and the like.

Owner:东莞市新懿电子材料技术有限公司

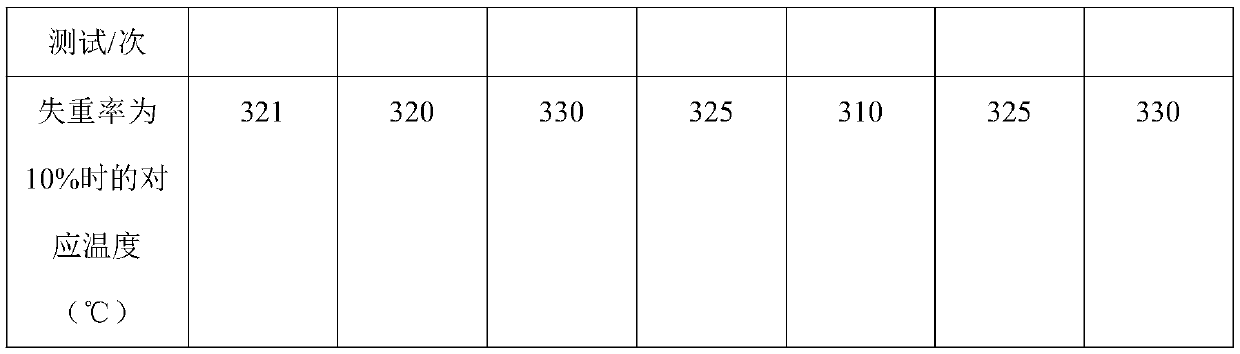

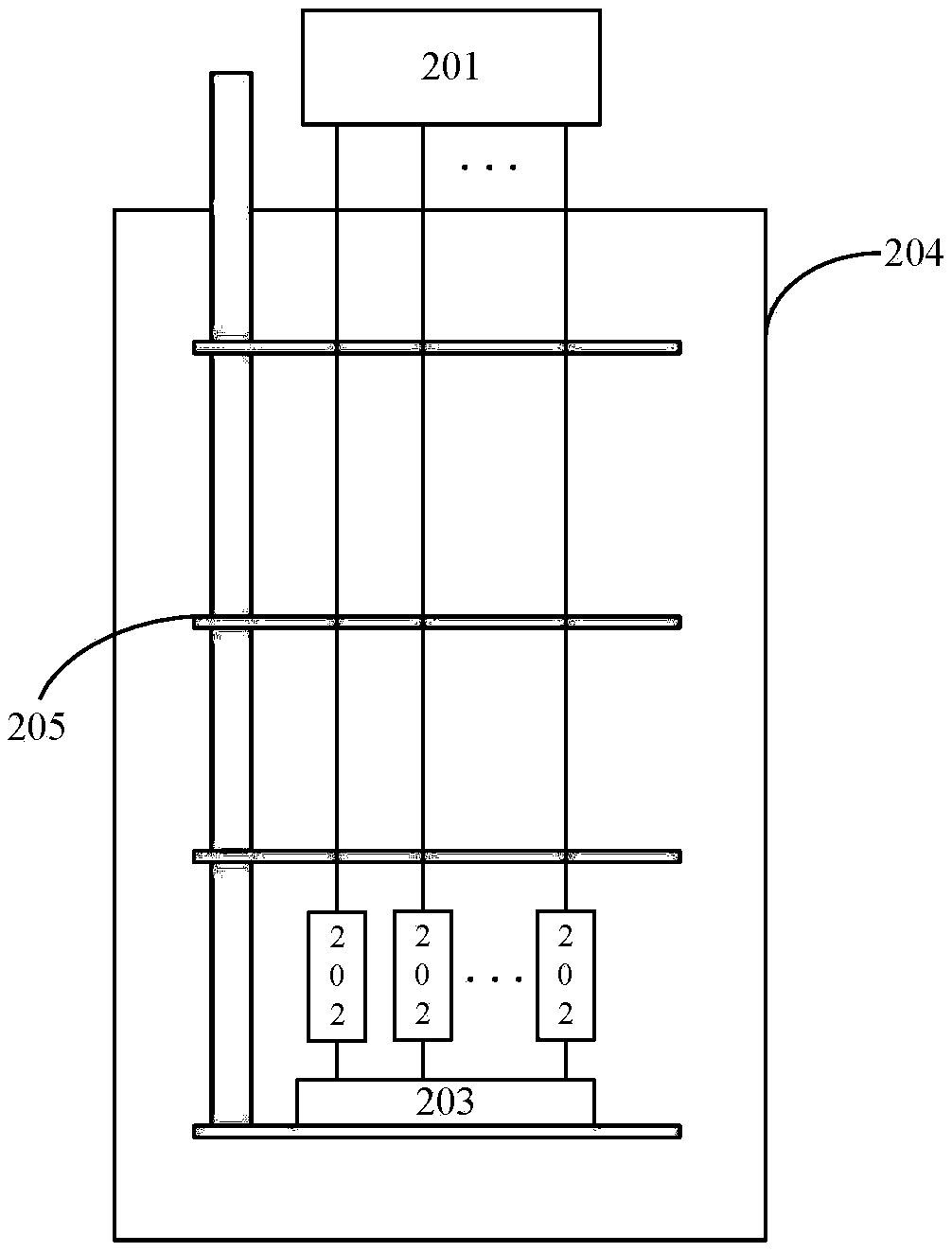

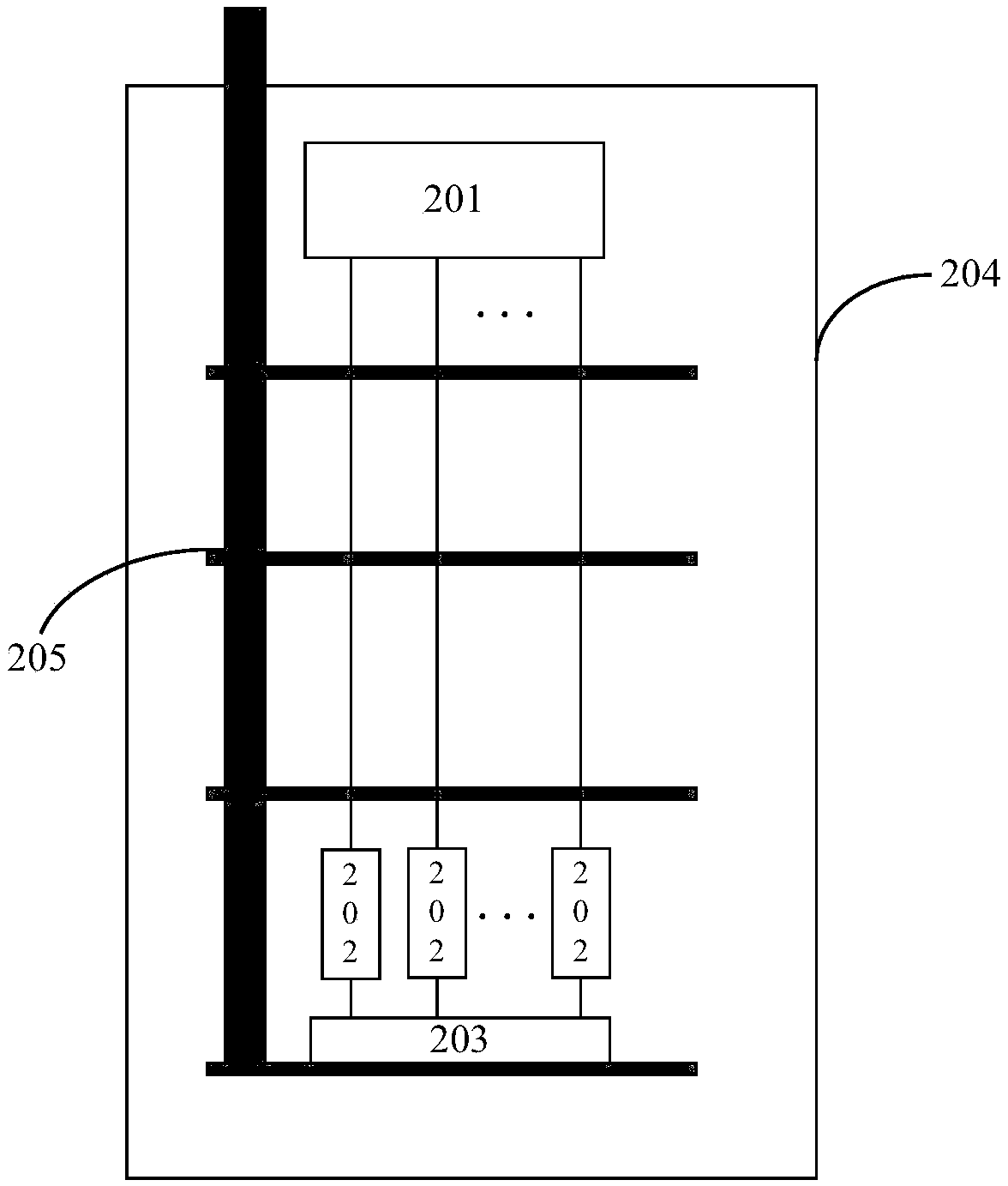

Quantum bit control device

ActiveCN111191790AReduced control signal deliveryGood thermal insulationQuantum computersPhotovoltaic detectorsSystem capacity

The invention discloses a quantum bit control device, which comprises a control signal generator, N photoelectric detectors, a quantum chip and a shielding device, wherein N is a positive integer greater than 1; the control signal generator is located in a first temperature zone and used for generating N paths of optical control signals and sending the N paths of optical control signals to the N photoelectric detectors located in the shielding device, and the interior of the shielding device is in a vacuum state; and the N photoelectric detectors are positioned in a second temperature zone ofwhich the temperature is lower than that of the first temperature zone, and are used for converting the received optical control signal into an electric control signal and sending the electric controlsignal to the quantum chip positioned in the shielding device for quantum bit control. According to the invention, optical control signals are adopted for transmission, due to the fact that the heatconductivity coefficient of the optical fiber is small, heat transfer from the first temperature zone to the second temperature zone is greatly reduced, and under the same refrigeration power, more control signals can be supported, and system capacity expansion is supported.

