Composite heat-insulation flexible facing sheet for building wall as well as processing technology and application of composite heat-insulation flexible facing sheet

A technology for flexible facings and building walls, applied in the field of building wall decoration, can solve problems such as insufficient heat insulation performance, and achieve the effects of light weight, improved practicability, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

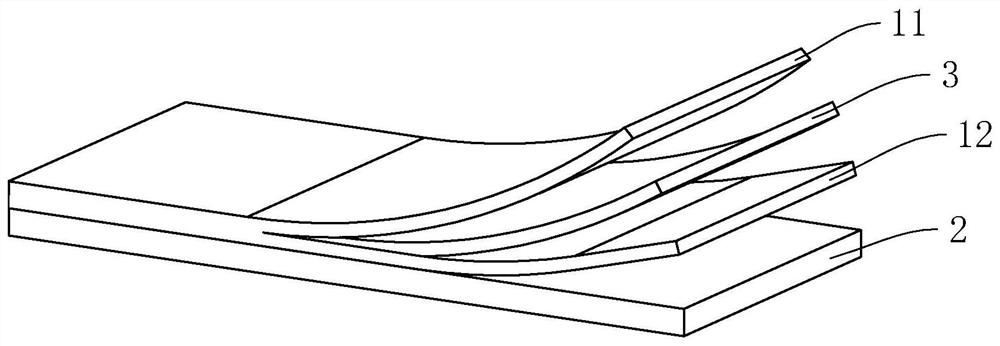

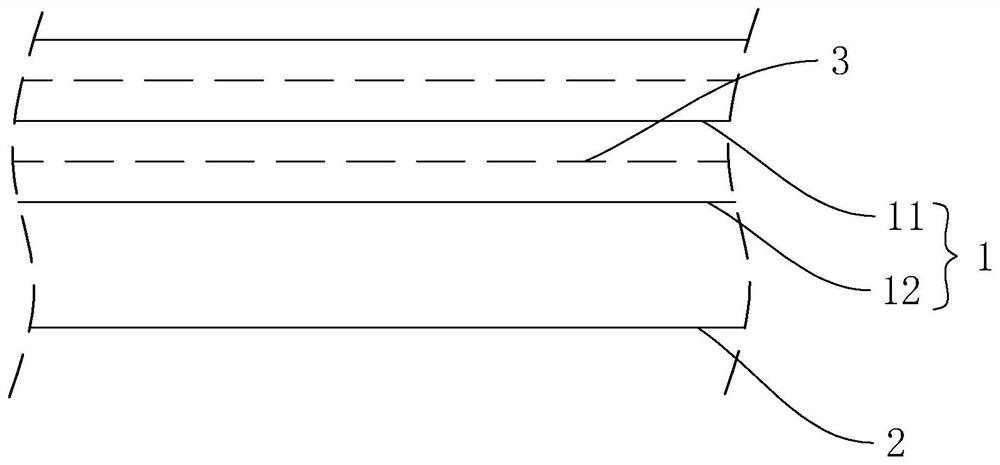

[0061] A building wall facing flexible insulating sheet composite including soft porcelain veneer layer, fixed in the back surface of the insulating layer facing the underlying soft porcelain, porcelain veneer layer is provided with a soft layer toughened, the toughening layer is a fiberglass mesh.

[0062] A soft material layer porcelain veneer ratio shown in Table 1.

[0063] Wherein the dispersant is selected from NOPCO5040; defoamer selected Nuo Puke SN154; cellulose ether is selected from Ashland 250HBR; emulsion is selected from BASF 7640; blast furnace slag selected Tangshan Cheng Building Material; is selected from Hebei rich tailings slag plant; wollastonite powder wollastonite needle-like powder, and is selected from Guangyuan; selected from quartz sand Mines Ltd. Shijiazhuang Jian Tong; fiber PP fiber, and are selected from Thai An Haosong fiber Co., Ltd; thickener selected from the Dow TT-615; pigment selected from the LANXESS Bayferrox pigments.

[0064] Underlying in...

Embodiment 2-4

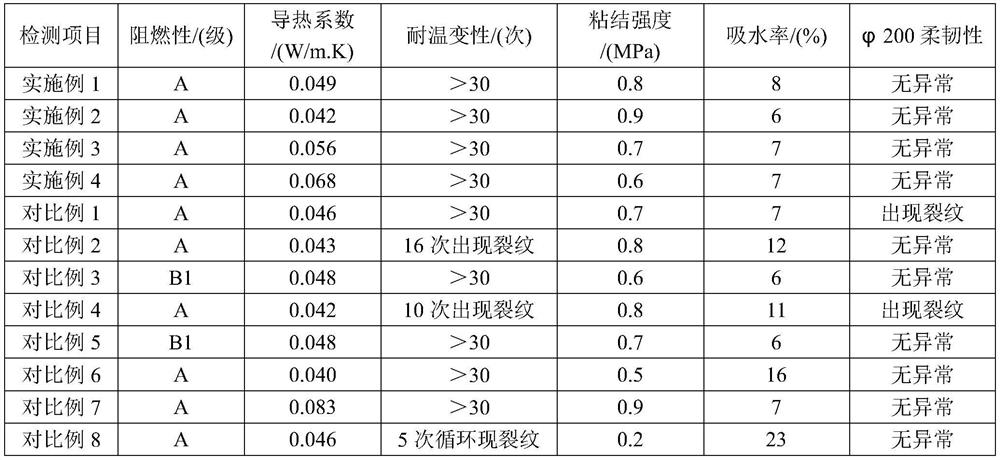

[0075] A construction wall body is composite subjected flexible finish sheet, and the difference between Example 1 is that the soft porcelain rejection layer, the material ratio of the insulating underlayer, the material ratio of the soft porcelain As shown in Table 1, the material ratio of the insulating bottom layer is shown in Table 2, the remainder and the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com