Mounting structure for dry-hanging keel of cement fiberboard external wall system

A technology of cement fiber board and installation structure, applied in the field of building exterior decoration, can solve the problems of thermal insulation, poor waterproof and moisture-proof performance, blank cement fiber board, low installation efficiency, etc., so as to improve installation accuracy and installation efficiency, and achieve good thermal insulation and heat insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

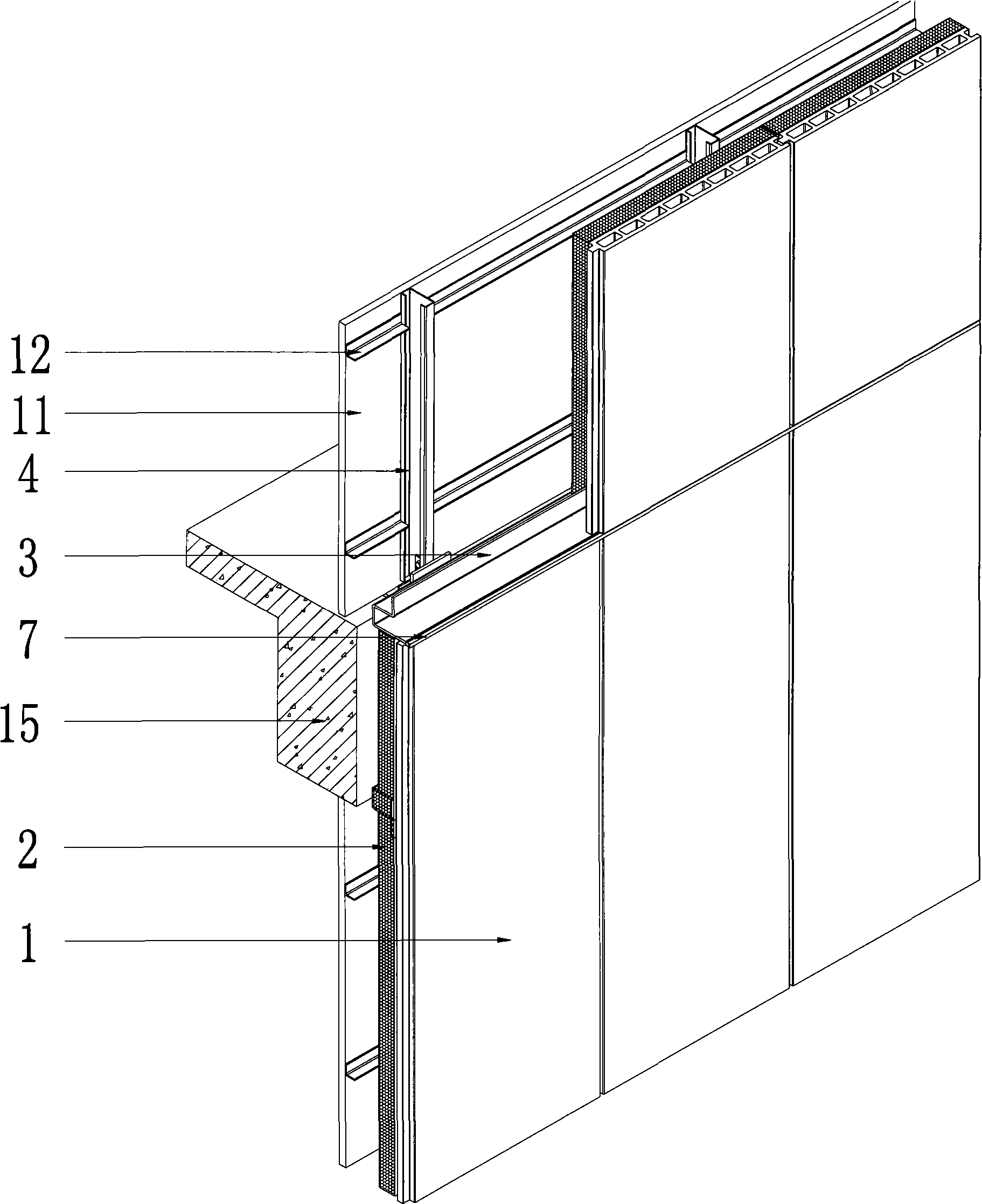

[0022] refer to figure 1 , The main materials of this structure are: cement fiber board 1, insulation board 2, beam 3, angle steel beam 12, column 4, interior decoration material 11, etc. The cement fiber board 1 and the interior decoration material 11 are all installed on the keel system formed by the angle steel beam 12 , the beam 3 and the column 4 . The pendant 5 is a Z-shaped steel pendant 5, the beam 3 is a U-shaped steel beam 3, the column 4 is a steel column 4, and all loads are transmitted to the main building structure by the steel keel.

