Construction process of cast-in-place foam concrete self-insulation wall

A technology of foam concrete and construction technology, applied in the direction of insulation, walls, ceramic products, etc., can solve the problems of poor flatness, verticality, hollowing of the outer wall decoration layer, insufficient stability, etc., and achieve longer-term and more stable Thermal insulation, good flatness, and load-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

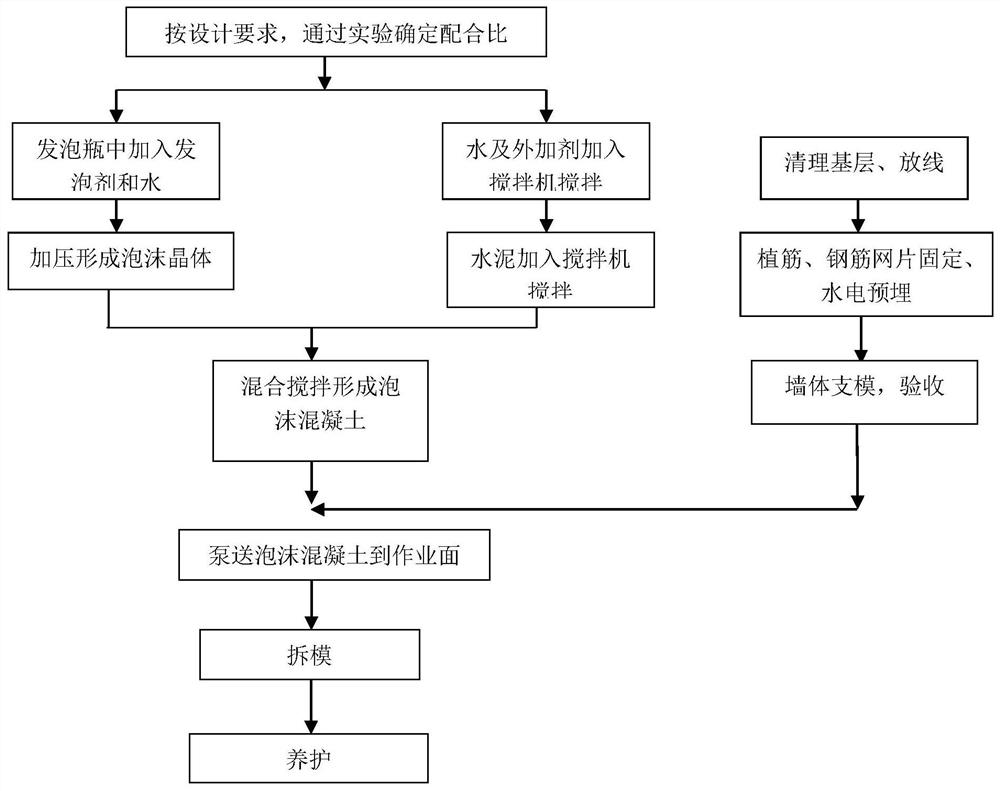

[0021] The construction technology of the cast-in-place foam concrete self-insulation wall of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] combined with figure 1 , the present invention is described in detail.

[0023] The construction process of the cast-in-place foam concrete self-insulation wall, the construction process is as follows: Step 1, according to the design requirements, determine the mix ratio through experiments;

[0024] Step 2, add foaming agent and water into the foaming bottle, and pressurize to form foam crystals;

[0025] Step 3, adding water and admixture to the mixer for stirring;

[0026] Step 4, adding cement to the mixer for stirring;

[0027] Step 5, adding the foam crystals into the mixer for stirring, mixing and stirring to form foam concrete;

[0028] Step 6. Clean up the base layer and set out the wires;

[0029] Step 7, planting bars, fixing steel mesh, pre-embedding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com