Owner:HUAWEI TECH CO LTD

Die casting head heat-preservation device for gravity casting and pouring

The present invention belongs to the field of casting apparatus, and is especially one heat insulating and feeding unit for gravitationally casting hard casting head. The present invention features that the hard casting head of cast iron is provided with several downward extending blind holes filled with heat insulating material in the wall, heat insulating material painted to the inner wall and heat insulating material covering the outer wall. The casting head has the features of high heat insulating effect, high feeding effect, and low cost.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

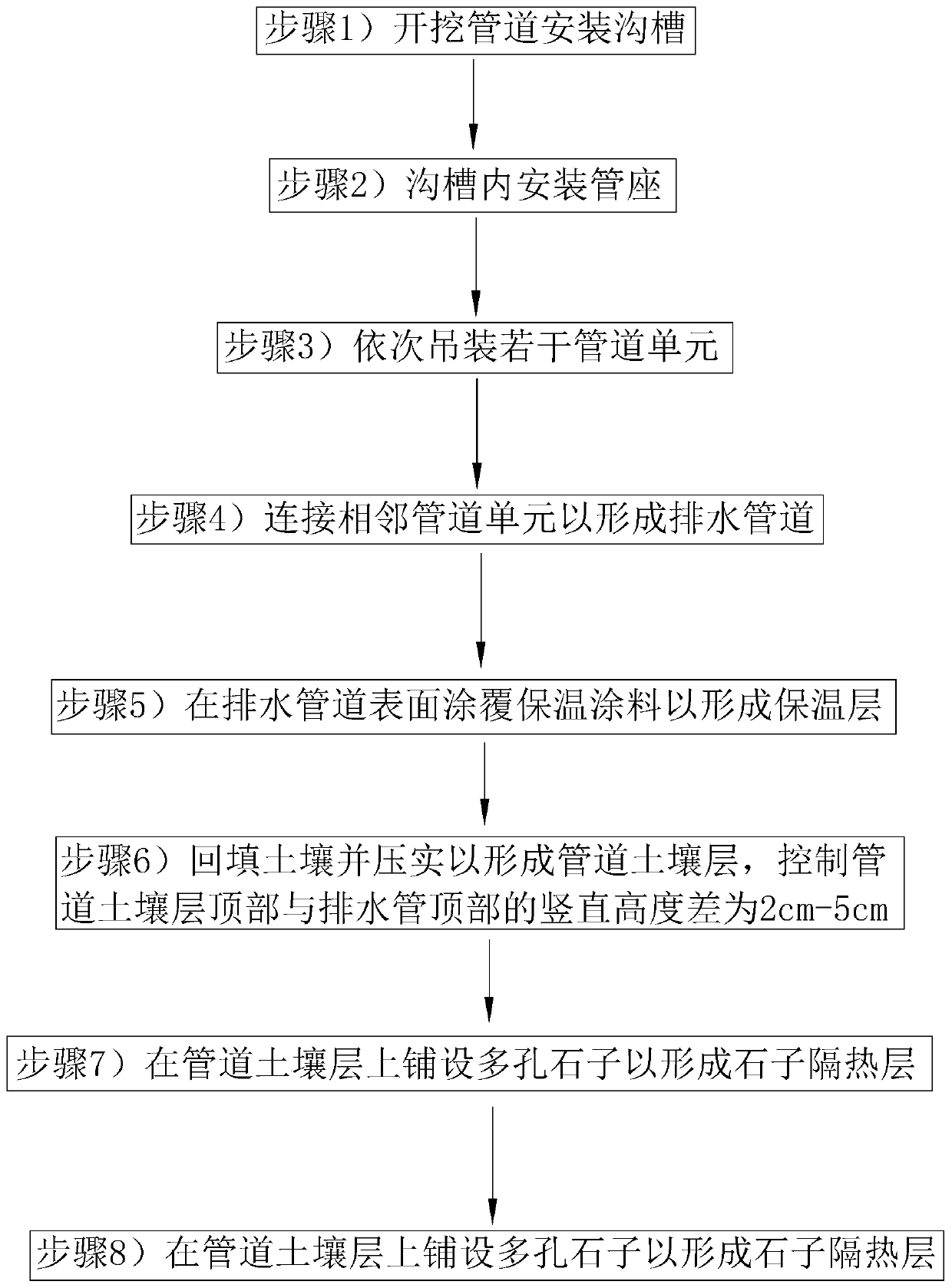

Water drainage pipeline mounting process

InactiveCN111197343AGood thermal insulationBlock heat flowSewer pipelinesThermal insulationSoil science

The invention relates to the field of pipeline mounting, in particular to a water drainage pipeline mounting process. The water drainage pipeline mounting process comprises the following steps: step 1) of excavating a pipeline mounting groove; step 2) of mounting a tube seat in the groove; step 3) of sequentially hoisting a plurality of pipeline units; step 4) of connecting adjacent pipeline unitsto form a water drainage pipeline; step 5) of coating thermal-insulation paint on the surface of the water drainage pipeline to form a thermal insulation layer; step 6) of backfilling soil and compacting the soil to form a pipeline soil layer, and controlling vertical height difference between the top of the pipeline soil layer and the top of the water drainage part to be 2cm-5cm; step 7) of spreading porous stones on the pipeline soil layer to form a stone heat insulation layer; and step 8) of backfilling soil into the stone heat insulation layer, and compacting the stone heat insulation layer to repair ground. The water drainage pipeline mounting process has the effects of enabling a water body in a water drainage tube to be not liable to ice and expand, and enabling the water drainagepipeline to be not liable to damage.

Owner:广东荣潮拓展建设有限公司

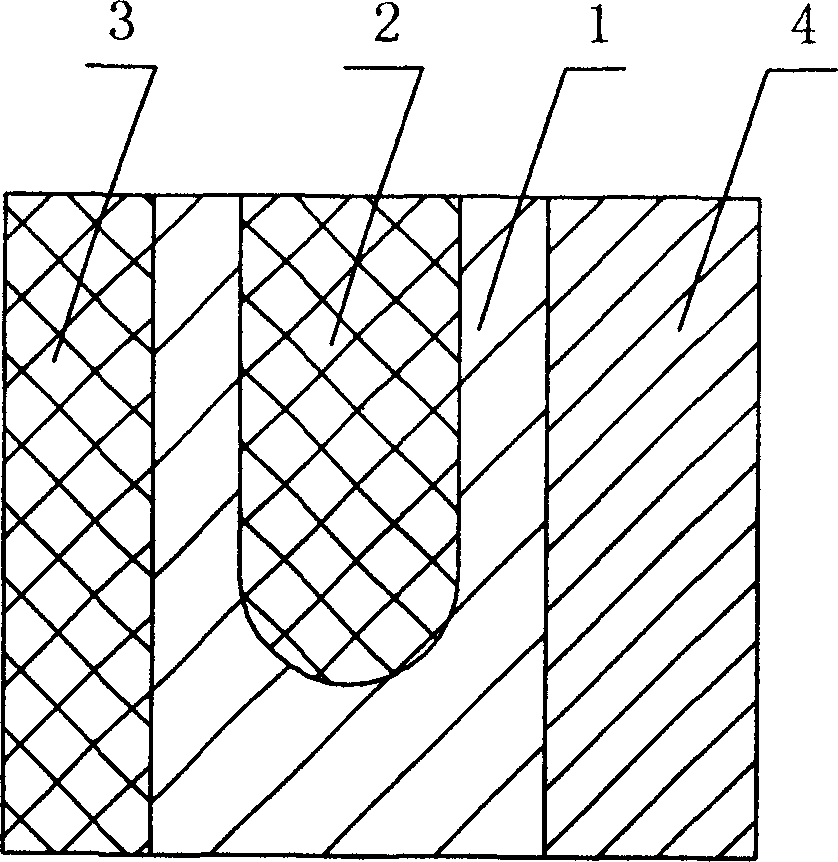

Insulated heat-conducting substrate with high reliability

ActiveCN103325743AGood thermal insulationGood adhesionSemiconductor/solid-state device detailsSolid-state devicesCopper foilBrazing

The invention relates to an insulated heat-conducting substrate with high reliability. The insulated heat-conducting substrate comprises an aluminum or aluminum alloy base body which is deposited with an amorphous aluminum transition layer. The aluminum transition layer is deposited with an AlON insulated heat-conducting ceramic layer through a PECVD method. According to the insulated heat-conducting ceramic layer, a copper foil is welded on the insulated heat-conducting ceramic layer through active brazing process. The insulated heat-conducting substrate with high reliability in the invention has good heat conducting insulation performance, and the heat conducting coefficient is larger than or equal to 100W / mk; the adhesion between layers of the substrate is good, the thermal stress is low, and the reliability is good; and the insulated heat-conducting substrate can be used as a substrate of an electronic component with high integration.

