Green energy-saving fabricated building wall part

A building wall, energy-saving technology, used in building components, building structures, buildings, etc., can solve the problems of troublesome assembly, poor thermal insulation and sound insulation, etc., and achieve easy assembly, good sound insulation, and thermal insulation. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

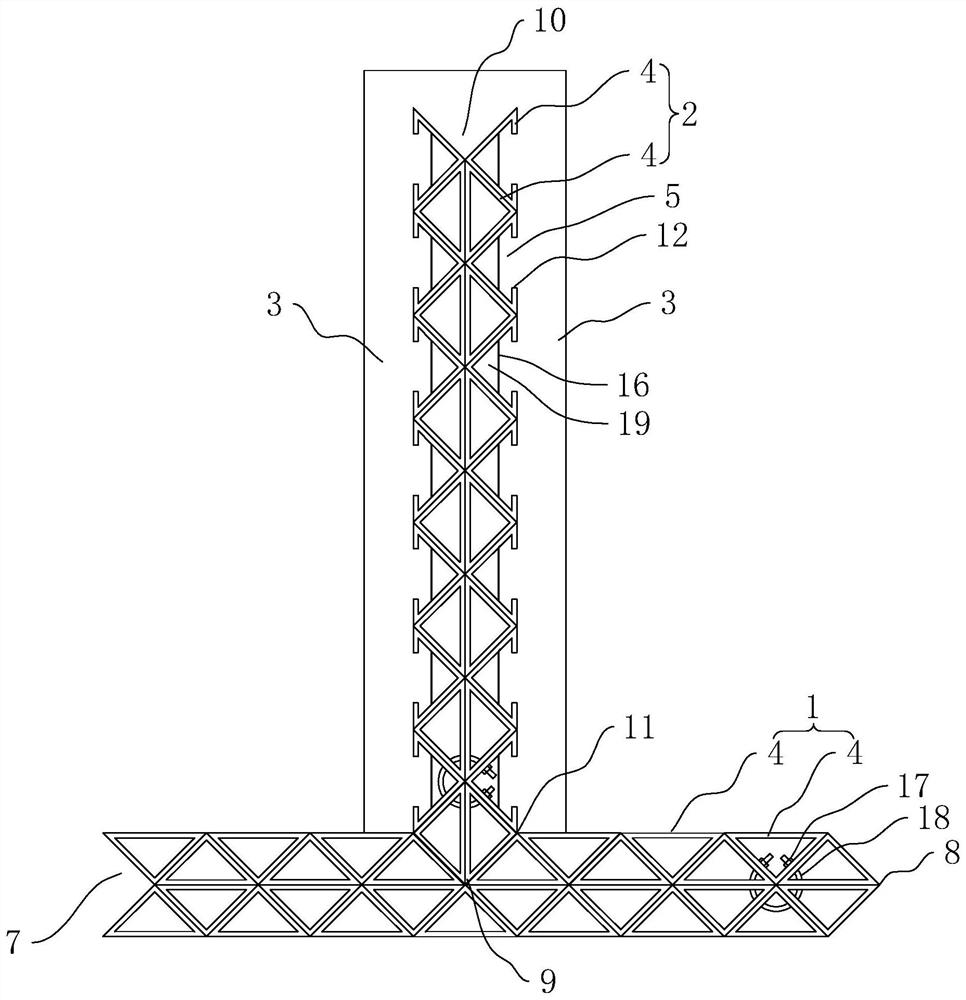

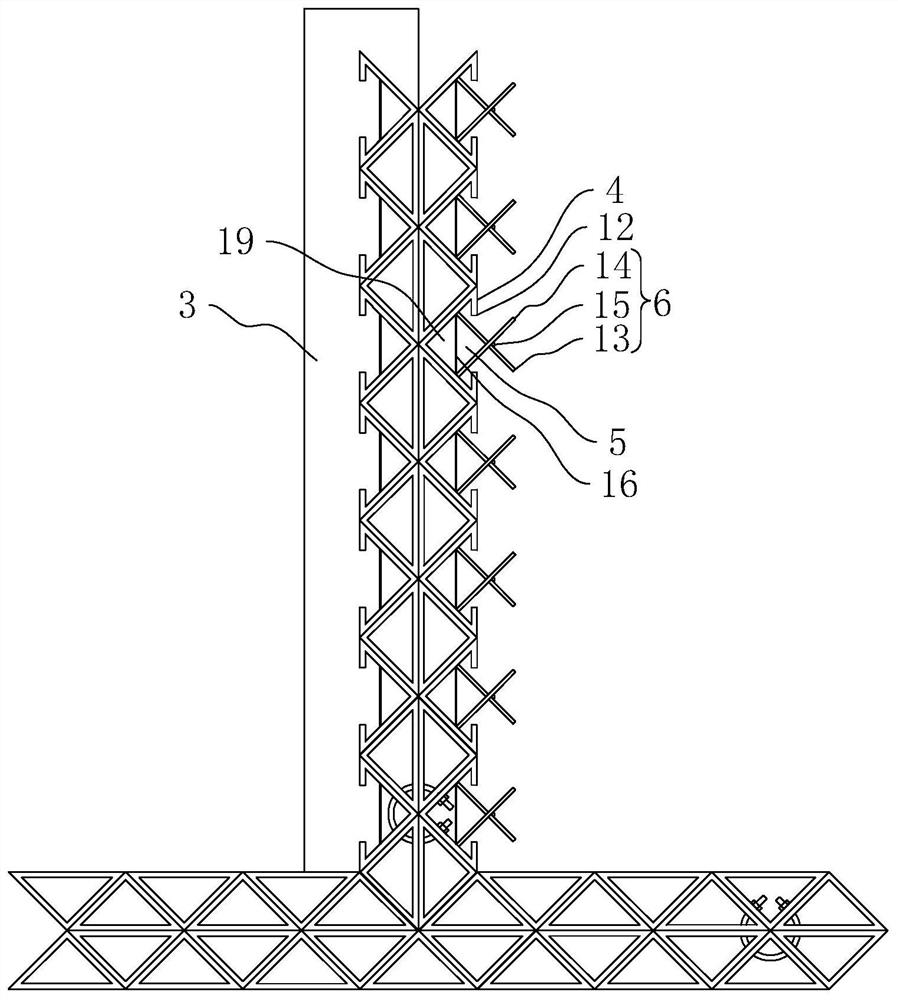

[0029] The following is attached Figure 1-2 The application is described in further detail.

[0030] The embodiment of the application discloses a green energy-saving prefabricated building wall component. refer to figure 1 , the green energy-saving prefabricated building wall components are composed of horizontal component 1, vertical component 2 and concrete cast-in-place layer 3, in which the horizontal component 1 is used as the floor skeleton, the vertical component 2 is used as the partition wall skeleton, and the two sides of the vertical component 2 After connecting the cast-in-place concrete layer 3, a partition wall is formed.

[0031] refer to figure 1 , the horizontal component 1 and the vertical component 2 are all spliced by a number of metal straight triangular prism tubes 4, the straight triangular prism tubes 4 used in the horizontal component 1 and the vertical component 2 have the same shape, are isosceles right angles Triangular prism. The horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com