Reactor for resin production with scraper

A technology of reaction kettle and scraping material, applied in mixers with rotary stirring device, chemical/physical/physical-chemical stationary reactors, dissolution and other directions, can solve the problems of narrowing reaction space, affecting reaction efficiency, poor heating effect, etc. , to reduce the loss of heat, increase the reaction space, and improve the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

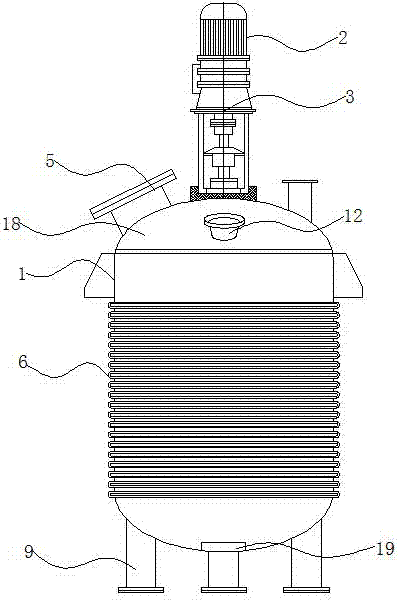

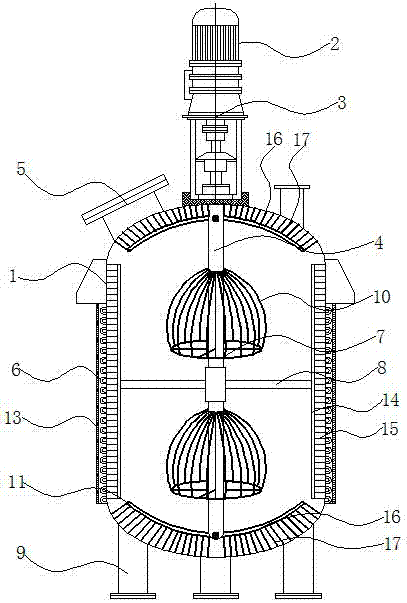

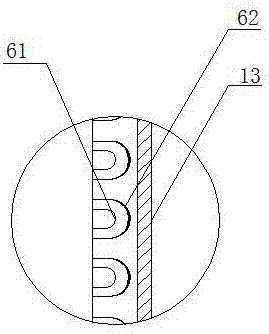

[0020] Refer to attached Figure 1-5 A kind of reaction kettle for resin production with a scraping device shown, comprises a kettle body 11, a still cover 18 and a power mechanism, and a feed port 5 and a perspective mirror 12 are also arranged on the described kettle cover 18, and the perspective mirror 12 is used for In order to observe the reaction situation inside the reaction kettle, a discharge port 19 is provided at the bottom of the kettle body 11, and a three-legged support base 9 is arranged at the bottom of the kettle body 11, and the three-legged support base 9 forms a stable triangular structure , play a strong support to the reactor kettle body 1, the power mechanism is located on the kettle cover 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com