Owner:杭州锐河科技有限公司

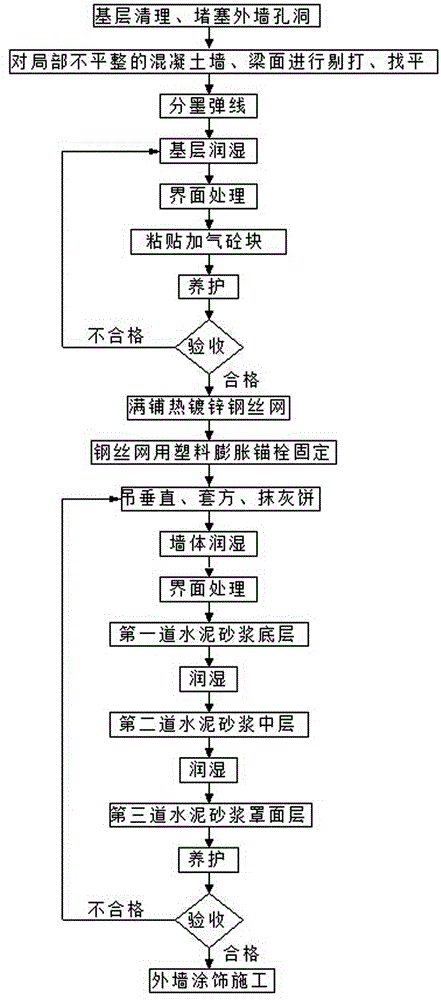

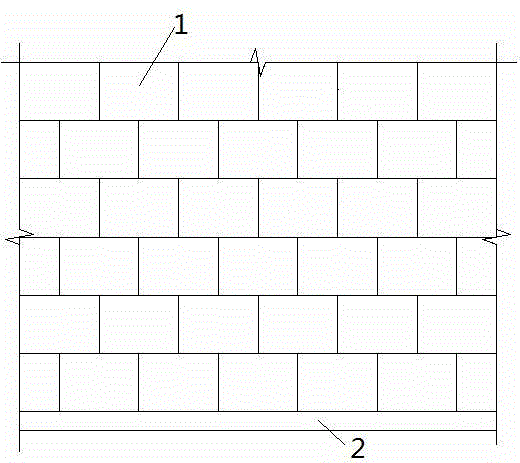

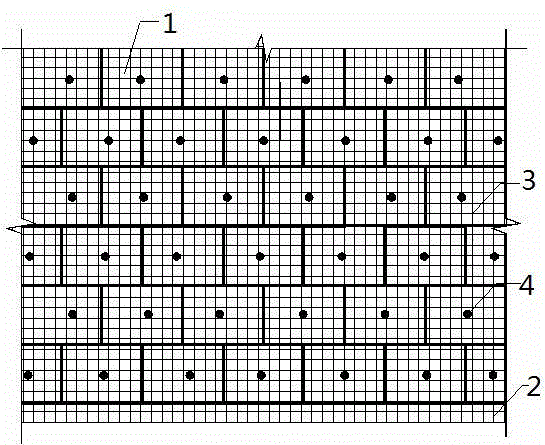

Outer wall autoclaved aerated concrete self heat insulation system same material thermal bridge treatment construction method

ActiveCN104481157AGood thermal insulationMaintain appearance qualityClimate change adaptationPassive housesWeather resistanceAutoclaved aerated concrete

The invention relates to an outer wall autoclaved aerated concrete self heat insulation system same material thermal bridge treatment construction process. The process includes bonding the autoclaved aerated concrete building blocks to the outsides of building outer walls, columns and beams, utilizing the heat insulation layer on the portion of the concrete thermal bridge to meet the requirement of the thermal bridge portion for building energy saving and enable the reasonable service life of external wall heat insulation to be prolonged from 25 years to over 50 years of service life of structure design of the building, the problem that the weather resistance of other heat insulation materials cannot be consistent with the service life of the buildings, and the shortcomings of poor fire resistance and poor safety of the heat insulation material are overcome.

Owner:重庆建工建筑产业技术研究院有限公司 +2

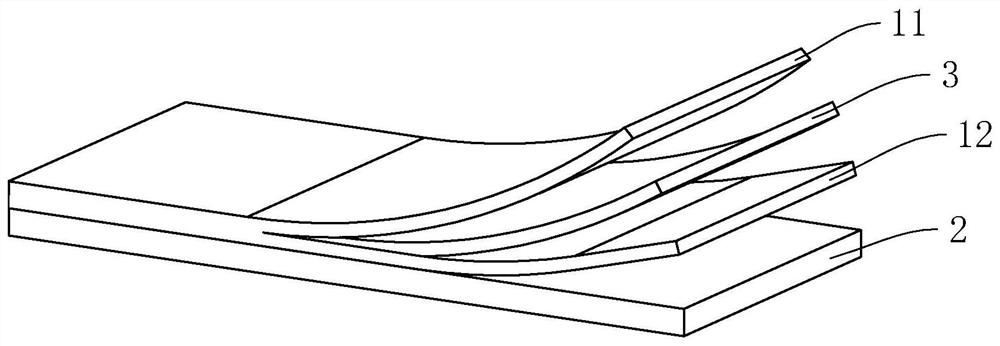

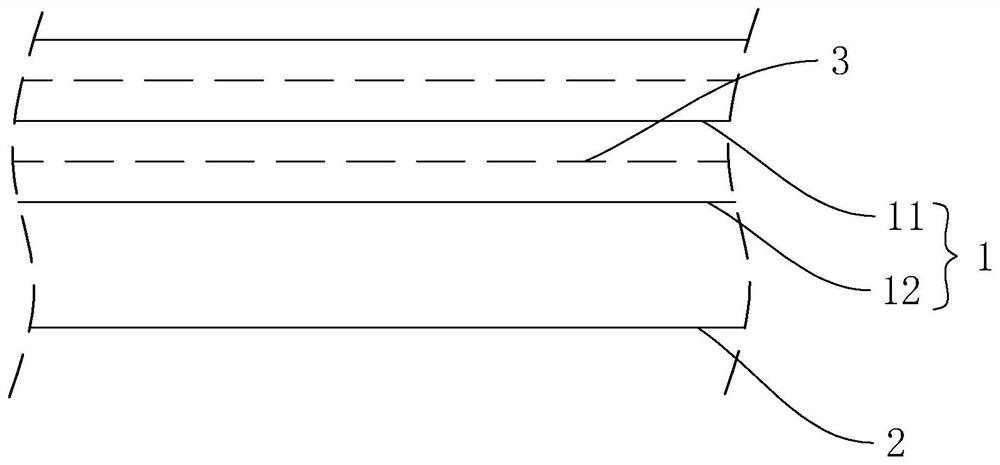

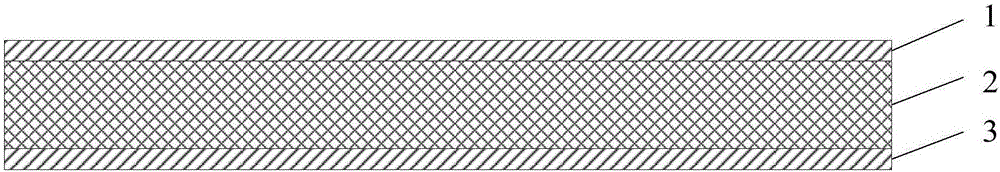

Composite heat-insulation flexible facing sheet for building wall as well as processing technology and application of composite heat-insulation flexible facing sheet

PendingCN113858719AGood thermal insulationLight weightCovering/liningsGlass/slag layered productsEmulsionEther

The invention relates to the technical field of building wall decoration, and particularly discloses a composite heat-insulation flexible facing sheet for a building wall and a processing technology and an application of the composite heat-insulation flexible facing sheet for the building wall. The composite heat-insulation flexible facing sheet comprises a soft porcelain facing layer and a heat-insulation bottom layer, and a toughening layer is arranged in the soft porcelain facing layer; the soft porcelain facing layer is prepared from the following raw materials: water, a dispersing agent, a defoaming agent, cellulose ether, an emulsion, blast furnace mineral powder, tailing slag, wollastonite powder, quartz sand, fibers, a thickening agent and pigment; the heat-insulation bottom layer is prepared from the following raw materials: water, cellulose ether, a wetting agent, a dispersing agent, a defoaming agent, a pH regulator, a cosolvent, a sterilizing agent, an emulsion, a water repellent agent, silicon dioxide aerogel, hollow glass beads and a thickening agent. According to the composite heat-insulation flexible facing sheet, through the synergistic effect of the glass fiber grid cloth, the soft porcelain facing layer and the heat-insulation bottom layer, the composite heat-insulation flexible facing sheet not only has good heat insulation and heat preservation performance, but also has the advantages of being light in self weight, good in flame retardance, good in flexibility, good in durability and easy and convenient to construct.

Owner:北京莱恩斯新材料科技有限公司

Green energy-saving fabricated building wall part

The invention relates to the technical field of building materials, in particular to a green energy-saving type fabricated building wall part. The green energy-saving type fabricated building wall part comprises a horizontal part used as a floor framework, a vertical part used as a partition wall framework and concrete cast-in-place layers arranged on the two sides of the vertical part. The horizontal part and the vertical part are each formed by splicing a plurality of triangular prism pipe bodies, the upper surface and the lower surface of the horizontal part are horizontal, the two side faces of the vertical part are vertical and parallel to each other, a plurality of grooves are formed in the two sides of the vertical part, and steel bars are fixed in the grooves and extend into the concrete cast-in-place layer. The green energy-saving type fabricated building wall part is easy to splice and good in heat preservation, heat insulation and sound insulation effects.

Owner:江阴市先锋建筑有限责任公司

Low-energy consumption oiling agent blending tank

The invention discloses a low-energy consumption oiling agent blending tank. The tank comprises an outer cylinder head, an inner cylinder head, an inner cylinder, an outer cylinder, a top cover and a guide plate. The top cover is arranged at the top of the inner cylinder. The outer cylinder sleeves the inner cylinder. The inner cylinder head is welded and fixed to the lower end of the inner cylinder. The outer cylinder head is welded and fixed to the lower end of the outer cylinder. The outer cylinder, the outer cylinder head, the inner cylinder and the inner cylinder head form a jacket cavity. The upper end of the jacket cavity is sealed to form an enclosed cavity. The guide plate is arranged in the jacket cavity and helically coils the outer wall of the inner cylinder from top to bottom. The outer wall of the jacket cavity is provided with a heat insulation layer. The heat insulation layer has a two-layer composite structure, an inner heat insulation layer of the two-layer composite structure is glass fiber heat insulation cotton and an outer heat insulation layer is a vacuum insulated plate. The helical line formed through the guide plate is a pitch-variable helical line and the pitch is increased from top to bottom and the cross section of the guide plate is a V-shaped structure. The low-energy consumption oiling agent blending tank has the advantages of less heat lost, low energy consumption and high heat exchange efficiency.