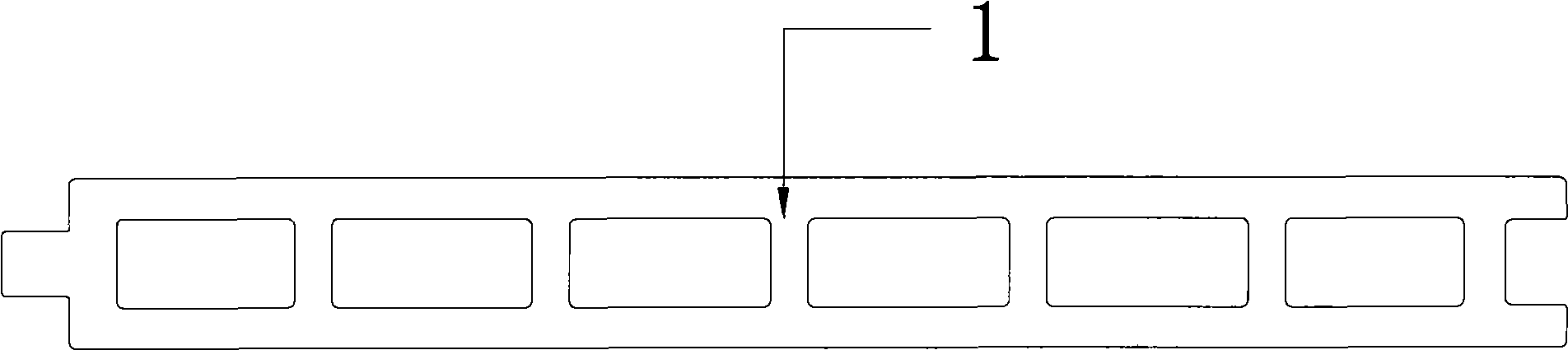

[0023] refer to figure 2 , Both ends of the cement fiberboard are provided with overlapping structures, and the overlapping joints can maintain good waterproof performance after being caulked by the sealant 7.

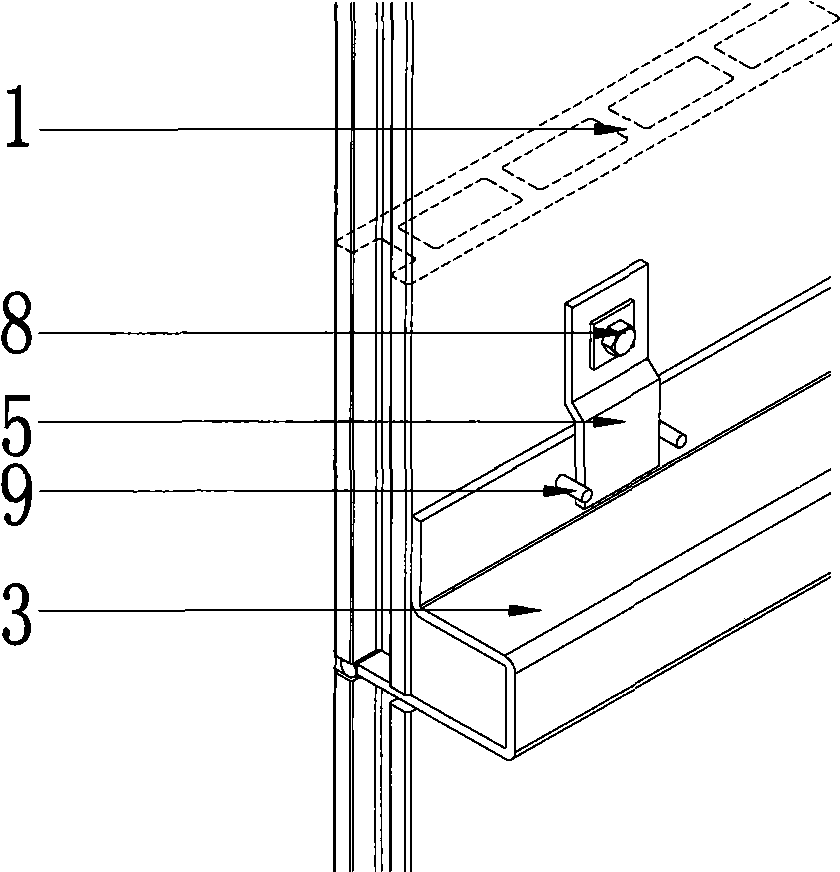

[0024] refer to image 3 , the cement fiber board 1 back is connected by bolt 8 and Z-shaped steel pendant 5, and Z-shaped steel pendant 5 is then tightly fastened on the U-shaped steel crossbeam 3 and adopts location p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com