Owner:孙萍

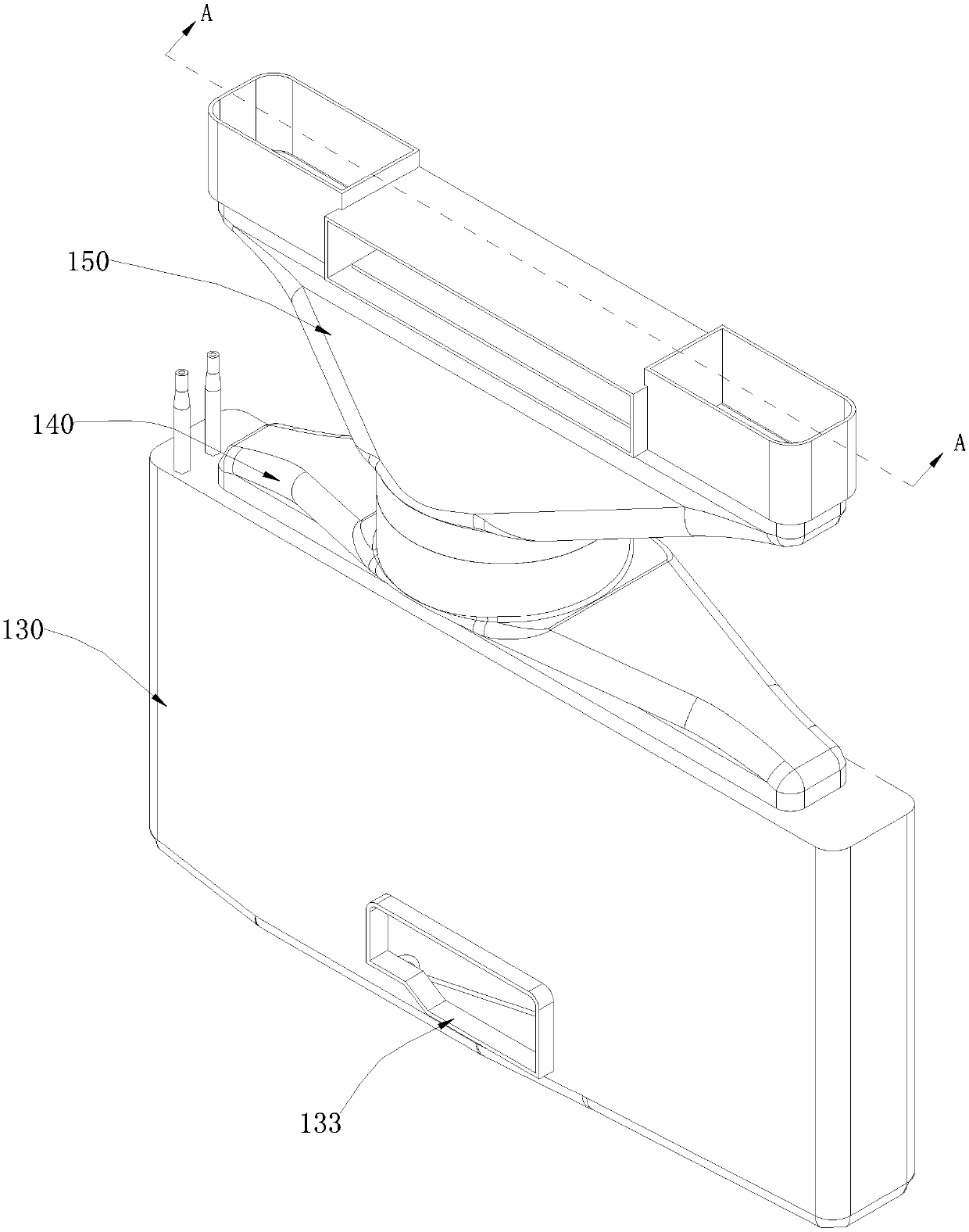

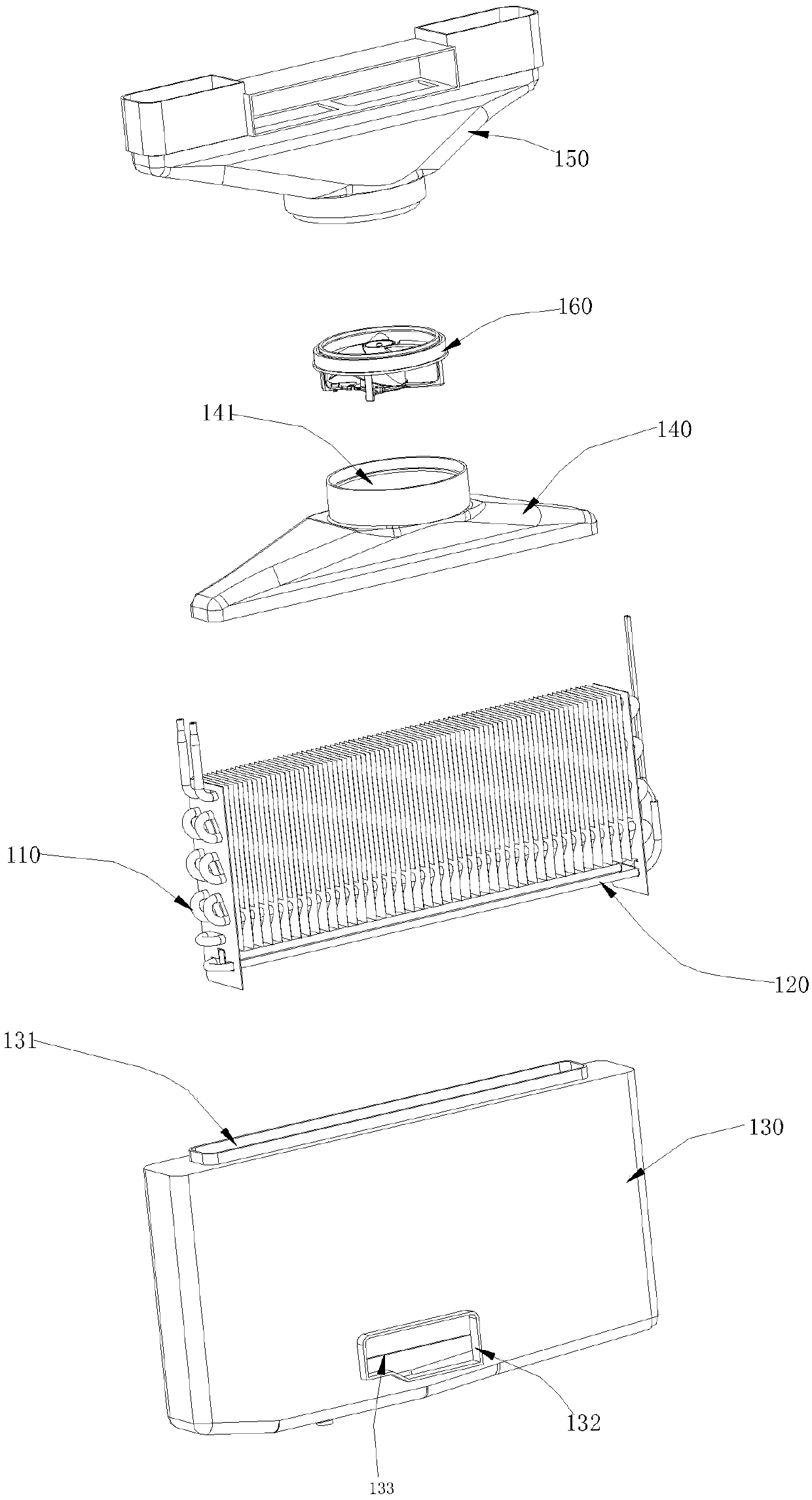

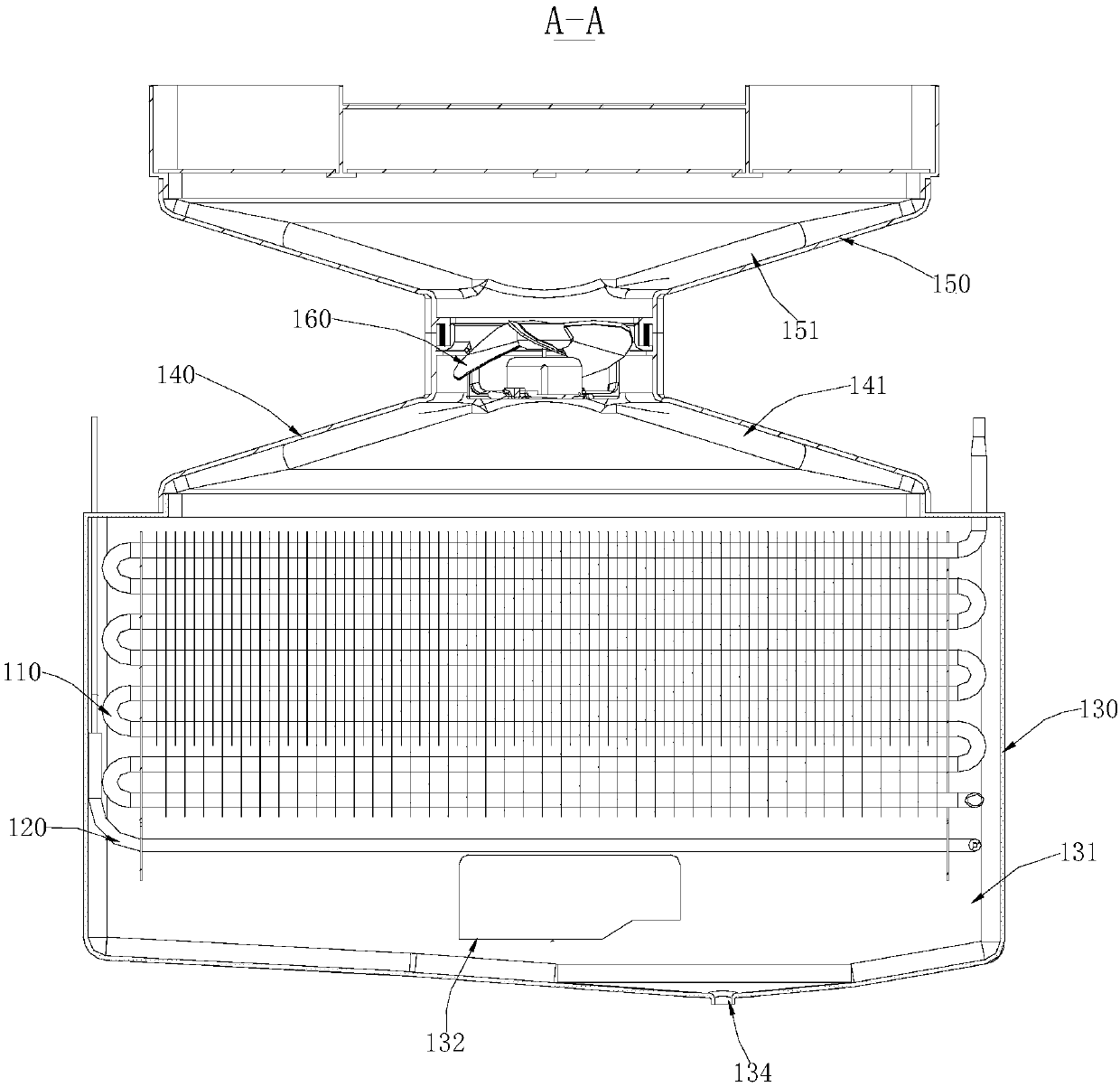

Refrigerator air-cooling evaporator defrosting structure and refrigerator

InactiveCN109539674AImprove defrosting efficiencyGood thermal insulationLighting and heating apparatusDefrostingRefrigerator carEvaporator

The invention discloses a refrigerator air-cooling evaporator defrosting structure and a refrigerator. The refrigerator air-cooling evaporator defrosting structure comprises a fin evaporator and a heater, wherein the heater is positioned below the fin evaporator and is adjacent to the fin evaporator; the refrigerator air-cooling evaporator defrosting structure is characterized by further comprising a sealing thermal insulating box, wherein the sealing thermal insulating box is provided with a hollow cavity; an opening in one end of the hollow cavity is upwards; and the fin evaporator and the heater are accommodated in the hollow cavity. According to the refrigerator air-cooling evaporator defrosting structure, the fin evaporator and the heater are accommodated in the hollow cavity, heat generated by the heater is unlikely to lose and can be better used for defrosting the fin evaporator, so that the defrosting efficiency can be improved.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

Blueberry preservation method

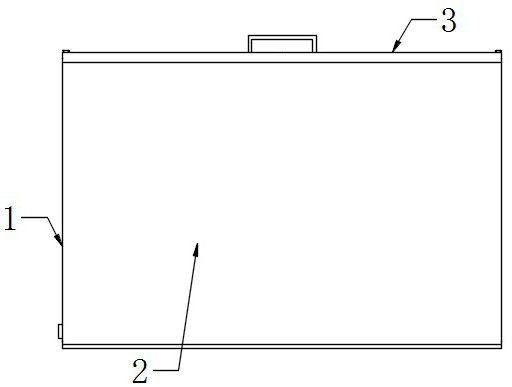

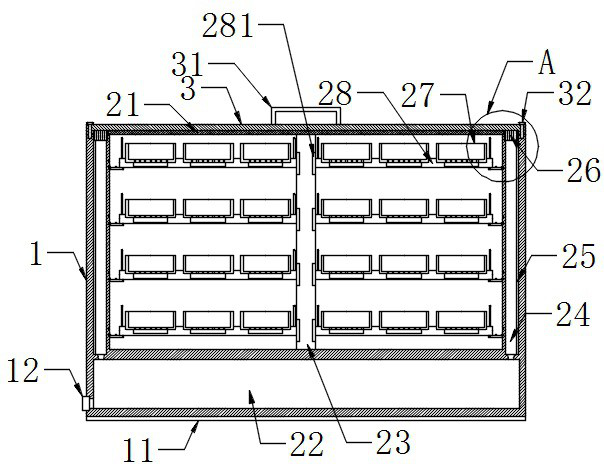

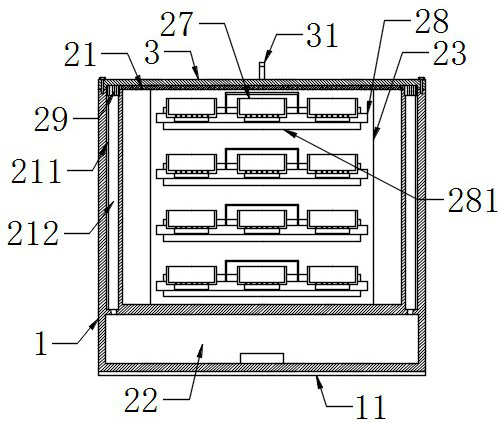

PendingCN114044244AGood thermal insulationMelting fastDomestic cooling apparatusLighting and heating apparatusIce storageHeat conservation

The invention provides a blueberry fresh-keeping method. The method comprises the following steps: (1) treatment before harvesting; and (2) treatment after harvesting. A blueberry fresh-keeping device used in the step (2) comprises a heat preservation box body, a storage fresh-keeping mechanism and a heat preservation box cover, the storage fresh-keeping mechanism is arranged in the heat preservation box body, the heat preservation box cover is installed on the upper end face of the heat preservation box body, a water storage cavity is formed in the lower side of the interior of the heat preservation box body, first ice storage cavities are symmetrically formed in the left side and the right side of the interior of the heat preservation box body, first rubber sealing plug strips are plugged into the upper end faces of the first ice storage cavities, first vacuum heat insulation plates are bonded to the right sides of the inner walls of the first ice storage cavities, and second ice storage cavities are symmetrically formed in the front side and the rear side of the interior of the heat preservation box body. By means of the design, the problem that original blueberries are prone to rot in the transferring process is solved, the structure is reasonable, the heat preservation and refrigeration capacity is achieved, the blueberries can be conveniently stored, and the situation that the blueberries are prone to rot in the transferring process is avoided.

Owner:紫云自治县天赐农林发展有限公司

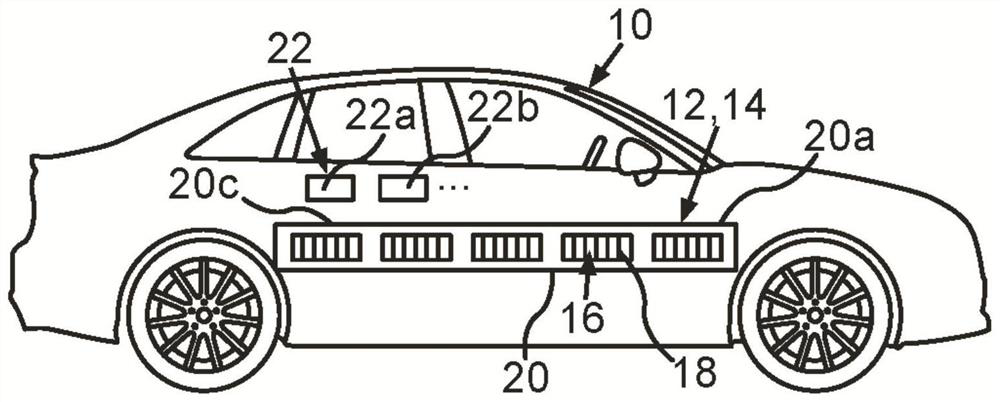

Housing assembly for high-voltage energy accumulator and vehicle

PendingCN111942182AGood thermal insulationReduce cooling powerElectric devicesElectric propulsion mountingIn vehiclePower grid

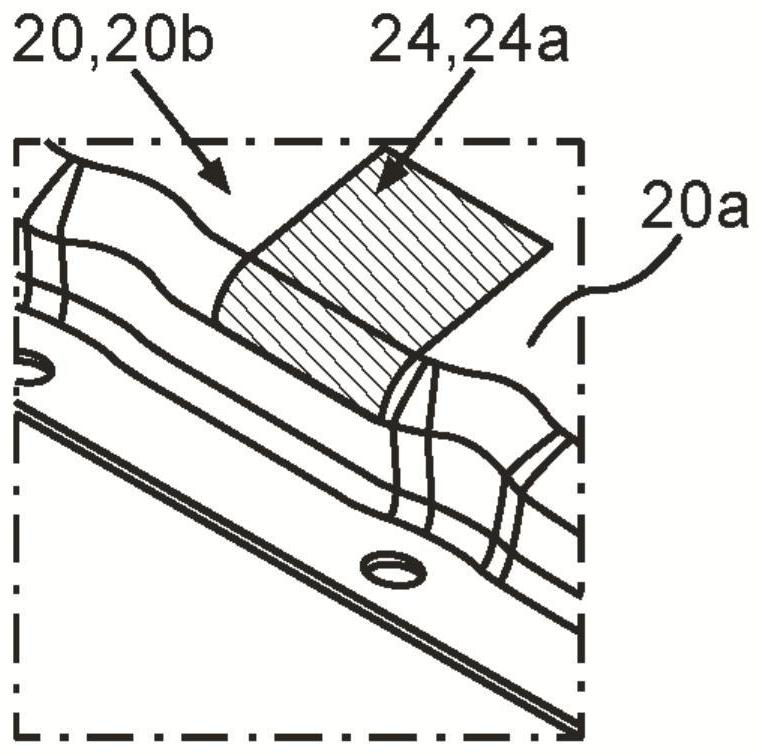

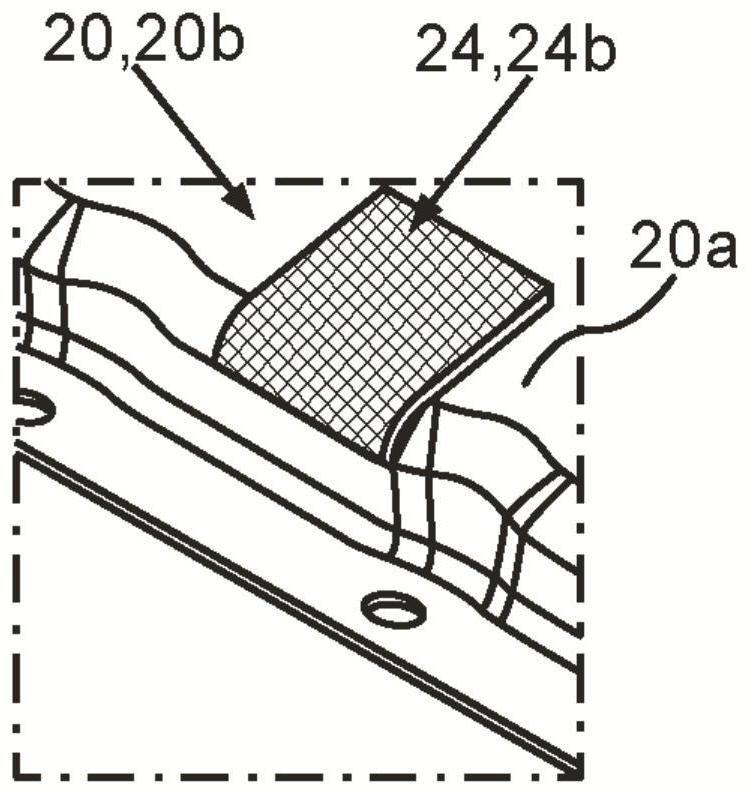

The invention relates to a housing arrangement (14) for a high-pressure accumulator (12) of a motor vehicle (10), comprising a housing (20) for receiving a plurality of energy storage modules (16), the housing has an outer side (20a) facing away from the plurality of energy storage modules (16) in a state in which the plurality of energy storage modules (16) are received in the housing (20). Here,the housing arrangement (14) has an electrically insulating insulating element (24; 24a, 24b, 24c), which is arranged in at least one defined region (20c) of the outer side (20a) of the housing (20),said defined region facing at least one on-board electrical system component (22a, 22b) of the on-board electrical system (22) comprised by the motor vehicle (10) when the housing (20) is in its normal installation position in the motor vehicle (10), the voltage potential ratio being lower than 12.

Owner:AUDI AG

Construction process of cast-in-place foam concrete self-insulation wall

PendingCN113818602AGood thermal insulationLonger and more stable thermal insulationWallsHeat proofingRebarHeat conservation

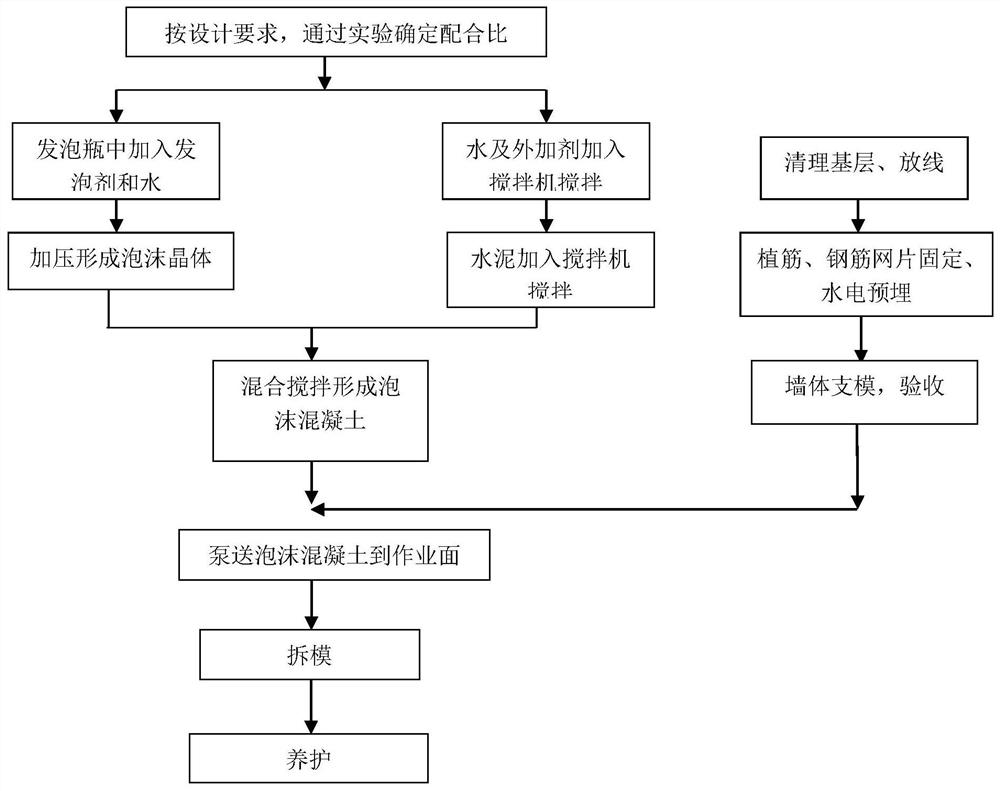

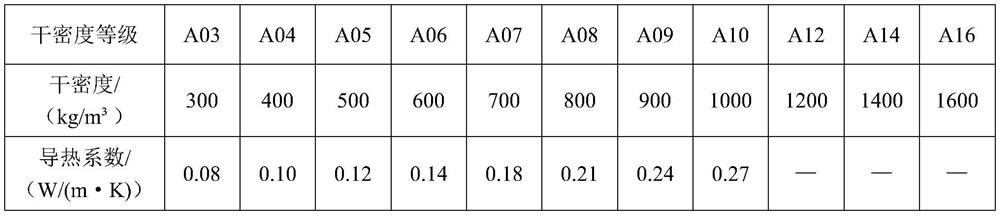

The invention discloses a construction process of a cast-in-place foam concrete self-insulation wall. The process comprises the following steps of: firstly, determining a mix proportion through an experiment according to design requirements; adding a foaming agent and water into the foaming bottle, and pressurizing to form foam crystals; adding the water and the additive into a stirrer for stirring; adding the cement into the stirrer for stirring; adding the foam crystals into a stirrer for stirring, and mixing and stirring to form foam concrete; cleaning a base layer and paying off; embedding steel bars, fixing a steel bar mesh, and pre-burying water and electricity; carrying out wall formwork erecting and acceptance inspection; pumping the foam concrete to a working face; removing the formwork; and performing maintenance. The invention has the advantages of light weight, heat preservation, heat insulation, sound insulation and noise reduction, good fire resistance, good low-elasticity damping performance, no plastering layer, good integrity, convenience in construction, reduction of construction procedures, shortening of construction period, good environmental protection performance, reduction of comprehensive cost and the like.

Owner:浙江重誉防水保温工程有限公司

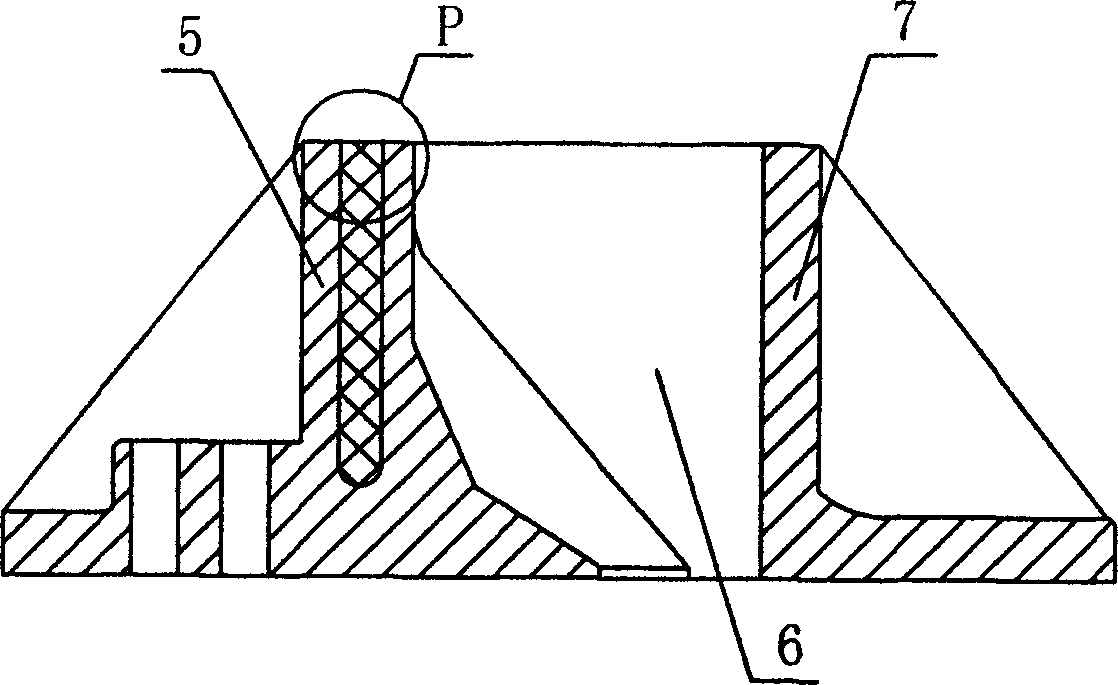

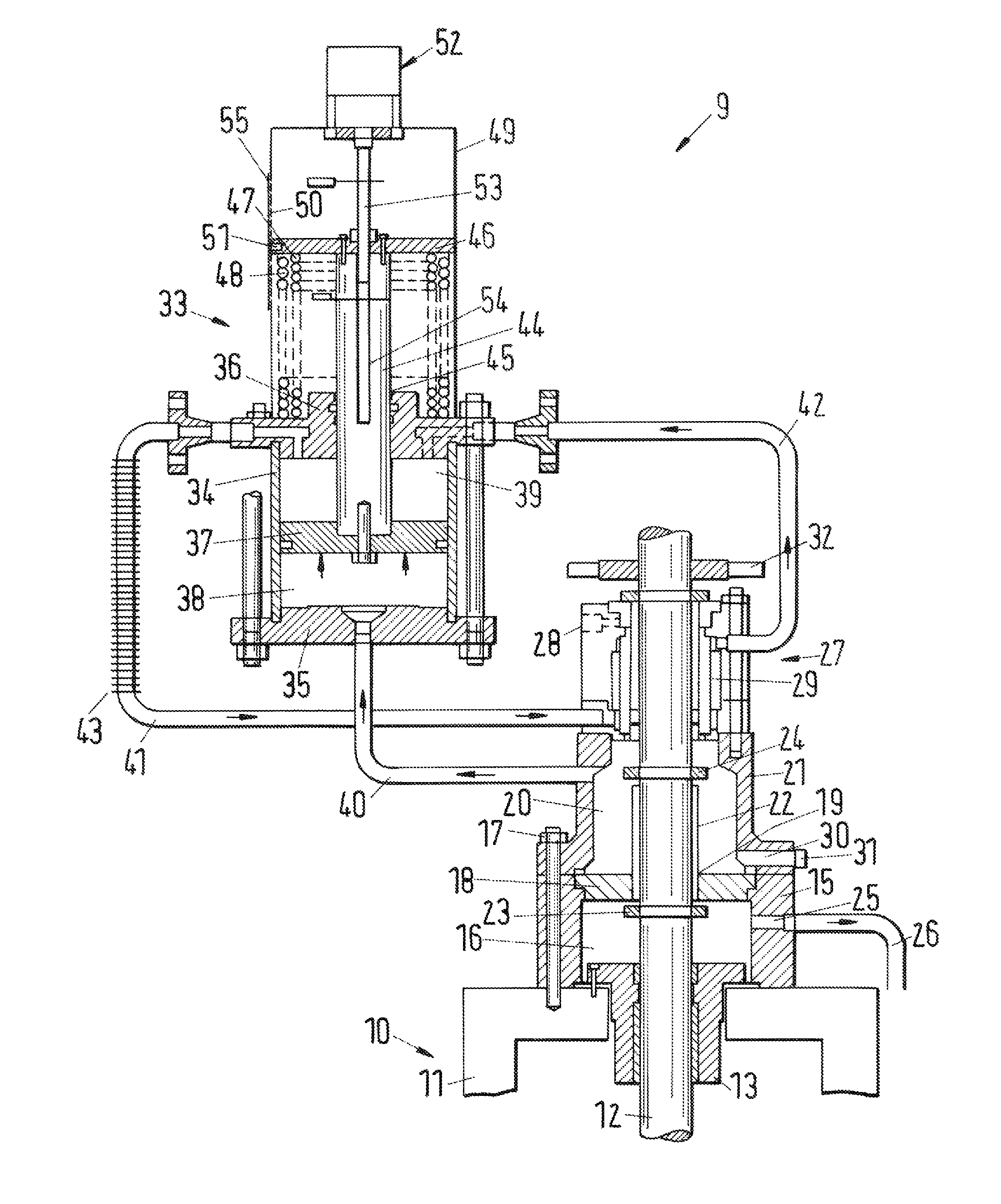

Sealing arrangement for a rotating shaft

ActiveUS9482345B2Prevent exitGood thermal insulationEngine sealsLeakage preventionLiquefied natural gasEngineering

The invention relates to a sealing system, in particular for sealing pump shafts of vertically arranged pumps for conveying liquefied natural gas (LNG) or other cryogenic fluids below −80° C. The sealing system has a mechanical seal arrangement. A barrier fluid flows through the mechanical seal arrangement at a barrier fluid pressure. The mechanical seal arrangement prevents a sealing fluid from exiting a sealing chamber. The barrier fluid pressure is higher than a sealing fluid pressure in the sealing chamber.

Owner:SULZER MANAGEMENT AG

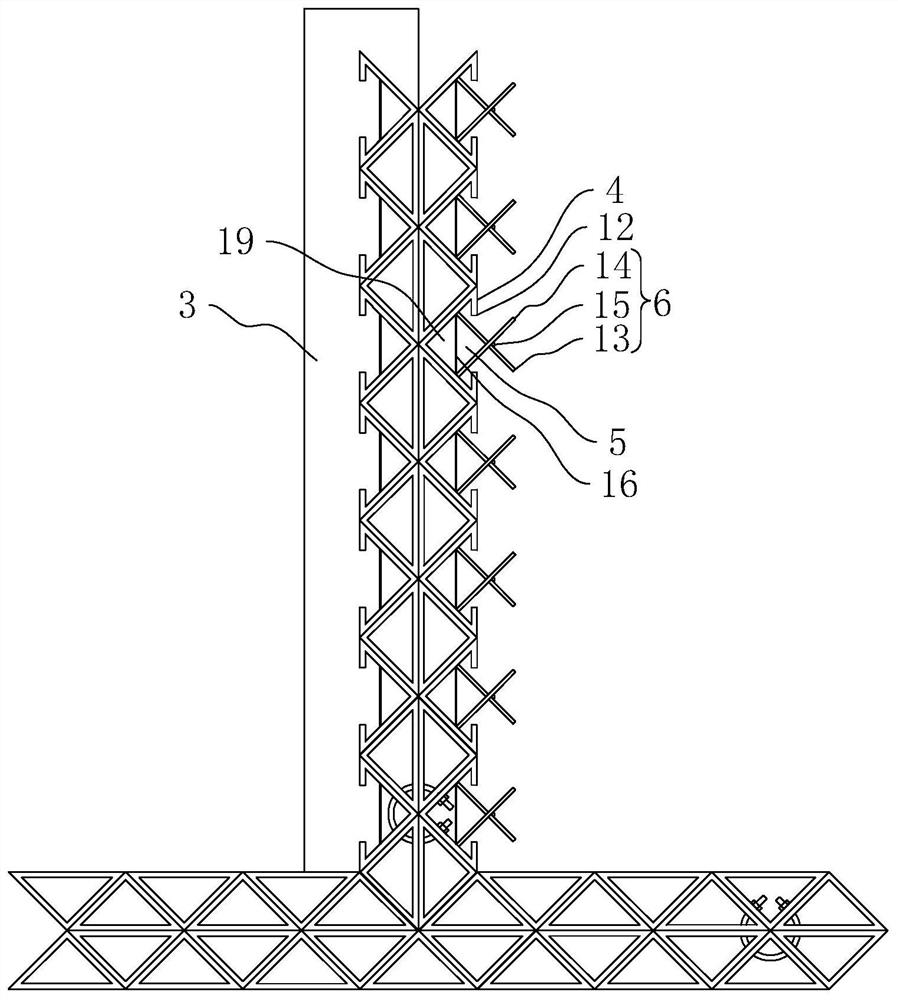

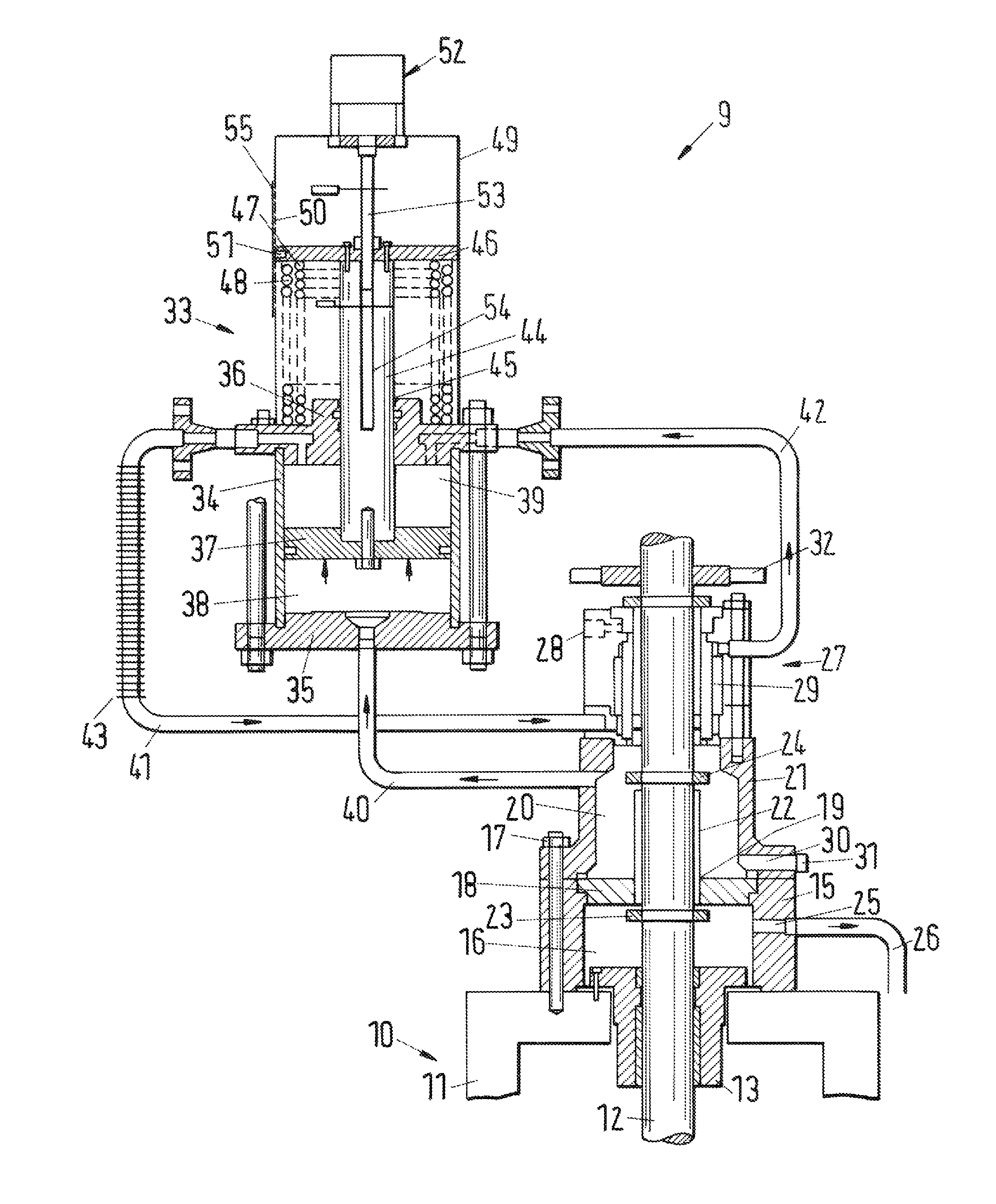

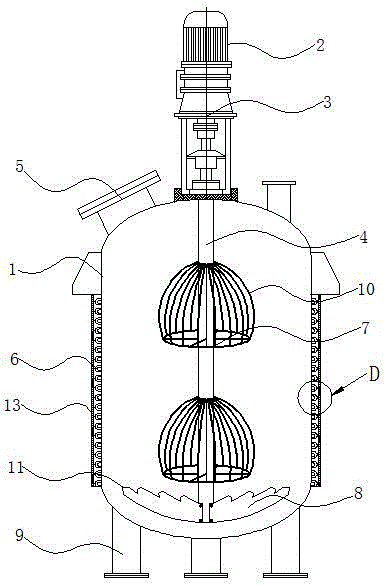

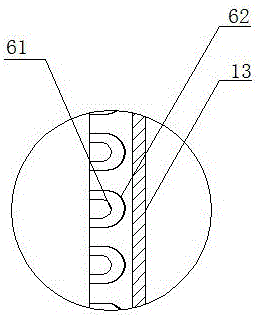

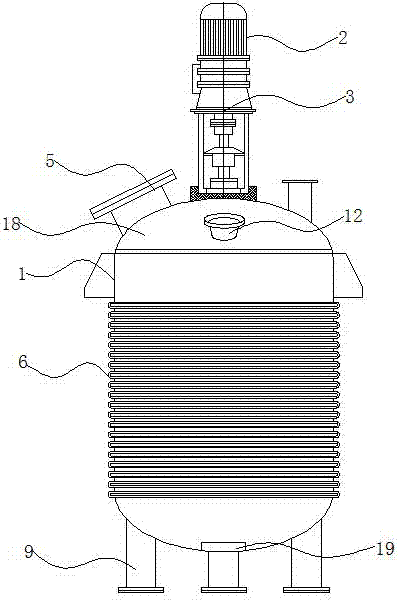

Production of resin with steam heating heat conduction oil circulation heating reaction kettle

ActiveCN104984715BIncrease reaction spaceThorough responseRotary stirring mixersMixer accessoriesThermal insulationReducer

The invention discloses a steam-heating heat-conduction oil cyclic heating reaction kettle for producing resin. The steam-heating heat-conduction oil cyclic heating reaction kettle comprises a kettle body, a kettle cover and a power mechanism, wherein the power mechanism is positioned on the kettle cover; the power mechanism sequentially comprises a motor, a speed reducer, a rack and a stirring shaft positioned in the kettle body from top to bottom; an outer coil tube is arranged at the periphery of the kettle body in a surrounding mode; the outer coil pipe is formed by arranging a heat-conduction oil inner tube and a steam outer tube in a sleeving mode; a heat-insulating layer further covers the outer part of the outer coil tube; at least one cage-type stirrer is arranged on the stirring shaft; and at least one rack type stirrer is arranged at the lowest end of the stirring shaft. The reaction kettle disclosed by the invention is good in stirring effect, improved in reaction efficiency, good in heating effect, high in heating speed, good in thermal-insulation effect, small in heat loss and complete in reaction; and a heating device is set outside, so that the inner reaction space is saved, and the maintenance is convenient.

Owner:JIANGSU JIANYA ENVIRONMENTAL PROTECTION TECH CO LTD

Electromagnetic border composite board and application thereof and reflector lamp antenna

InactiveCN106218133AAchieve reflectionLow costSynthetic resin layered productsAntennasOptoelectronicsMetal

The invention discloses an electromagnetic border composite board and application thereof and a reflector lamp antenna. An antenna reflection board comprises an upper electromagnetic border layer, a core layer and a lower electromagnetic border layer which are sequentially arranged from top to bottom; the core layer is a non-metal layer, and the upper electromagnetic border layer and the lower electromagnetic border layer are metal layers. According to the electromagnetic border composite board, the reflector lamp antenna reflection board is manufactured by replacing an aluminum alloy material with a novel composite material of a multi-layer structure, and therefore not only are the antenna reflection requirements met, but also the cost of the reflection board is greatly reduced; in addition, the weight of the reflector lamp antenna reflection board is decreased, the transportation cost is reduced, and the wind resistance of the product is improved.

Owner:佛山市天磁通天线技术有限公司

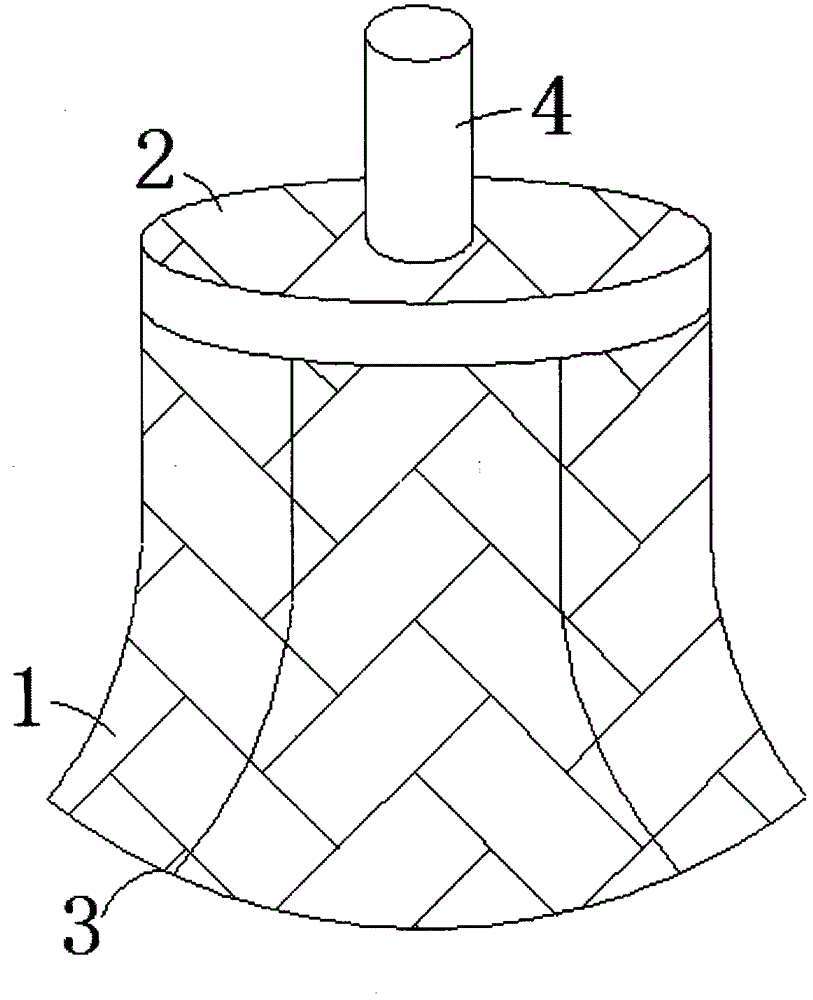

Weaving handicraft lampshade

The invention relates to a weaving handicraft lampshade. The weaving handicraft lampshade comprises a plurality of arc-shaped faces and a lampshade top. An annular lampshade body is formed by combining the multiple arc-shaped faces annularly. The lampshade top is detachably arranged at the upper end of the lampshade body. The inner diameter of the lampshade body is gradually increased from top to bottom. A lampholder is arranged on the upper portion of the inner side of the lampshade body. The upper end of the lampholder is provided with a connection tube penetrating out of the lampshade top. The inner side of the lampshade body and the inner side of the lampshade top are provided with thermal insulating layers which are tightly attached to the lampshade body and the lampshade top. The lampshade body and the lampshade top are both woven by weaving fabric. Compared with the prior art, the weaving handicraft lampshade is resistant to high temperature and long in service life, the lampshade body is not transparent to light, and the render effect is improved.

Owner:张冬梅

PET-SR antibacterial thermal insulation glass film

InactiveCN110643292AGood thermal insulationExcellent riot resistanceFilm/foil adhesivesOrganic non-macromolecular adhesiveThin membraneThermal insulation

The invention belongs to the technical field of membranes, in particular to a PET-SR antibacterial thermal insulation glass film which comprises an antibacterial scratch prevention layer SR layer, a modified PET base layer and an adhesive layer, wherein that glass film of the invention has good thermal insulation, wear resistance and antibacterial performance; according to the invention, the raw material of the film is improved, so that the obtained glass diaphragm has good heat preservation and heat insulation performance and good antibacterial property, and when the automobile glass is impacted by an external force, it will not instantly break into fragments and cause damage to personnel in the automobile. The invention has excellent comprehensive performance and can be widely applied tothe fields of automobiles and furniture building materials.

Owner:浙江磊峰塑料科技有限公司

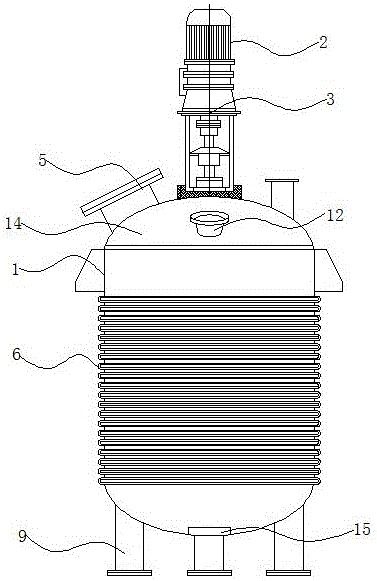

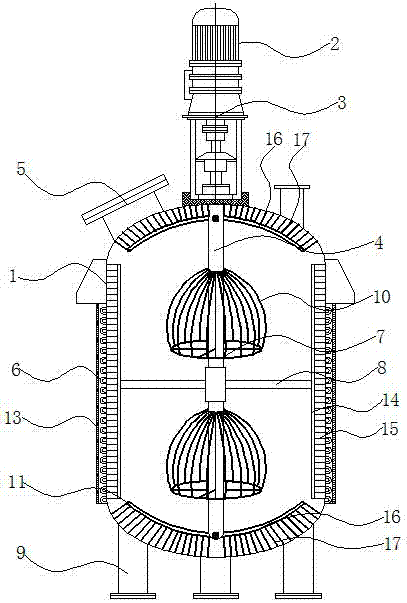

Reactor for resin production with scraper

ActiveCN105056863BIncrease reaction spaceReduce lossRotary stirring mixersMixer accessoriesHeat conductingHorizontal axis

The invention discloses a reaction kettle for resin production with a scraping device. The improvement of the reaction kettle is that an outer coil is arranged around the periphery of the kettle body, and the outer coil is formed by a heat-conducting oil inner tube and a steam outer tube. The outside of the outer coil is also covered with a layer of heat insulation; the stirring shaft is provided with a cage stirrer, and the corresponding two sides of the stirring shaft are horizontally fixed with horizontal shafts, and the end of each horizontal shaft is vertically provided with vertical plates. A welding scraper device 1 is fixed on the outer surface of each vertical plate, arc-shaped plates are also arranged on the top and bottom of the stirring shaft, and a welding scraper device 2 is fixed on the convex surface of each arc-shaped plate; the reaction kettle stirring disclosed by the present invention The effect is good, the reaction efficiency is improved, the heating effect is good, the heating speed is fast, the heat preservation effect is good, the heat loss is small, the reaction is complete, and the heating peripherals save the internal reaction space, the maintenance is convenient, the removal of the scale is simple and convenient, and the equipment can last for a long time Normal operation, less difficult to clean.

Owner:JIANGSU JIANYA ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com